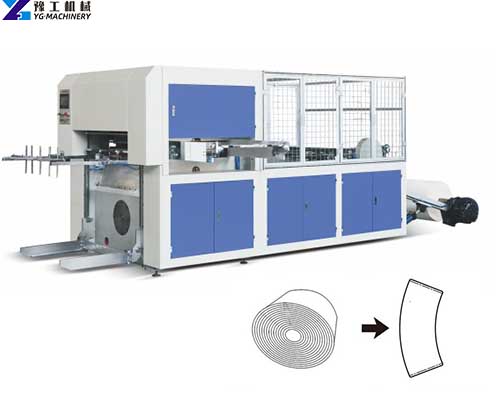

The automatic paper plate machine is developed according to market demand to produce plates made of paper or aluminum foil. By changing molds of different shapes and sizes, it can produce round or square dishes of different specifications and shapes. The equipment has multiple functions such as automatic paper feeding, heating, forming, counting, and collecting. YG also provides other paper cup and paper plate making equipment such as paper cup forming machines, printing machines, die-cutting machines, and cup sleeve machines. If you are interested in an automatic paper cup and plate machine, please contact us.

Automatic Paper Plate Machine Parameters

| Production capacity | 50-85 pcs/min |

| Paper specification | 100-400 g/smBase paper, cardboard, or other |

| Plate specification | 5inch-9inch |

| Voltage | 220V/380V, 50HZ, 3KW |

| Air supply compression | Air pressure: 0.8 Mpa, Air out-put: 0.2 cbm/min |

| Air compressor | Air pressure: 0.5-0.6 Mpa, Air out-put: 0.8 cbm/minCylinder: 150m |

| Packing size | 2500*800*1300mm |

| Weight | 800kgs |

Paper Plate Production Style

The paper plate machine can produce various square, round, and special-shaped paper plates. You just need to change the forming dies of different shapes and sizes. YG supports the customization service of paper plate molds. Please send us a drawing of the size and shape of the paper plates you want to make. YG will customize molds for you according to your needs.

What About The Automatic Paper Plate Machine Price?

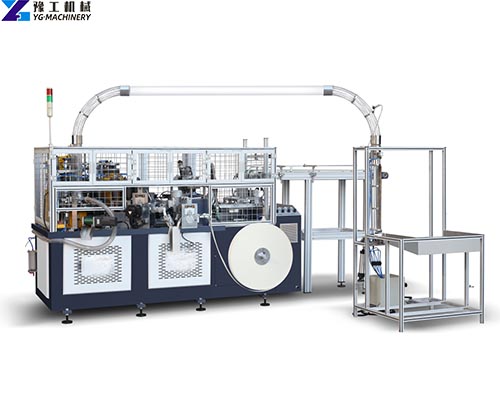

YG provides not only fully automatic paper plate machines but also small and large plate making machine. Below lists the pictures of the semi-automatic paper plate machine, please check. Due to the different degrees of automation and models of paper plate machines, paper plate machines’ prices are different. If you want to know the fully automatic paper plate machine price, please leave us a message.

Main Features Of Automatic Paper Plate Machine

- Adopt PLC control panel, touch screen, easy to operate.

- The automatic paper plate machinery adopts the mechanical paper feeding method. It is more stable than traditional paper-feeding technology, and the scrap rate is greatly reduced.

- The automatic paper plate equipment has multiple functions such as automatic paper feeding, heating and forming, constant temperature control, and automatic counting.

- This machine can equip with a packaging machine, labeling machine, and other equipment to meet large-volume automatic production.

- Using a fast hydraulic system, it is faster, more environmentally friendly, and energy-saving than ordinary cylinders.

Automatic Paper Plate Making Machine FAQ

yes, we support it.

It mainly depends on the complexity of your mold, please consult YG for details.

Yes, YG also provides paper cup machines, coffee cup machines, tea cup machines, printing machines, paper bowl machines, die-cutting machines, and other equipment.

It adopts the standard export wooden box. And we will paste the shipping mark on the wooden box before transportation.

All molds are customized according to customer needs, and the delivery time is about 15~30 days.

YG provides a one-year warranty to all customers. If there is a failure not caused by improper operation within the time limit, YG will repair, replace and send accessories free of charge.

YG Paper Cup and Plate Machine Manufacturer

YG provides customers with an all-around, full-series combination of overall solutions. Founded in 2005, YG is an equipment manufacturing company integrating mechanical research and development, manufacturing, and marketing. At present, it has formed a manufacturing solution to provide customers with paper cups, paper plates, paper bowls, and other paper containers. A full set of production equipment includes printing machines, die-cutting machines, molding machines, packaging machines, and other equipment. YG’s paper container production equipment is welcomed by customers. Welcome to call us to inquire about YG equipment.