The water canal machine is suitable for all works related to trenching, with excellent performance. It can be used for the paving of cement concrete structures such as gutters, catchments, and crash walls. Therefore, a self-propelled water canal making machine is also called a small canal lining machine. Compared with the traditional artificial lining of canals, the small canal lining machine is fast in construction, and the built canals are smooth and have good performance. The water canal machine provided by YG engineering machinery manufacturer can dig ditches of various shapes such as U-shaped, triangular and rectangular.

Why Use the Water Canal Machine?

When digging water channels, it is usually necessary to manage excavators for leveling and grooving, channel finishing, masonry caulking, pouring the bottom plate, powder edging, building retaining walls, bridging boards, and other processes. Manual laying and construction require a lot of manpower, material resources, and time. It may result in a long construction period and uneven excavation. The self-propelled water canal machine can solve the 4 procedures of trench excavation, which greatly shortens the construction time. In addition, the concrete channel lining machine has the advantages of on-site pouring, uniform lining, and one-time molding. Therefore, most of the time, people use the automatic small canal lining machines to dig canals. If you want to know the details of the device, please leave us a message.

Common Water Canal Making Machine Types

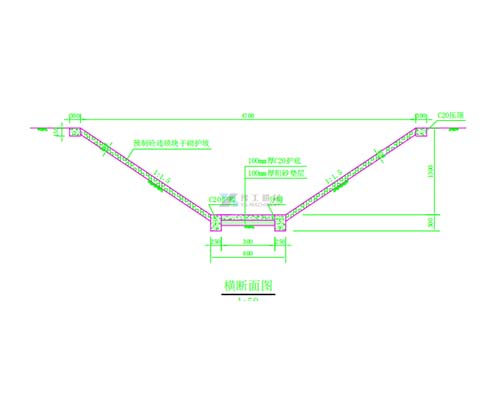

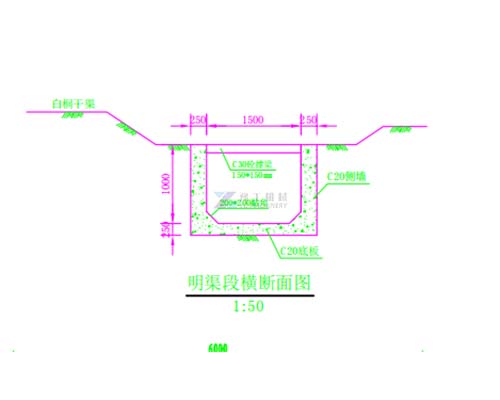

Water channel lining machines support the formation of trenches of various shapes. It supports custom buckets to dig into trapezoidal, rectangular, U-shaped, triangular, V-shaped, L-shaped, and other shapes. Please contact us and send us the shape and exact dimensions of the trench you would like to dig and we will make a plan for you.

Water Canal Forming Process

The canal excavation and forming process roughly includes four steps: trenching, concrete mixing, forming, and post-maintenance.

- Before digging the trench, it is necessary to measure and set out the line according to the location of the trench and the construction site. Measure and lay out the middle and side piles of the canal. Then use the special bucket matched with the trench forming machine to dig out a specific shape with the excavator.

- After the trench is formed, mix the concrete on site.

- Spread the concrete then by using an automatic trench former. After paving, calender the surface of the initial setting channel to improve the water transport capacity and enhance the anti-seepage effect. Then apply finely until achieving a dense, flat, and smooth finish.

- Generally speaking, curing should be carried out 6 to 18 hours after pouring the concrete. The most common maintenance method is to cover the surface of the channel with wet straw curtains, wet reeds, etc.

Self-propelled Water Channel Forming Machine Working Principle

The trench forming machine is driven by hydraulic pressure, and the trench is excavated with a matching bucket. Therefore, the use of a self-propelled small canal lining machine can ensure one-time excavation and molding, eliminating the need for manual repair, and the excavation speed is fast. When the water canal making machine is used to excavate the water trench, the pneumatic electric vibrator propels the concrete in the hopper into the propeller. Start the hydraulic pump station, and the oil cylinder works to push the concrete into the forming mold. The formed concrete is adsorbed on the channel wall corrected by the mechanical blade and extruded at the same time.

Small Canal Lining Machine Structure

As shown in the figure, the concrete channel lining machine includes a hopper, a generator set, a hydraulic pump station, an inner mold, an outer mold, a feeding port, and a stirring motor.

- An electric motor set, agitation motor, and hydraulic pump station power the trench forming machine.

- The hopper stores the mixed concrete.

- Unload the concrete formed by the mold through the unloading port.

Advantages of Self-propelled Water Canal Making Machine

- Fully automatic equipment, avoiding the traditional methods of slow construction, unevenness, waste of raw materials, and other defects.

- According to the size of the trench to be dug, the bucket is customized, the excavation is durable and fast, and the raw materials are saved in the construction.

- The water channel forming machine travels automatically extrudes and vibrates to form, and the repaired canal has good smoothness and good anti-penetration performance.

- With simple operation, it can trim more than 500 meters in one day.

- Strong adaptability. This self-propelled water canal machine is widely used in digging water canals, farmland drainage canals, slope sliding films, etc.

- The trimmed channel is flat and smooth, which is convenient for later maintenance.

Machine Recommendation

YG engineering machine manufacturer also supplies road construction machines, rebar processing machines, concrete cutting machines, paper packing machines, and plastic processing machines. Such as pile breaker machines, paper bowl machines, paper tube making machines, disposable paper cup machines, mortar spraying machines, automatic wall plastering machines, water well drilling machines, and others. If you are looking for the machine, please leave us a message.