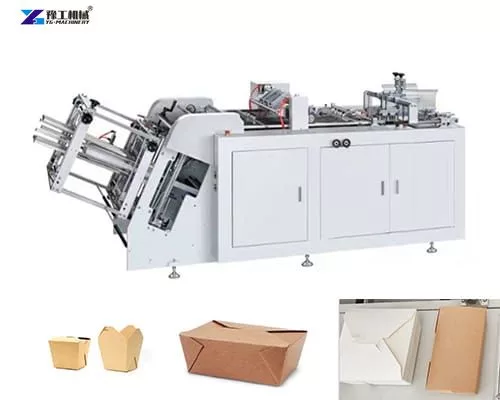

Paper carton erecting machine is the equipment to fold cardboard into boxes as containers to package hamburgers, french fries, fried snacks, desserts, and other food. The carton erecting machine uses a water-based adhesive that is food-grade. The burger box-making machine can automatically finish carton forming, folding, and gluing. It is an ideal machine for paper box forming. Besides, it can produce different sizes and shapes of paper boxes by changing different molds of carton forming. If you are looking for the equipment to make boxes, get in touch with us freely.

Technical Parameters of the Paper Carton Erecting Machine

| Box length | 100-450mm |

| Box angles | 5°-40° |

| Box width | 100-580/385mm |

| Edge banding height | 15-200mm |

| Occupancy of machine | 1.2*4m |

| Product speed | Max 180pcs/min |

| Bonding/gluing device | Water-based adhesive |

| Paper thickness | Max 1.5mm |

| Electrical requirement | 3kw/h |

| Air requirement | 6kg/cm²*200L/min |

| Equipment size | 3.48*1.32*1.5m |

| Weight | 1.5T |

| Packaging measurements | 3.55*1.35*1.7m |

Note: The production speed above is the speed under ordinary conditions, but the actual speed will be different according to the real specifications and the materials.

Benefits of the Paper Box Forming Machine

- Reasonable design, compact structure, high-cost performance, high automation, accuracy

- PLC intelligent control system, simple to operate and easy to set up parameters

- High efficiency and production speed can realize 180pcs per minute

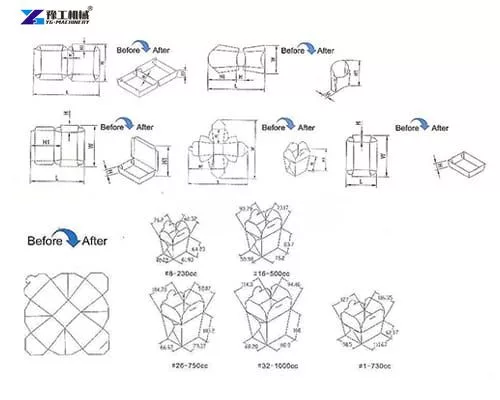

- The equipment can produce different boxes with different specifications by changing molds

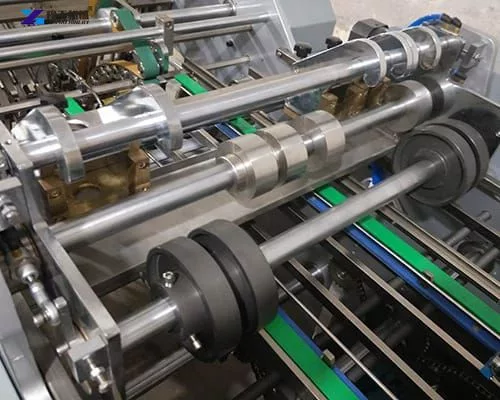

- High-quality sealed bearing prevents dust and liquid from entering and affecting bearing life, long service life, and good stability.

- Automatic stopping device if no cardboard to making boxes on the machine, in case of unnecessary damage during the production process.

- The mold uses pine material, efficiently changing molds.

The Principle of the Carton Erecting Machine

The paper output mechanism takes out the pre-printed and cut cardboard sheets from the paper rack sends them to the conveyor chain, and then sends them to the forming mold. During this process, the cardboard sheets are coated with water-based glue. The position of the glue can be adjusted at will, and the amount of glue applied can be adjusted during production without stopping the machine. After the glued cardboard pieces are formed, they are sent to the collector, automatically stacked counted, and processed as scheduled. The stack quantity is automatically marked without downtime.

Components of the Paper Box Making Machine

The paper carton erecting machine consists of a paper feeding system, gluing system, forming device and box collector, and box collecting frame. The paperboard feeding part adopts a chain drive to ensure smooth running and hard-wearing. Every unit is separated to reduce noise and workload, increasing stability. The gluing part uses a water-based adhesive to coat the roller with foam and apply it to the paper glue position. The height of the forming mold is adjustable and various specifications and shapes can be made, such as the taper box and flapped hamburger box. The carton collecting frame can be adjusted by hand wheel, which is simple and convenient.

Characteristics of the Carton Erecting Machine

- It uses a thermal bonding system to produce aluminum foil and double PE-coated paper boxes.

- Apply PLC system to control and produce paper boxes. It will stop automatically if there is no paperboard for forming boxes, safe and convenient.

- The burger box-making machine can install additional counters according to the requirements of customers.

- Water-based adhesive is food-grade, which is safe for the human body.

- All of the molds are made of pine material, so they can be more durable.

- Suitable for different sizes and shapes of paper boxes by using different carton forming molds.

Paper Carton Erecting Machine Price

The price of a burger box making machine is related to the quality, function, freight, and other factors. Most buyers tend to choose equipment with high-cost performance. Normally, the higher quality needs to spend more cost, so the price is higher. Moreover, the functions it owns more, the price is also will be added. For example, the PLC system requires more cost than the ordinary system. Besides, the freight for the transportation is also a part of the whole price. It is related to the machine’s weight, size, and transportation method. In short, people can choose a suitable machine on the basis of the real situation.

Paper Carton Erecting Machine Manufacturer and Supplier

YG Machinery is a professional paper production machine manufacturer and supplier. In addition to carton erecting machines, we also provide paper cup forming machines, paper straw machines, paper plate machines, paper cup sleeve machines, paper cup flexo printing machines, paper cup roll die cutting machines, coffee cup making machines, paper cup bowl lid making machines, paper bowl making machines, paper tube core making machines, non-woven bag making machines, tissue paper manufacturing machines, paper bag machine line, etc. Contact us to learn more information about the equipment you are interested in.