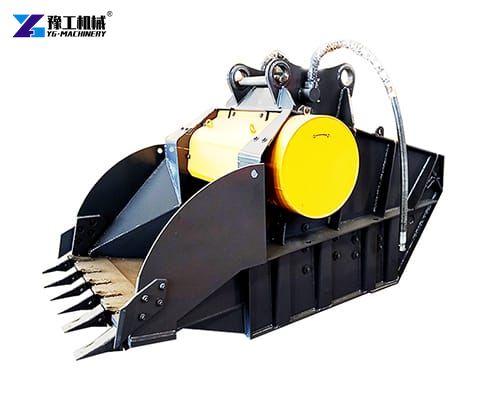

Excavator crusher bucket is a specialized attachment designed to be mounted on hydraulic excavators. Its primary function is to crush and recycle materials such as concrete, asphalt, stone, and demolition waste directly at the job site. The crusher bucket operates using the hydraulic system of the host excavator. It features robust jaws or rotors equipped with hardened steel teeth that apply immense pressure to break materials into smaller, manageable pieces. The crushed output can be adjusted to specific sizes, making it suitable for reuse or disposal in construction projects.

Parameters of the Excavator Crusher Bucket

| Model | YGDP-25 | YGDP-35 | YGDP-45 | YGDP-55 | YGDP-65 |

| Suitable Excavator | 20-25T | 24-35T | 30-40T | 35-50T | 45-70T |

| Working Pressure | 25MPa | 25MPa | 25MPa | 25MPa | 25MPa |

| Recommended Flow Rate | 180L/min | 220L/min | 260L/min | 300L/min | 390L/min |

| Weight | 2900KG | 3950KG | 4850KG | 5800KG | 6900KG |

| Volumetric Capacity | 0.7m³ | 0.9m³ | 1.05m³ | 1.2m³ | 1.4m³ |

| Crushing Size | 15-130mm | 15-130mm | 15-130mm | 15-140mm | 15-160mm |

| Jaw Width | 750mm | 900mm | 1100mm | 1300mm | 1500mm |

| Jaw Height | 400mm | 400mm | 450mm | 450mm | 450mm |

Components and How It Work

The effectiveness of an excavator crusher bucket lies in its robust design and the synergy of its components, powered by the excavator’s hydraulic system.

- The Bucket Structure: Constructed from high-strength, wear-resistant steel, the bucket body forms the housing for the crushing mechanism and the chamber where material is processed. Its durability is essential to withstand the immense forces generated during crushing and the abrasive nature of the materials being processed.

- The Jaw Plates: These are the primary working parts responsible for crushing. Typically made from manganese steel or other hardened alloys, they consist of a fixed jaw plate and a movable jaw plate. The movable jaw plate, driven by the hydraulic system, oscillates against the fixed plate, progressively crushing the material fed between them. The profile of the jaw plates is designed to optimize the crushing action and grip the material effectively.

- The Hydraulic System: The excavator’s hydraulic power is the engine of the crusher bucket. Hoses connect from the excavator’s auxiliary hydraulic circuits to the bucket’s hydraulic motor or cylinder. This power actuates the mechanism that drives the movable jaw plate, providing the force and movement required for crushing.

Benefits of Using an Excavator Crusher Bucket

Investing in a bucket crusher for an excavator offers numerous advantages for construction and demolition firms:

- Cost Efficiency

Reduced Transportation Costs: By crushing materials on-site, companies eliminate the need to transport debris to off-site crushers or landfills.

Reusable Materials: Crushed aggregates can be repurposed as base layers for roads, fill material, or concrete mix, reducing the need to purchase new materials. - Versatility

Multi-Material Capability: From concrete and asphalt to natural rock, crusher buckets handle diverse materials with ease.

Adaptability to Job Sites: Their compact size allows operation in tight spaces, such as urban areas or narrow trenches. - Increased Productivity

Speed: Crushing and processing occur in real-time, accelerating project timelines.

Simplified Workflow: The integration of crushing and excavation into one machine reduces equipment downtime.

Applications of Excavator Rock Crusher Bucket

The versatility of excavator crusher bucket makes them indispensable across various industries:

- Construction and Demolition

Building Demolition: Crush concrete, bricks, and rebar-laden debris into reusable aggregates.

Site Preparation: Process rock and soil to create stable foundations. - Road and Infrastructure Projects

Recycling Asphalt: Crush old pavement into base material for new roads.

Utility Trenching: Break through rock and concrete to install pipelines or cables. - Mining and Quarrying

Rock Crushing: Reduce oversized boulders to manageable sizes for further processing.

Aggregate Production: Create consistent gradations of material for construction use. - Landscaping and Urban Development

Terrain Shaping: Crush rock for pathways, driveways, or decorative landscaping.

Historic Preservation: Selective demolition in areas with architectural constraints.