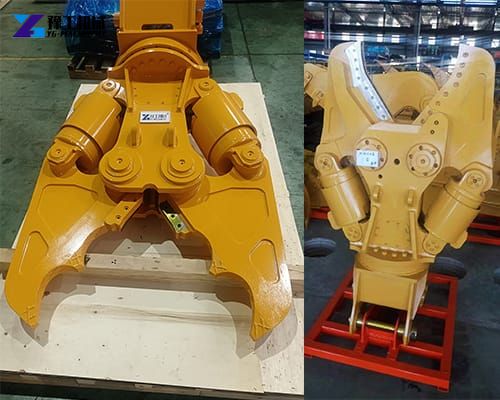

Metal shear for excavator is a specialized hydraulic attachment that is designed to be mounted on the arm of an excavator. Once attached, it transforms the excavator into a powerful cutting machine, capable of slicing through a wide range of materials with ease. These materials include thick metal beams, steel plates, and rebars. It is commonly used in demolition projects, scrapyards, and industrial dismantling operations. The shear’s design is centered around a hydraulic system, which provides the necessary force to close the jaws of the shear, creating a powerful cutting action. This hydraulic power is what makes hydraulic shears for excavators so effective in handling tough materials.

Specifications of the Double Cylinder Metal Shear for Excavator

| Model | YGD280 | YGD380 | YGD480 |

| Suitable Excavator | 22-27T | 28-36T | 37-45T |

| Weight | 2650KG | 3850KG | 4540KG |

| Blade Length | 400+260mm | 350+360mm | 350+360mm |

| Working Pressure | 320bar | 330bar | 330bar |

| Length | 2380mm | 2700mm | 3655mm |

| Opening | 855mm | 780mm | 780mm |

| Cut Depth | 685mm | 650mm | 650mm |

| Shear Force | 1360KN | 2940KN | 2940KN |

Main Advantages of Excavator Shear Attachment

- High Cutting Efficiency: The metal shear for excavator is designed for rapid operation, reducing downtime and improving throughput.

- Durable Construction: Engineered with wear-resistant materials to handle high-impact use without frequent maintenance.

- 360-Degree Rotation: Optional rotation allows for precise positioning and versatile use on site.

- Easy Installation: Compatible with a wide range of excavator models and quick couplers.

Applications Where YG’s Excavator Shears

The versatility of a high-quality metal shear for excavator makes it indispensable across numerous sectors:

- Scrap Yards & Recycling Centers: Primary shearing of automobiles, appliances, structural steel, and mixed metals.

- Industrial Demolition: Dismantling structures, processing beams, columns, tanks, and machinery on-site.

- Infrastructure Decommissioning: Cutting pipelines, processing bridge components, and handling railway scrap.

- Disaster Recovery: Rapidly clearing and processing metal debris after natural disasters or accidents.

Why Choose A Metal Shear for Excavator?

- Enhanced Safety

Safety is a top priority in any construction or demolition project. The use of an excavator metal shear significantly improves safety conditions. With an excavator shear, the operator can maintain a safe distance from the cutting area, reducing these risks. - Increased Efficiency

Excavator metal shears are designed to work quickly and efficiently. The powerful hydraulic system enables the shear to make rapid cuts through thick materials. This means that projects can be completed in a shorter time frame. - Versatility

The excavator metal shear is a highly versatile tool. It can be used to cut through a variety of materials, including different types of metals, wood, and, in some cases, concrete.

How to Choose the Right Metal Shear for an Excavator?

Selecting the right metal shear for an excavator requires careful consideration of several factors.

- Excavator compatibility is the first step. The shear must match the excavator in terms of weight, hydraulic flow, and pressure requirements to ensure safe and efficient operation.

- Next, consider the type of work to be performed. Demolition projects involving thick structural steel may require a heavy duty shear with high cutting force, while recycling operations may prioritize speed and rotation capability.

- Jaw opening size and blade length should also be evaluated, as they determine the maximum material size the shear can handle. Additionally, ease of maintenance and availability of spare parts are important factors that influence long term ownership costs.