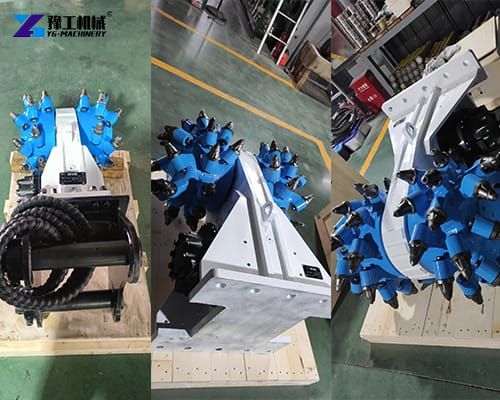

Drum cutter attachment for excavator is a specialized tool mounted on the arm of an excavator. It consists of a rotating drum equipped with multiple cutting tools or teeth. As the drum rotates, these teeth engage with the material, breaking it down into smaller pieces. It uses rotating drums equipped with cutter picks to grind through rock, concrete, or asphalt. Different from traditional excavation tools, drum cutters provide low vibration, controlled cutting, and excellent precision, making them ideal for urban construction, tunneling, demolition, and pipeline trenching.

Parameter of the Drum Cutter Attachment

| Product Model | HX-X1 | HX-X2 | HX-Z1 | HX-Z2 | HX-D |

| Applicable Models | 6-9T | 10-18T | 20-27T | 30-40T | 45-60T |

| Machine Weight | 450kg | 550kg | 1100kg | 1250kg | 2450kg |

| Milling Width | 420mm | 650mm | 850mm | 950mm | 1150mm |

| Milling Head Diameter | 340mm | 450mm | 560mm | 660mm | 850mm |

| Number of Blade Heads | 40 | 56 | 64 | 64 | 60 |

| Recommended Speed | 95r/min | 85r/min | 78r/min | 75r/min | 55r/min |

| Recommended Flow Rate | 80L/min | 120L/min | 220L/min | 320L/min | 360L/min |

| Maximum Pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Maximum Torque | 4700NM | 7000NM | 14300NM | 23300NM | 40300NM |

Advantages of the Excavator Drum Cutter Attachment

- Good Cutting Power: Drum cutter attachment for excavator can handle the toughest materials – granite, basalt, reinforced concrete, asphalt, frozen ground.

- Precision & Control: Allows operators to make precise cuts, trenches, profiles, and controlled demolition with minimal collateral damage.

- Reduced Vibration & Noise: Significantly quieter and less vibratory than jackhammers or hydraulic breakers, improving operator comfort and site safety.

- Versatility: One attachment for multiple tasks: demolition, trenching, rock excavation, surface leveling, concrete reduction, channeling.

- Cost-Effective: Higher productivity rates, lower maintenance costs vs. constant hammer bit/consumable replacement, reduced labor needs.

Wide Application of Drum Cutter Attachment for Excavator

- Rock Excavation: Ideal for soft to medium-hard rock, drum cutters can precisely cut through challenging surfaces without the need for blasting.

- Trenching: Create narrow, deep trenches for utilities, pipelines, and foundations with minimal disruption to the surrounding area.

- Tunneling: Perfect for creating smooth, even walls and ceilings in tunneling projects.

- Demolition: Safely and efficiently break down concrete structures and other hard materials.

Choosing the Right Drum Cutter Attachment

Selecting the appropriate drum cutter attachment for excavator involves considering several factors:

- Excavator Size and Power

Ensure that the drum cutter attachment is compatible with your excavator’s size and hydraulic power. An attachment that is too large or too powerful can strain your excavator’s hydraulic system, while an undersized attachment may not deliver the desired performance. - Material Type

Different drum cutters are designed to handle specific materials, such as soft rock, hard rock, or concrete. Choose an attachment with cutting tools that are suitable for the materials you will be working with. - Cutting Width and Depth

Consider the required cutting width and depth for your project. Excavator drum cutters come in various sizes, allowing you to select an attachment that meets your specific needs.