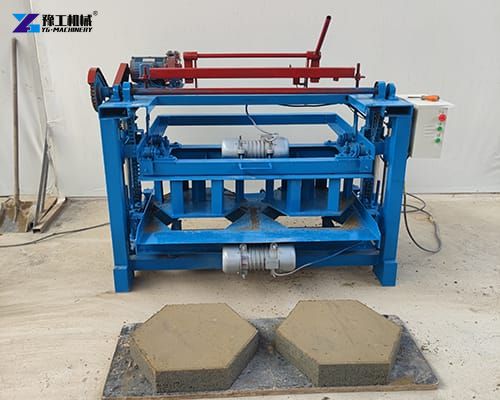

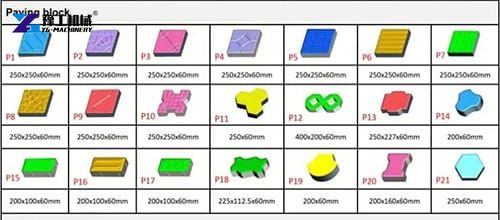

As an indispensable equipment in the modern construction industry, the block brick making machine was exported to France last week. It is widely used in the production of block bricks for various construction projects. The main function is to make various specifications of block bricks by scientific proportion and high-pressure molding of raw materials such as cement, sand, gravel, and lime to meet the needs of construction. There are various shapes of blocks available, people can choose the suitable one based on their real needs.

Parameter of the Block Brick Making Machine

| Molding Cycle(s) | 45s |

| Power(kW) | 4.5kw |

| Daily production(block) | 400*200*200MM 3200 400*150*200MM 3840 400*100*200MM 5760 240*115*53MM 12600 |

| Machine size(mm) | 1250*1350*1550 |

| Machine weight(kg) | 750 |

| Number of operators | 2-3 |

Application of the Brick Making Machine

Block brick making machine exported to France can produce various types of block bricks, including wall bricks, partition bricks, load-bearing bricks and various decorative bricks, which are widely used in such as residential, commercial buildings, roads, bridges, and other engineering projects, etc. And we can customize the machine based on your requirements.

Block Brick Making Machine Advantages

- Improve production efficiency: The block brick making machine greatly improves production efficiency through automatic production processes, and can quickly meet large-scale construction needs.

- Reduce labor costs: The use of mechanized equipment reduces the need for human resources and greatly reduces labor costs, thereby saving money for construction projects.

- Stable quality: The block bricks produced by the machine are strictly controlled in the raw material ratio and molding process, which can ensure stable product quality and reduce the production of unqualified bricks, meeting the diversified and high-standard requirements of modern buildings.