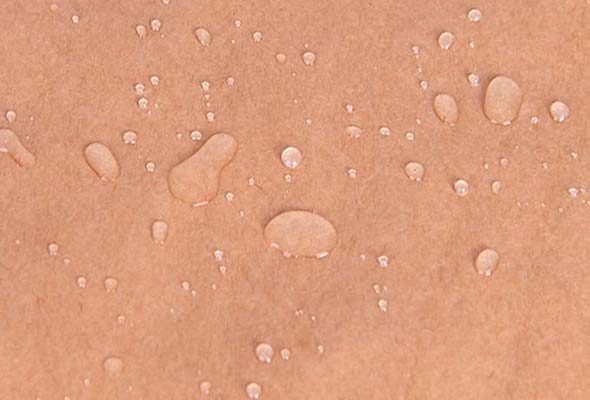

PE coated paper is formed by coating plastic particles on the surface of the paper using a casting machine on the basis of the base paper. Ordinary paper is made of wood pulp, which has strong water absorption but is afraid of moisture and moisture. After lamination, a thin film is formed on the surface of the paper, which can play the functions of moisture-proof, oil-proof and waterproof. PE-coated paper does not use any chemical solvent during processing, which is very environmentally friendly. In the secondary processing, the PE film is directly sealed under hot melt.

Application of PE Coated Paper

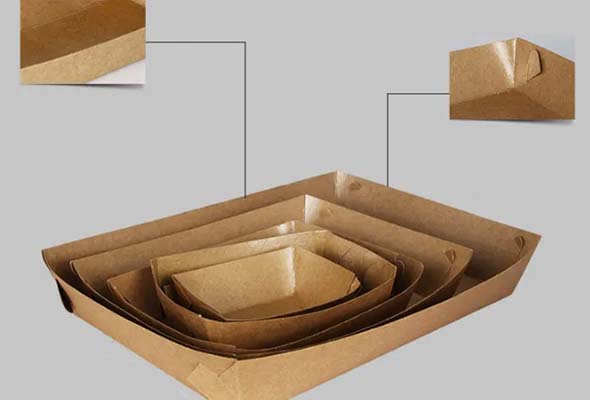

Compared with ordinary paper, PE-coated paper has the characteristics of waterproof and oil-proof. Therefore, PE-coated paper is widely used in food packaging, industrial waterproofing, medicinal material packaging, etc. For example, using PE-coated paper to make paper boxes, paper cups, paper bowls, paper bags, etc. In industry, it is mainly used for moisture isolation and waterproofing. It is often attached to the surface of building materials to prevent moisture from entering the interior of the board.

Single Coating VS Double Coating

According to the number of layers of coating, there are single plastic PE coated paper and double plastic PE coated paper.

Single plastic PE coated paper is kraft paper with PE coated on only one side. Most food packaging bags are only coated on the inside, as excellent printing results cannot be obtained on the coated side.

Double plastic coated paper is a wrapping paper that is coated on the inside and outside. The inner coating is to prevent water seepage, and the outer coating is mainly to avoid condensation of moisture in the air. Double plastic coated paper is usually used to make disposable food containers, such as paper cups, cartons, paper bowls, etc.

A New Alternative to PE Lamination–EAA Heat Sealing Coating

The use of PE coating can achieve the effect of water and oil resistance, but it is difficult to separate the PE coating and the raw pulp, and the paper products are not easy to recycle. EAA heat seal coating is a process to replace PE coating. The heat seal coating not only takes into account the performance of PE-coated paper, but also the paper substrate can be recycled. More importantly, it has also improved water resistance, water vapor resistance, KIT oil resistance, heat sealability, and anti-sticking properties.

Is PE coated Paper Biodegradable?

PE coated paper consists of two layers, one is virgin pulp paper which is recyclable, and the other is PE coated layer. Since the PE coating layer contains PE components, it is difficult to recycle in a short time. However, if PLA is used for lamination, all products containing PLA lamination paper can be recycled.