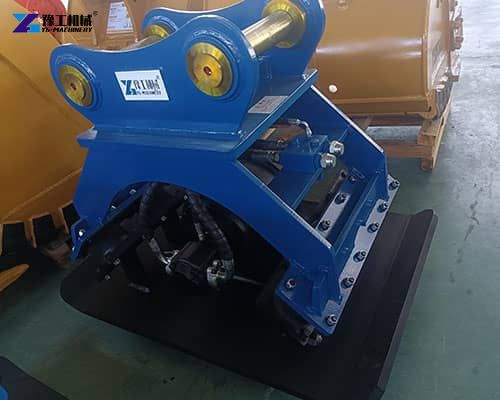

Hydraulic plate compactor is a special compaction tool, that compacts various terrain parts through high-frequency vibration. As an excavator attachment, it adopts a hydraulic motor, shock-absorbing rubber block, and wear-resistant material tamping plate, which not only ensure the service life but also improve the construction efficiency and save labor costs. The equipment is suitable for the compaction of ditches, slopes, steps, complex terrain, pile driving crushing, etc.

Features of the Hydraulic Plate Compactor

- Use manganese plate steel, which is high-strength and corrosion-resistant

- The pin shaft is made of alloy steel, with a built-in oil channel, high in strength and good toughness

- Adopt a hydraulic vibration motor, which is strong and durable

- The bearing has low noise, safe and reliable

- The shock absorber has good toughness and fatigue resistance

Application of the Hydraulic Vibration Compactor

Hydraulic plate compactor can be used directly for piling pile driving and crushing after installing the fixture. It is mainly used for the compaction of highway and railway roadbeds such as the back of abutments, culvert sides, corners, shoulders, and slope protection, the compaction of embankments and their slope protection, the compaction of building trenches and backfill soil, the compaction of concrete pavement repairs, and the compaction of municipal side ditches, wellheads, and pipe sides.

Attention and Maintenance

- Cleaning and maintenance: After each use, the dirt and other debris on the surface of the compactor should be cleaned in time.

- Check the lubricating oil: Check the lubricating oil of the compactor regularly to keep it in good working condition.

- Bolt inspection: Check the bolts and connectors on the hydraulic plate compactor regularly to ensure that they are safe and reliable.

- Check all parts of the compactor regularly to see if they are intact. If they are damaged or worn, they should be replaced in time.

- When the compactor is not used for a long time, it should be stored in a dry, ventilated environment without corrosive gases.