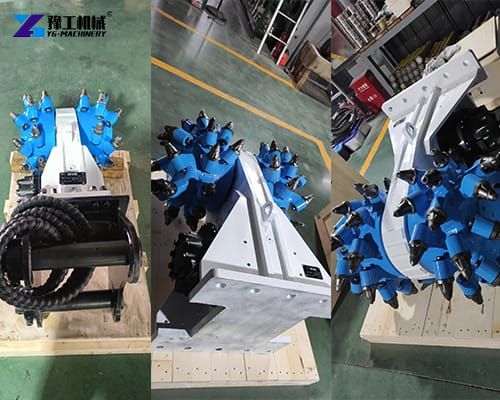

Rotary drum cutter, also known as a rock grinder, rock drum cutter, or hydraulic milling machine, is a specialized excavator attachment. It features a rotating drum equipped with multiple cutting teeth or picks. As the drum rotates, the teeth engage with the material, breaking it down into smaller pieces for easy removal. This method of excavation is highly effective, offering precise control and minimal disturbance to the surrounding environment. It is powered by the excavator’s hydraulic system and can efficiently grind, mill, and cut through a wide range of materials.

Parameters of the Rotary Drum Cutter

| Product Model | HX-X1 | HX-X2 | HX-Z1 | HX-Z2 | HX-D |

| Applicable Models | 6-9T | 10-18T | 20-27T | 30-40T | 45-60T |

| Machine Weight | 450kg | 550kg | 1100kg | 1250kg | 2450kg |

| Milling Width | 420mm | 650mm | 850mm | 950mm | 1150mm |

| Milling Head Diameter | 340mm | 450mm | 560mm | 660mm | 850mm |

| Number of Blade Heads | 40 | 56 | 64 | 64 | 60 |

| Recommended Speed | 95r/min | 85r/min | 78r/min | 75r/min | 55r/min |

| Recommended Flow Rate | 80L/min | 120L/min | 220L/min | 320L/min | 360L/min |

| Maximum Pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Maximum Torque | 4700NM | 7000NM | 14300NM | 23300NM | 40300NM |

Rotary Drum Cutter Features

- Precision Cutting: Dual hydraulic motors drive powerful drums equipped with wear-resistant picks for efficient material removal.

- Low Noise & Vibration: Ideal for sensitive urban and residential job sites.

- Versatile Applications: Suitable for trenching, tunneling, wall profiling, underwater work, and demolition.

- Durable Build: High-grade steel housing and carbide-tipped cutting teeth ensure long-lasting performance.

Applications of Excavator Drum Cutter

- Trenching for Pipelines and Cables

Rotary drum cutters excel at creating narrow, deep trenches for the installation of pipelines, cables, and other utilities, ensuring minimal disruption to the surrounding area. - Foundation Excavation

For building foundations, it provides the precision needed to excavate to exact specifications, ensuring a stable and level base. - Tunneling and Mining

In tunneling and mining operations, hydraulic drum cutter is used to bore through rock and soil, facilitating the creation of tunnels and shafts with minimal environmental impact. - Demolition and Site Preparation

Rotary drum cutters can also be employed in demolition projects to break down concrete and other hard materials, as well as in site preparation tasks such as clearing land for construction.

Benefits of Using Hydraulic Drum Cutter

- Precision Excavation

Excavator drum cutters allow for highly accurate trenching and excavation, making them ideal for projects requiring tight tolerances, such as pipeline installation or foundation work. - Versatility

Capable of handling a variety of materials, including soft soil, clay, shale, and even hard rock, rotary drum cutters are adaptable to diverse project requirements. - Reduced Vibration and Noise

Compared to traditional excavation methods, hydraulic drum cutters produce significantly less vibration and noise, minimizing disruption to nearby structures and communities.