The hydraulic concrete pulverizer is installed on excavators and is widely used in the demolition industry. It is used for concrete crushing, house demolition, crushing sand and gravel, etc. The crushing tongs separate steel bars from concrete blocks, bend them, and load them onto trucks. Completely mechanized operation, safe and time-saving, improving work efficiency. It has the characteristics of low noise, no vibration, strong power, and meets the needs of environmental protection.

Hydraulic Pulverizer Attachment Parameters

| Model | YG-50 | YG-80 | YG-150 | YG-250 | YG-350 |

| Applicable Model(T) | 3-5 | 6-8 | 12-18 | 20-28 | 30-40 |

| Working Pressure(Mpa) | 24.5 | 24.5 | 31.5 | 31.5 | 31.5 |

| Overall Length | 950 | 1270 | 1620 | 1920 | 2130 |

| Overall Weight(KG) | 240 | 560 | 1150 | 1940 | 2790 |

| Maximum Opening(mm) | 430 | 600 | 745 | 880 | 1030 |

| Blade Length(mm) | 70 | 100 | 120 | 160 | 180 |

| Front Breaking Force(KN) | 178 | 382 | 549 | 725 | 1080 |

| Central Crushing Force(KN) | 282 | 598 | 882 | 1170 | 1750 |

Application Range of Concrete Pulverizer

The hydraulic concrete pulverizer is the best secondary rescue equipment and a powerful tool among similar demolition products. Its hydraulic tongs with powerful crushing ability can quickly decompose reinforced concrete and are specially used for the demolition of buildings, factory beams, and columns. It can also crush the demolished concrete and recycle the steel bars.

How Does the Excavator Concrete Pulverizer Work?

The excavator concrete pulverizer consists of a caliper body, a hydraulic cylinder, a movable jaw, and a fixed jaw. The hydraulic system of the excavator provides oil pressure for the hydraulic cylinder to provide power for the pulverizer. This power makes the movable jaw and the fixed jaw of the hydraulic pliers open and close to achieve the effect of crushing objects.

Excavator Concrete Crusher Product Advantages

- Large opening. The bite force of the large-diameter oil cylinder uses three-groove back support to make the turntable stronger.

- The blade is adjustable. One blade can be used several times, and the double jaws are made of high-hardness wear-resistant steel.

- Equipped with protective cover. The device can be used to intercept flying debris from concrete blocks and steel bars.

- Anti-rust treatment, long service life. All parts are treated with anti-rust treatment to solve problems such as rust and cracking of the product.

- No welding overall. The fuselage is designed in one piece and is made of high-strength plates, making it sturdy and practical.

- The crushing efficiency is higher. Rebar cutters are installed to crush the concrete and cut exposed rebar.

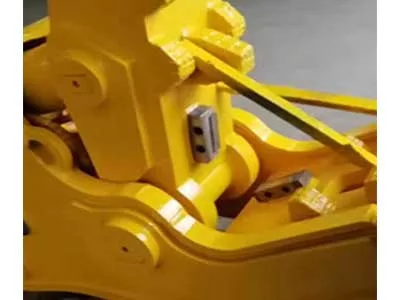

Product Detail Presentation

Jaw teeth

Specially shaped jaw teeth, tight bite, small gap, and anti-slip texture.

Alloy blade

Equipped with a steel bar cutter, the construction is simpler, and the alloy blade is sharp and wear-resistant.

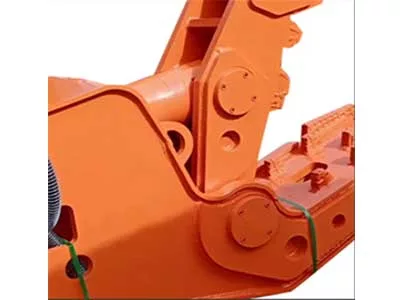

Hydraulic cylinder

Independently produced hydraulic cylinders, with stable work and strong construction power.

High-strength steel plate

The high-strength steel plate is strong and lightweight, and the overall installation is simple. One machine has multiple uses.

Four Reasons To Choose YG Concrete Pulverizer Manufacturers

- The quality is guaranteed. There are checks at all levels, manual inspection, and the equipment is inspected by specialized inspection personnel before leaving the factory, so the quality is guaranteed.

- Factory direct sales. YG excavator attachment manufacturers sell directly to end customers, with obvious price advantages.

- Made of high-quality steel. The crushing pliers are made of imported high-strength plates, with high structural strength and low product weight.

- Guaranteed after-sales service. YG has a dedicated after-sales team to help customers with after-sales management. No matter if you have any problems during use, YG will help you solve the problem as soon as possible.

Concrete Pulverizer VS Hydraulic Breaker Hammer

The concrete pulverizer and breaker are both excavator attachments used to crush concrete, but they also have some differences.

The hydraulic pulverizer tools have a clamp-type structure, which can crush concrete more efficiently and can be crushed into small pieces or pulverized shapes. In addition, the device can be used to remove steel bars in concrete.

The hydraulic breaker hammer is suitable for crushing large pieces of concrete, but cannot break it into small pieces of structure, and cannot recycle steel bars.

Other Demolition Equipment Recommendations

In addition to hydraulic pulverizers, YG also provides other demolition excavator attachments. Such as double-cylinder demolition shears, single-cylinder demolition shears, round pile breakers, square pile breakers, claw-type pile breakers, and other accessories for demolition excavators. In order to meet the needs of customers, YG also provides various tonnage excavators such as small excavators and agricultural excavators.