The concrete mixer with pump is a mobile mixing concrete delivery pump integrating feeding, mixing, and high-pressure pumping. It is a trailer pump and needs to be transported with a trailer. It can be used for long-distance and high-level concrete transportation. The use of a concrete mixer and pumping machine can save a lot of human resources, increase safety and improve construction efficiency. YG also provides electric and diesel-powered small concrete pumps. Please leave us a message to get the concrete pump price.

Parameters of Concrete Mixer with Pump

| Model | YG-350 | YG-550 |

| Theoretical delivery volume | 20-30M3/h | 40M3/h |

| Bone particle diameter | 0.5-40mm | 20-40mm |

| Greatest pressure | 20mpa | 20mpa |

| Bore*Stroke | 180*1000mm | 200*1110mm |

| Motor Power | 45kw | 55kw |

| Oil pump power | 100(column)L/S | 140(column)L/S |

| Delivery pipe | 125mm | 125mm |

| Genset power | 150kw | 150kw |

| Machine size | 6100*2000*2700mm | 6200*2000*2700mm |

| Weight | 5500kg | 6500kg |

The above are the parameters of the YG concrete mixer and pumping machine. For the YG-350 model, its theoretical conveying distance is 100-150m, and its theoretical conveying height is 50m. Please leave us a message to tell us your requirements, and we will match you with a suitable model of machine.

Portable Concrete Mixture Pump Overview

Function: feeding, mixing, high-pressure pumping.

Conveying output: For details, please refer to the parameters of the concrete mixing and conveying integrated pump.

Advantages: Trailer traction, easy to move, directly load the material on the forklift, and mix on site. Reduce the transportation time of watering trucks back and forth, and greatly reduce the construction cost.

Suitable for mixing and conveying raw materials: small and medium-sized large aggregate 1-2, 1-3, 2-4 stone concrete pumping.

Trailer Concrete Mixing Integrated Pump Composition

The trailer concrete mixing integrated pump mainly includes a mini concrete pump and concrete mixer. The mixing part is mainly used for mixing various raw materials, and the pump part is used for high-pressure delivery. Therefore, this equipment is equipment that integrates stirring and high-pressure pumping, and the efficiency is very high.

Related Machine

Small Concrete Pump

Tow Behind Concrete Pump

Why Choose Concrete Mixer and Pumping Machine?

As the mixing pump technology becomes more and more advanced, more and more construction parties abandon the traditional mixer and choose concrete mixture pumps. The concrete mixer with pump consists of a concrete delivery pump and mixing equipment, and the drum mixing equipment can be freely assembled and disassembled with the delivery equipment. After disassembling the drum, it reduces the volume of the mixing pump and the height. If it encounters a cave, a bridge hole, and other low environments, it can pass through smoothly. Therefore, one device can realize the functions of two devices, which is a cost-effective choice for the construction party.

Mini Concrete Mixer with Pump Application

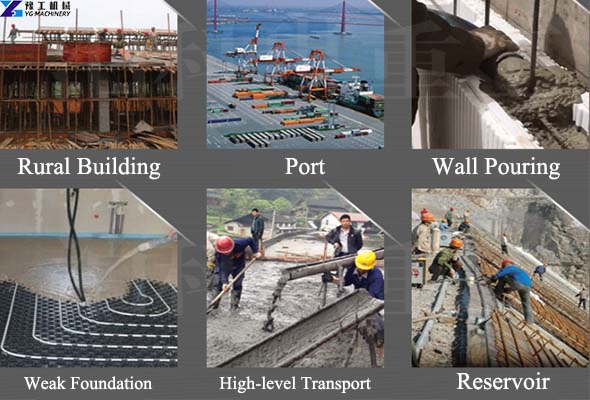

The mini concrete mixer with pump applies in conveying lime mortar, fine stone concrete, etc. It is widely used in road pouring, secondary structural column grouting, foundation treatment, weak foundation, reinforcement grouting, backfilling grouting bolt support in tunnels, subways, mine construction, etc. It can perform on-site mixing and continuous pumping, and its construction efficiency is 4-6 times that of traditional stationary mixers. It has construction characteristics such as convenient movement, and simple operation, and is not limited by narrow construction space and large pouring volume.

Machine Applies in the New Countryside Construction

The concrete mixer and pumping machine is a concrete mixture pump newly developed for rural houses. It makes up for the defects of manual feeding and manual feeding. The equipment integrates mixing and conveying and has the functions of saving labor, time, and effort. It is suitable for the construction of 1-10 layers of cast-in-place concrete in urban and rural areas. It has changed the previous single and inefficient transportation method and is suitable for complex terrain and complex construction sites. The emergence of concrete mixer with pump has solved a series of problems such as expensive labor, difficult construction, poor construction quality, and difficult operation in the past.

Concrete Mixer with Pump Function Introduction

- High power. The equipment’s power system, hydraulic system, and pumping system are reasonably matched to maximize the maximum power of the motor.

- High material absorption. The actual pumping efficiency reaches over 80%.

- High reliability. The configuration is more optimized, and the imported hydraulic parts and electrical components are used to greatly improve the reliability of the equipment.

- Long service life. The smooth S-pipe valve reversing can meet the conveyance of fine concrete or commercial fine stone concrete, and it is not easy to block the pipe, prolonging the service life of the S-pipe.