The pet blowing machine is a machine for blowing plastic bottles. The equipment mainly blows plastic pellets or preforms processed by PET preform injection molding machines into bottles. At present, most of them use the two-step blowing method in which the raw materials are first made into preforms and then blow molded. The pet bottle making machine mainly relies on air pressure to blow air into the heated preform. Depending on the degree of production automation, pet blowing machines are divided into two types: semi-automatic and fully automatic. PET plastic bottles made by plastic bottle manufacturing machines can be used in medicine, food, beverage, cosmetics, and other industries.

PET Blowing Machine Overview

Blowing material: PP, PE, PET, PC, and other materials.

Application: Mineral water bottles, beverage bottles, cosmetic bottles, medicine bottles, mineral water bottles, lampshades, and other plastic products.

Model: automatic equipment, semi-automatic equipment.

Capacity: one out of one, one out of two, one out of four, one out of six, one out of eight (one out of one means that only one preform can be processed at a time).

Customized molds: Yes, Yugong provides a variety of plastic bottle molds, and we can also customize molds for you according to your needs.

Related: Why use PET material to make plastic bottle preforms?

Classification of PET Bottle Making Machines

According to different classification standards, blow molding machines have a variety of classifications. It can be classified according to the degree of automation and application after molding.

Degree of automation: According to the degree of automation, pet blowing machines mainly include semi-automatic and fully automatic blowing machines. The semi-automatic blow molding machine needs to preheat the preform and put it into the mold to blow the bottle into the desired shape. The fully automatic plastic bottle manufacturing machine can complete the whole process of preheating and blowing, which greatly speeds up the production efficiency.

Application classification: According to the different application scope of plastic bottles, there are water bottle making machine, oil bottle making machine, medicine bottle making machine, 5 Gallon Bottle Blowing Machine, and Water Bottle Filling Machine, etc.

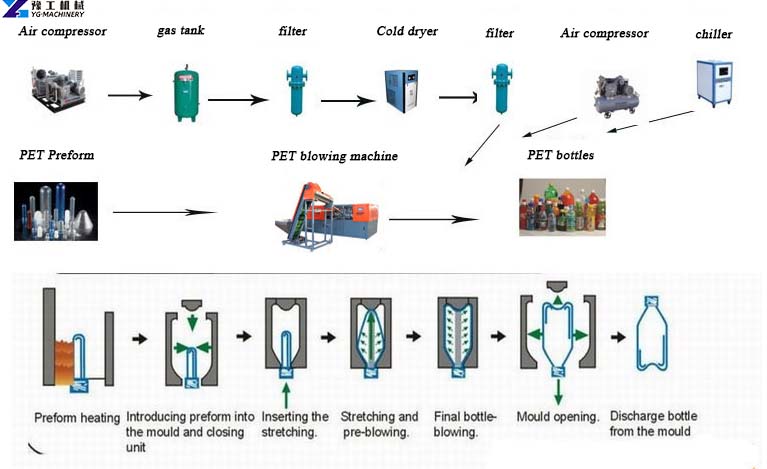

PET Bottle Making Machine Production Process

1. Preheating. Heat the finished PET bottle embryo at a suitable temperature to keep the inner and outer walls of the embryo evenly heated. Reheating the embryos requires cooling the bottle mouth at the same time.

2. Blow molding. The uniformly heated preform is transported to the blowing mold, and sterile high-pressure gas is blown into the preform to stretch the preform along the shape of the mold. Blow up to close to the mold and then cool.

3. Demoulding. After blowing the bottle, exhaust and demould.

4. Conveying and packaging. The formed PET bottles are conveyed to the next station by the conveyor belt, pulled up by the lower bottle cylinder, and blown out. If water is to be filled immediately, the PET bottles can be transported to the water filling machine for filling.

Advantages of PET Blowing Machines

- Automatic bottle blowing, automatic man-machine interface control, easy operation, stable machine operation, and fast bottle blowing speed.

- The structure is simple, and the automatic plastic bottle manufacturing machine includes three modules: a preform feeder, a preform unloader, and the main machine. Different main bodies connect with conveyor belts, which reduces personnel contact and is clean and hygienic.

- The air pressure line and the air blowing line are two parts, which meet the different needs of blowing and action air pressure.

- Constant temperature control, the heating process will not cause the temperature to be too high to damage the preform and ensure the quality of the bottle when it reaches the required temperature of the bottle.

- Flexible mold replacement. After many experimental designs, the pet bottle-making machine produced by Yugong can change different molds to make different types of bottles.