A rotary drilling rig is a device widely used in hole-forming operations in basic construction projects. It is widely used in the construction of various foundations such as cast-in-situ piles, continuous walls, and foundation reinforcement. The hydraulic rotary drilling machine has the characteristics of fast construction speed, good hole quality, low environmental pollution, flexible and convenient operation, and strong adaptability. Therefore, the machinery is widely used in the construction of utility poles for power grids, signal towers, power generation fans, etc.YG not only supplies rotary drilling rig for sale but also supplies DTH drilling rigs, water well drilling rigs, HDD machines, crawler drill rigs, etc.

Related piling machinery

Pile Cutting Machine

How does the Mud Rotary Drilling Rig Work?

Rotary Piling Rig Parameters

Truck Mounted Rotary Drilling Rig

| Size(mm) | 7900×2260×3100 |

| vehicle quality(kg) | 8000 |

| wheelbase(mm) | 3150 |

| wheelbase(mm) | 1400 before and 1060 after |

| Drilling Depth(m) | 13 |

| Drilling diameter(mm) | 600-1600 |

| Rotation angle | 180degree |

| Walking speed(km/h) | 50 |

| Gear pump model | CBJT2080 |

| hydraulic system working pressure(mpa) | 20-25 |

| Hydraulic system displacement(ml/r) | 80 |

| engine model | 4108 |

| engine power(kW) | 88 |

Machine Lock Rod Rotary Drilling Rig

| Model | YDR150 | YDR200 | YDR260 | YDR300 |

| Working status size (m) | 5.9×2.3×10.5 | 7.1×2.6×12 | 8×2.8×11.5 | 8.8×2.8×12.8 |

| Shipping status size (m) | 8.2×2.3×3.25 | 10×2.6×3.38 | 10×2.8×3.55 | 10.8×2.8×3.65 |

| Overall weight (t) | 17 | 22 | 26 | 28 |

| Maximum drilling diameter (mm) | 1200 | 1400 | 1400 | 1400 |

| Drilling depth(m) | 15 | 20 | 25 | 30 |

| Engine brand | Yuchai | Cummins | Cummins | Cummins |

| Engine model | 4A115Z | 6BT5.9-C150 | 6BTAA5.9-C205 | 6BTAA5.9-C205 |

| Maximum stroke(mm) | 2800 | 2800 | 2800 | 2800 |

| Main hoist maximum lift(kn) | 10 | 15 | 15 | 18 |

| Maximum speed(m/min) | 72 | 71 | 71 | 68 |

| Deputy hoist maximum lift(kn) | 15 | 20 | 30 | 45 |

| Maximum speed(m/min) | 60 | 70 | 70 | 75 |

| The mast tilt left and right(°) | ±5 | ±5 | ±5 | ±5 |

| Forward tilt(°) | 8 | 8 | 8 | 8 |

| Chassis maximum walking speed(km/h) | 4 | 3 | 3 | 3 |

| Maximum grade(°) | 35 | 35 | 30 | 30 |

| Track width(mm) | 500 | 600 | 600 | 600 |

| Track chain pitch(mm) | 154 | 190 | 190 | 190 |

| Chassis length (mm) | 3600 | 3800 | 4200 | 4500 |

| Average ground specific pressure (k Pa) | 66.3 | 77 | 85 | 92 |

Crawler Rotary Drilling Machine

| Size(mm) | 8700/2300/3100 |

| vehicle quality(kg) | 15 |

| wheelbase(mm) | 15 |

| wheelbase(mm) | 600-1800 |

| Drilling Depth(m) | 360 degree |

| Drilling diameter(mm) | 5-8 |

| Rotation angle | 20-25 |

| Walking speed(km/h) | 63/63 |

| Gear pump model | Yuchai4108 |

| hydraulic system working pressure(mpa) | 85 |

| Hydraulic system displacement(ml/r) | gear pump 50/50 |

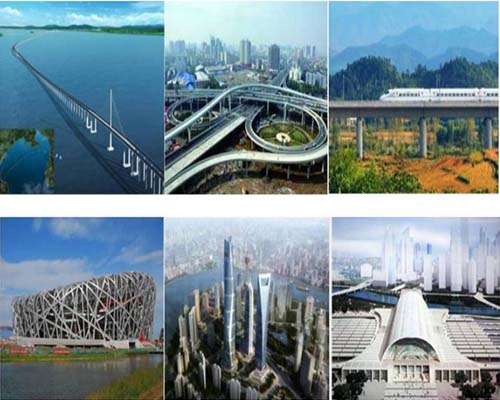

Hydraulic Rotary Drilling Rig Application

The hydraulic rotary drilling rig is suitable for clay, sand, silt, muddy soil, and other soils. The high-torque power head rotary drilling rig is also suitable for the construction of slightly weathered rock. After technological progress, drilling rigs are used in complex formations such as soft soil, hard rock, dense gravel, and boulders. At present, rotary drilling rigs are widely used in highway bridges, railways, water conservancies, urban construction, and other projects.

Three Types of Rotary Drilling Rigs For Sale

According to the torque, engine power, drilling diameter, depth, and other parameters of the rotary drilling rig, the rotary drilling rig can be divided into three categories: small machine, medium machine, and large machine.

Small rotary drilling rig: the torque is 100KN.M, the drilling diameter is 0.5~1m, and the drilling depth is about 40m, which is called a small machine. The small rotary drilling rig is mainly used for slope protection piles of various buildings, some weighing structural piles of buildings and other piles less than 1m.

Medium-sized rotary drilling rig: torque 180KN.M, drilling diameter 0.8~1.8m, drilling depth about 60m. The medium-sized machine is suitable for various highways, railway bridge piles, large buildings, weighing structural piles of ports and wharves, and viaducts in cities Bridges piles, etc.

Large rotary drilling machine: torque 240KN.M, drilling diameter 1~2.5m, drilling depth about 80m.The mainframe is suitable for extra-large bridge piles of various highways, railway bridges, and special structural load-bearing foundation piles of other large buildings.

Three Systems of Mud Rotary Drilling Rig

The rotary drilling rig for sale has three major systems: a power system, a hydraulic system, and an electric system. The power system is the power source for completing the construction and forming holes. All the executive actions of the rotary drilling rig, such as raising, lowering, walking, turning, etc., are driven by hydraulic components. The safe and reliable operation of the hydraulic system is very important to the entire rotary drilling rig. Electricity is needed on the rotary drilling rig, which belongs to the category of the power system.

Advantages of Rotary Piling Drilling Rig

- Strong adaptability. The automatic rotary drilling rig is suitable for various types of coatings such as clay, silt, sand, and muddy soil. Widely used in highway bridges, railways, water conservancy, urban construction, and other projects.

- Fast construction speed. The hydraulic rotary drilling rig for sale relies on the cylinder drill bit with a valve at the bottom to rotate and break along the way, and it is directly loaded into the drill and lifted to the ground, so the construction efficiency is very high.

- Low noise. The noise of mud rotary drilling machine construction mainly comes from the engine itself, and other components hardly produce noise.

- The high degree of automation. During the construction process, there is no need to manually remove and assemble the drill pipe, which reduces the labor intensity and saves human resources.

- Environmental protection. The amount of mud used in hydraulic rotary drilling rig construction is relatively small, and clear water can be used instead of mud for drilling construction in the coating stable area, which greatly reduces the discharge of mud and is conducive to environmental protection.

- Easy to walk. YG provides truck-mounted and crawler-type rotary drilling rigs, which are easy to move.

- High bearing capacity of a single pile. Since the rotary drilling rig relies on the corner edge of the cylinder bottom to cut the soil to form holes, the degree of integration between the pile body and the soil body is relatively high after the pile is formed, so the bearing capacity should be high.