Concrete laser leveling machine is a specialized piece of equipment designed to automate the process of placing, spreading, and finishing concrete slabs. Different traditional methods that rely on manual labor or semi-automated tools, this machine integrates laser-guided technology to achieve a perfectly level surface. The system comprises three primary components: laser transmitter, laser receiver, and hydraulic or mechanical screed. By synchronizing these elements, the machine ensures that the concrete surface adheres to precise grade specifications, eliminating human error and significantly reducing labor-intensive tasks.

Parameters of the Concrete Laser Leveling Machine

| Model | YG-CL300 |

| Engine model | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) |

| Engine type | Gasoline, air-cooled 4-stroke, twin-cylinder engine |

| Engine power | 22KW/30ps |

| Fuel capacity | 20L (operation time is about 8 hours |

| Hydraulic oil capacity | 37L |

| Laser transmitter | Swiss Leica/Tower transmitter (optional) |

| Laser receiver | Swiss Leica/Tower receiver (optional) |

| Laser system control effect | Plane, slope, double slope (three-dimensional) |

| Laser system control method | Microcomputer laser scanning |

| Paving method | Hydraulic stirring cage paving |

| Vibration method/excitation force | Hydraulic vibration/2000N |

| Vibration plate width | 2500mm |

| Leveling thickness | 50-300mm |

| Travel drive | Reducer motor integrated |

| Travel speed | 0-4Km/h (speed adjustable) |

| Travel tire | Solid anti-skid and anti-puncture tires (optional wide tires) |

| Body size | 3250x2850x1320mm |

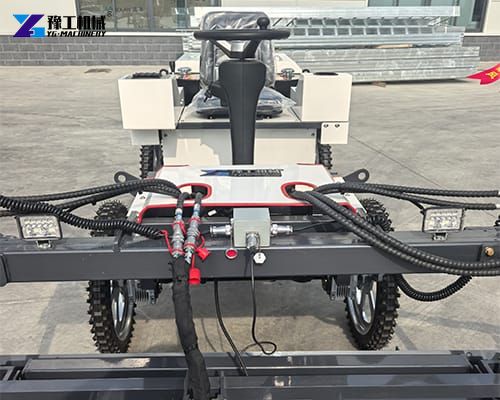

Components of the Concrete Laser Leveling Machine

- Laser Transmitter: Mounted on a tripod, this device emits a rotating laser beam to create a reference plane across the work area.

- Laser Receiver: Attached to the leveling machine, it detects the laser beam and communicates with the machine’s control system to adjust the blade height in real time.

- Hydraulic or Mechanical Screed: This component spreads the concrete while maintaining the desired elevation based on laser feedback.

Wide Applications of Laser Leveling Machine

Concrete laser leveling machines have become indispensable in a wide range of sectors:

- Industrial Flooring

Factories, logistics centers, and manufacturing plants require flawless floors to support heavy machinery and forklift traffic. Laser leveling ensures durability and minimizes maintenance. - Commercial Construction

Shopping malls, parking garages, and office buildings benefit from aesthetically pleasing, level surfaces that meet strict architectural standards. - Road and Highway Projects

Laser-guided machines create smooth, sloped surfaces for roads, bridges, and runways, enhancing drainage and safety. - Agricultural Facilities

Dairy farms, feedlots, and storage facilities use these machines to create impermeable, easy-to-clean floors that resist bacterial growth. - Residential Construction

Homebuilders leverage laser leveling for driveways, patios, and garage floors, delivering professional-grade finishes without the premium cost.

How Does A Concrete Floor Leveling Machine Work?

The operation of a concrete laser leveling machine can be broken down into four stages:

- Site Preparation

Before the machine is deployed, the construction site must be prepared. This includes setting up the subgrade, installing formwork, and positioning the laser transmitter. The transmitter’s elevation is calibrated to match the project’s design specifications, creating a reference plane for the entire slab. - Concrete Placement

Fresh concrete is poured onto the prepared subgrade in bulk. The laser concrete leveling machine is then driven over the wet concrete. Depending on the model, the machine may be rider-operated or fully automated. - Real-Time Adjustments

As the machine moves, the laser receiver continuously monitors its position relative to the reference plane. If deviations are detected, the system automatically adjusts the screed’s height to ensure consistent thickness and slope. This real-time correction guarantees a flat, even surface without dips or ridges. - Finishing

Once the concrete is leveled, additional attachments or manual tools can be used for final finishing, such as troweling or adding surface textures. The result is a slab that meets exact tolerances.

Advantages of Using a Laser Concrete Leveling Machine

The adoption of laser leveling machines offers numerous benefits for contractors, engineers, and project owners:

- High Precision

Traditional methods like hand screeding or mechanical vibratory screeds struggle to achieve the precision of laser-guided systems. By eliminating human error and relying on real-time data, these machines produce surfaces with minimal deviation, critical for applications like industrial floors or airport runways. - Increased Efficiency

A single concrete laser leveling machine can replace dozens of workers, drastically reducing labor costs and project timelines. For large-scale projects, such as warehouse floors or highway pavements, this efficiency translates into faster completion and earlier return on investment. - Enhanced Durability

Properly leveled concrete slabs are less prone to cracking, uneven wear, or water pooling. By ensuring uniform density and thickness, laser-leveled concrete enhances structural integrity and longevity, reducing maintenance costs over time.