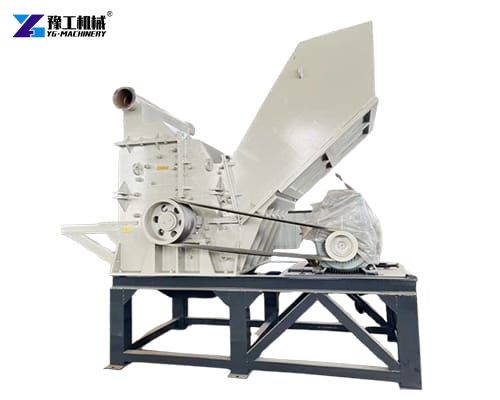

Metal recycling shredder, also known as a scrap metal shredder or industrial metal shredder, is a heavy-duty machine designed to tear apart the size of various types of metal scrap for easier handling, transportation, and further recycling. Utilizing powerful rotating shafts with durable cutters or hammers, these shredders effectively break down materials that would otherwise be difficult or impossible to handle. Whether you are processing steel drums, aluminum sheets, copper wires, or ferrous and non-ferrous metals, an industrial metal shredder boosts operational efficiency while reducing labor and transport costs.

Features of Metal Recycling Shredder

- High-Capacity Processing

Scrap metal shredders are engineered to handle vast quantities of scrap metal, from automobiles and appliances to industrial machinery and construction debris. Their robust construction and powerful motors enable continuous operation, ensuring maximum throughput and productivity. - Versatile Shredding Capabilities

These shredders are not limited to a single type of metal. They can effectively process ferrous metals (like iron and steel) as well as non-ferrous metals (such as aluminum, copper, and brass). This versatility makes them indispensable in comprehensive recycling operations. - Customizable Shredding Sizes

Depending on the specific requirements of your recycling process, the industrial metal shredder can be adjusted to produce different fragment sizes. This flexibility allows for optimal sorting and downstream processing, enhancing the overall efficiency of your recycling facility. - Durable Construction

Built to withstand the rigors of heavy-duty use, metal recycling shredders feature high-quality materials and precision engineering. Their robust design ensures longevity, reducing maintenance costs and downtime.

Applications of Industrial Scrap Metal Shredders

- Automotive Recycling

In the automotive recycling industry, shredders are used to break down end-of-life vehicles into smaller pieces, facilitating the separation of different materials for recycling. - Appliance Recycling

Household appliances, such as refrigerators, washing machines, and air conditioners, contain valuable metals that can be recovered through shredding. This process helps divert these items from landfills and promotes resource conservation. - Construction and Demolition Waste

During construction and demolition projects, large amounts of metal debris are generated. Metal recycling shredders can efficiently process this waste, recovering reusable metals and reducing the environmental impact of construction activities.

Why Shredding is Essential for Modern Metal Recycling?

Volume Reduction: Dramatically decreases the bulk of scrap, slashing transportation and storage costs.

Liberation of Materials: Breaks apart composite items (like cars), separating ferrous metals, non-ferrous metals (copper, aluminum), and non-metallics (plastic, rubber) for easier downstream sorting.

Increased Material Value: Produces clean, dense shred ideal for steel mills and foundries, commanding higher prices than unprepared scrap.

Improved Processing Efficiency: Small, uniform fragments flow smoothly through sorting systems (magnets, eddy currents, screens) and melt faster in furnaces.

Choosing the Right Recycling Shredder for Metal

When selecting a metal recycling shredder for your facility, consider the following factors:

Capacity Requirements: Determine the volume of scrap metal you need to process daily to choose a shredder with the appropriate throughput.

Material Type: Ensure the shredder is capable of handling the types of metals you plan to recycle, including any specific alloys or contaminants.

Space Constraints: Consider the available space in your facility and choose a shredder that fits comfortably without compromising operational efficiency.