We often use wet wipes in our daily life. We can use it to clean our face, wipe our phone, shoes, remove makeup, disinfect, etc. So do you know how wipes are mass produced? How is the wet wipes manufacturing process in the factory? Yugong wet wipes making machine manufacturer will introduce the wet wipes production process to you.

Wet wipes manufacturing process

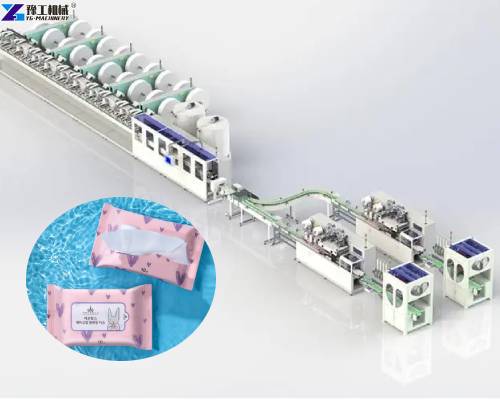

The production of wet wipes usually adopts modern automatic wet wipe machines. From the raw materials of wet wipes to the final production of formed and packaged wet wipes, it needs to go through the processes of feeding, folding, adding liquid, cutting, stacking, conveying, packaging, gluing, conveying, and packing.

The raw material for producing wet wipes can be wet-strength paper or non-woven fabrics. Most wipes are made using non-woven fabrics. Non-woven fabrics are made of fibers and viscose in proportion. The role of fiber is antibacterial and bacteriostatic. The role of viscose is to increase the texture and feel of the non-woven fabric.

Wet wipes are wet because water is added to the dry non-woven fabric. The water here is not the water we usually drink, but pure water filtered by reverse osmosis technology. Inorganic salts, trace elements, minerals, etc. contained in the water are filtered out to form pure water. This increases the shelf life and quality of the wipes. If you still want to make the produced wipes have a fragrant taste, you can add some plant extracts. For example, aloe vera, citrus lemon etc.

Wet wipes can be packaged by selecting a suitable packaging machine according to production requirements. The wet wipes packaging machine can be used to pack a single piece, a pack of 10 pieces, a pack of 20 pieces, a pack of 30 pieces and other specifications.

Fully automatic and semi-automatic wet wipes machine

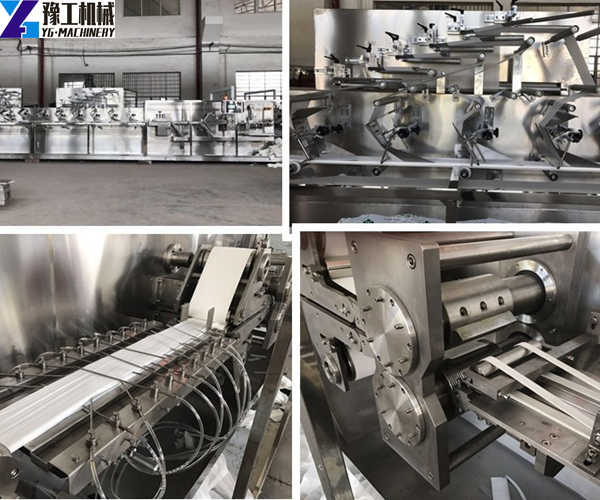

Now, the production of wet wipes relies on mechanized production, which is very efficient. The wet tissue machine can complete a series of processes from raw materials to packaging finished products. Reduced personnel contact, safety and hygiene, and high production efficiency. Wet tissue machines are semi-automatic and fully automatic. The front-end steps and machines of semi-automatic and fully automatic wet tissue machines are the same. That is, feeding, slitting, folding, adding liquid, cutting, stacking, these are all using the same fully automatic device. The packaging, sticking, and boxing of wet wipes can be done with either a fully automatic production line or manual assembly. No matter the degree of automation is high or low, whether it is producing wet wipes in bags or barrels, the selected machine can be purchased according to the production site and needs.

YG- a trusted wet wipes making machine manufacturer

After 18 years of production research and development, the wet wipes machine provided by Yugong has matured. Many overseas customers who cannot come to China for on-site inspection and want to know the production process of the wet wipes machine, the Henan Labor Union provided them with a video of the test machine. Through the test video, customers can see the stability of the finished wet wipes and the actual wet wipes manufacturing process. At present, the wet wipe production machine provided by Yugong can produce almost all wet wipes on the market. Such as barreled wet wipes machine, single-packed wet wipes machine, multi-piece bagged wet wipes machine, individually packaged wet wipes machine and so on. Moreover, Yugong wet wipes machine manufacturers can provide suitable machines according to customer needs, and can provide customized services.