What is a Shot Blasting Machine?

The automatic shot blasting machine is a kind of equipment for processing the surface of objects. Material object surface treatment equipment also includes grinding machines, sandblasting machines, and other machines. The portable shot blaster machine can achieve the processing purpose by throwing steel grit and steel shot at high speed on the surface of the material object. This electric concrete shot blast machine widely applies in concrete pavement grinding, airport runway, steel plate, municipal pavement, etc. Yugong shot blasting machine manufacturers offer portable shot blasting machines, grinding machines, and sand blasting machines at competitive prices. If you are interested in the machine, please contact us.

Typical Engineering Application

The shot blasting machine is smoothly used for the treatment of floor coatings; decontamination of nuclear power buildings; small-area steel surface cleaning; cross-street bridge coating cleaning; airport demarcation engineering; railway bridge deck waterproofing construction; highway bridge-tunnel pavement roughening, etc.

Asphalt pavement

It is used to improve the roughness and friction coefficient of the asphalt pavement, thereby improving the adhesion of the pavement to ensure the safety of driving. At the same time, the attachments (such as fuel, engine oil, etc.) on the asphalt pavement have nowhere to escape, which can improve the anti-skid performance of the pavement.

Anticorrosive coating of the steel bridge deck

The application of shot blasting technology in the anticorrosive coating of steel bridges cannot be denied. Most bridges under construction and already built will choose to use shot blasting for surface cleaning and roughness treatment before anti-corrosion primer or another spraying. The steel bridge deck treated by the shot blasting process can meet the steel plate cleanliness requirements of SA2.5/SA3. And the roughness can be controlled to meet the user’s coating requirements. The entire process is dust-free and easy to move. It is environmentally friendly and convenient.

Tunnel maintenance

Due to considerations of waterproofing, fire, and oil resistance of materials, the pavement in the tunnel is generally made of cement concrete. But this also puts forward higher requirements on the anti-skid performance of the long tunnel pavement. For the above two problems that are difficult to solve, the shot blasting process is an environmentally friendly treatment method that is simple in construction, small in equipment investment, and effective.

Preventive maintenance of airport runways

The use of pavement shot blasting machines makes it easy and simple to remove tire tracks and markings on concrete and asphalt runways. Tire removal (except rubber), removal of markings, restoration, and increase of the surface roughness of the airport runway, and improvement of the friction coefficient of the runway are all within the processing range of the road shot blasting machine.

Municipal roads and paved roads

All kinds of road paving in the city can be cleaned by a shot blasting machine. Remove the markings and markings of the road surface, and the road surface can be roughened at crossroads with heavy traffic to improve the roughness and friction coefficient of the road surface. Reduce problems in road construction.

What is Shot Blast Process?

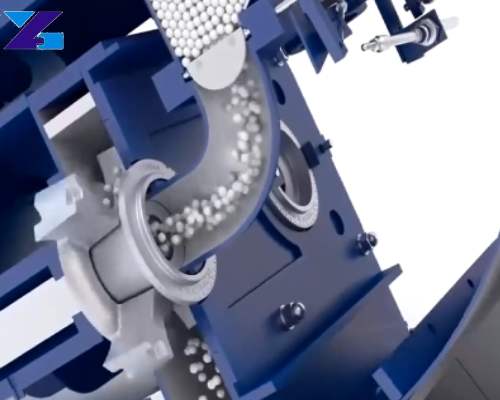

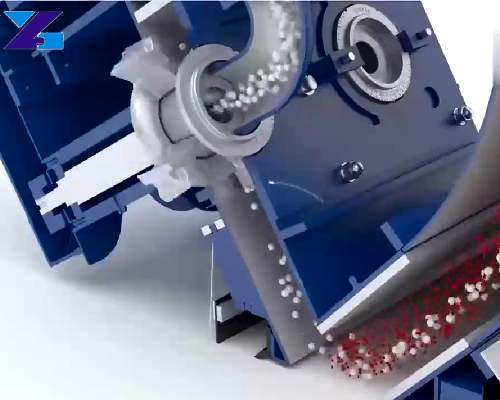

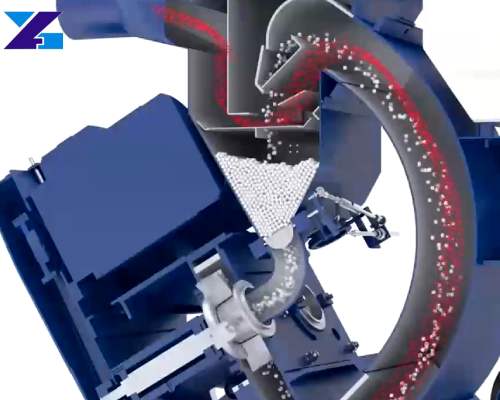

- Close the local sealing device in front of the small portable shot blasting machine to the center of the object being thrown

- Start the roller frame, shot blasting motor, and sand valve to let the steel shot flow from the storage box into the shot blaster machine.

- The blade of the high-speed rotating shot blast machine throws the steel shot, and then thrown steel shot strikes the surface of the object.

- After being ejected from the surface of the object, the thrown steel shot is recovered from the curved pipe into the storage box.

- At the same time, the dust generated in the working process is sucked into the dust treatment device along with the arc-shaped pipe.

YG Shot Blasting Machine For Sale

YG Machinery Co., Ltd. is a manufacturer of shot blasting equipment, sandblasting machines, and environmental dust removal equipment integrating scientific research, development, production, sales, installation, and commissioning services. Our main products include shot blasting machinery, sand processing equipment, environmental protection dust removal equipment, and mechanical accessories. Shot blasting machine, shot blast cabinet, steel shot blaster, floor shot blaster, spinner hanger shot blasting machine, wheel shot blast machine. Sandblasting room, sandblasting equipment, sandblasting box, sandblasting tank, etc.

We provide ideal key equipment for casting, forging, heat treatment, steel structures, containers, machinery, shipbuilding, aircraft, locomotive, road surface, and other industries at home and abroad. In terms of shot blasting machines, the following three models YGPW-270, YGPW-550, and YGPW-850 are very popular. If you have other questions, please contact us. Leave your message to get the shot blasting machine price.

Hot Sale Floor Shot Blasting Equipment

YGPW-270 Shot Blasting Machine

| Item | YPWG-270 |

| The motor of the shot blast wheel | 11KW |

| Walking motor | 0.75kw |

| Diameter of shot blast wheel | φ200mm |

| Work width | 270mm |

| Walking speed | 0.5~30m/min |

| Steel plate surface cleaning efficiency | >80㎡/h |

| Dust removal connecting pipe diameter | 120mm |

| Suggest the diameter of the steel shot | 1.2-1.5mm |

| Consumption of steel shot | 10g/㎡ |

| Dust collector | 6-core automatic counter blowing |

| Dimensions(L*W*H) | 1000mm*300mm*1100mm |

| Weight | 150kg |

YGPW-270 Wheel Blasting Machine

YGPW-550 Shot Blasting Machine

| Item | YPWG-550 |

| The motor of the shot blast wheel | 2×11KW |

| Walking motor | 1.5KW |

| Diameter of shot blast wheel | φ200mm |

| Work width | 550mm |

| Walking speed | 0.5~33m/min |

| Steel plate surface cleaning efficiency | >80㎡/h |

| Dust removal connecting pipe diameter | 150mm |

| Suggest the diameter of the steel shot | 1.5-1.8mm |

| Consumption of steel shot | 10g/㎡ |

| Dust collector | Automatic counter blowing |

| Dimensions(L*W*H) | 1950mm*720mm*1200mm |

| Weight | 595kg |

YGPW-550 Shot Blasting Machine Price

YGPW-850 Shot Blasting Machine

| Item | YPWG-850 |

| The motor of the shot blast wheel | 2×15KW |

| Walking motor | 1.5KW |

| Diameter of shot blast wheel | φ200mm |

| Work width | 850mm |

| Walking speed | 0.5~33m/min |

| Steel plate surface cleaning efficiency | 100-160㎡/h |

| Dust removal connecting pipe diameter | 150mm |

| Suggest the diameter of the steel shot | 1.5-1.8mm |

| Consumption of steel shot | 10g/㎡ |

| Dust collector | 12-core automatic counter blowing |

| Dimensions(L*W*H) | 1950mm*1020mm*1550mm |

| Weight | 700kg |

YGPW-850 Steel Shot Blaster

Shot Blasting Machine Composition

The shot blasting machine mainly includes two parts, the main body of the shot blasting machine and the reverse suction dust collector. The two main bodies are connected by a dust removal pipe. The main body of the shot blasting machine mainly stores the steel shot, and the surface of the object is processed by throwing the steel shot. At the same time, the dust generated in the shot blasting process enters the dust collector through the pipeline.

PW856 Dust Collector

Dust removal system includes dust collector, fan, fan duct, connecting duct between dust collector and host, etc.

The PW856 dust collector is a back-blowing dust removal equipment specially designed for the YGPW-550 road shot blasting machine. It can also be used for dust removal as supporting equipment for powerful road cleaning. The machine is small in size, easy to move, and easy to operate. It is the first choice for pavement cleaning equipment.

The vacuum cleaner cleans the dust through three-way back-blowing, adopts a pulse valve, and uses the principle of sequence control to ensure the smooth circulation of the vacuum cleaner. Use a polyester dust removal hose to ensure that the connection is wear-resistant and reliable. Use imported filter paper to ensure dust removal effect. The vacuum cleaner can work safely and stably for a long time. The drive bearing of the fan adopts imported high-speed bearings to ensure the stability and reliability of the drive.

PW856 Dust Collector Parameter

| Model | PW856 |

| Clean up form | Automatic blowback cleaning |

| Number of filter elements | 8 |

| Hopper | Trolley |

| rated power | 4KW fan + 3KW air compressor |

| weight | 580Kg |

| Dimensions | 2030*870*1500mm |

PW856 Dust Collector

Advantages Compared to Conventional Steel Plate Treatments

- It is environmentally friendly, and the dust generated in the shot blasting process can be automatically recycled without causing pollution to the environment.

- Small mechanical power, low power consumption, no need for transformer expansion.

- Compared with the traditional shot blasting machine, the consumption of steel shot is less.

- Has a very wide range of applications, such as pressure vessels, wind power, nuclear power, pipeline corrosion, and other industries.

Related Product

YG Machinery specializes in manufacturing road construction equipment and road maintenance equipment. For example, road marking machines (including thermoplastic marking machines and cold spray marking machines). Crack sealing machine, road roller, concrete laser leveling machine. Pavement sweeping machine, multifunctional plastic floor spraying machine, non-curing spraying machine, etc.