Egg tray production machine is a pulp molding equipment, which uses waste book paper, waste newspaper, waste cardboard, waste scraps from printing and packaging plants, and tailings from paper mills as raw materials to produce various degradable egg trays. In addition to making egg trays, it can also make coffee cup trays, fruit trays, and paper trays for inner packaging of electronic products. It mainly goes through the processing steps of beating, molding, dehydration, drying, etc.

Parameter of the YG Egg Tray Making Machine

| Model | YG-1000-3X1 | YG-1500-4X1 | YG-2500-3X4 | YG-3000-4X4 | YG-4000-4X8 | YG-5000-5X8 | YG-7000-6X8 |

| Capacity/hour | 1000pcs/h | 1500pcs/h | 2500pc/h | 3000pcs/h | 4000pcs/h | 5000pcs/h | 7000pcs/h |

| Power/hour | 38kw | 38kw | 55kw | 60kw | 95kw | 95kw | 120kw |

| Voltage | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz |

| Weight | 2500kg | 3000kg | 4000kg | 4800kg | 7000kg | 8000kg | 10000kg |

| Dimensions (main machine) | 2600*2200*1900mm | 2800*2200*1900mm | 2900*1800*1800mm | 3250*1800*1800mm | 3250*2300*2500mm | 3700*2300*2500mm | 3200*2300*2500mm |

| Paper consumption/hour | 80kg | 120kg | 200kg | 240kg | 320kg | 400kg | 480kg |

| Water consumption/hour | 160kg | 240kg | 400kg | 480kg | 640kg | 800kg | 960kg |

| Drying | Dry naturally | Dry naturally | Multi-layer drying | Multi-layer drying | Multi-layer drying | Multi-layer drying | Multi-layer drying |

Applicable Scope of the Pulp Molding Equipment

Parts of Egg Tray Production Machine

The egg tray machine mainly includes pulping, molding, and drying systems.

- Pulping system: Waste paper such as old newspapers, magazines, and cartons is crushed, screened, and dyed to form the paper pulp for molding. The main egg tray production machine includes a hydraulic pulper, agitator, pulp pump, water pump, control cabinet, etc. According to different requirements for the finished product, adding thick pulp and fine pulp equipment, such as a vibrating screen, pulping machine, etc is appropriate.

- Molding system: The pulp is evenly attached to a special molding mold through the vacuum to form a wet blank product, which is then transferred to the drying system or dried naturally.

- Drying system: After pulping and molding, pulp products generally contain a high moisture content and need to be dried to remove the moisture in the product. The main drying methods include natural drying, drying boxes, metal multi-layer drying, civil engineering drying, and so on. Customers can choose the suitable type according to their own factory size, energy conditions, and actual needs.

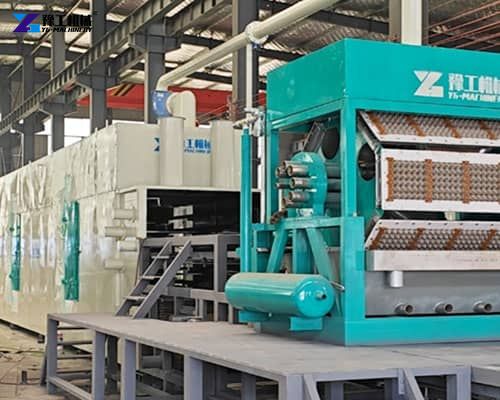

YG-Multilayer Metal Drying Equipment for Shaped Egg Trays

- This egg tray production machine is a professional supporting paper egg tray production of drying equipment, the transport mode is 6 layers of hanging transport, effectively increasing the drying distance, and reducing the floor area, the heat source of this equipment can choose coal, biomass particles, natural gas, diesel, etc., compared with the traditional brick kiln drying advantages: reduce the cost of heat source more than 20%, occupy a small area, can be moved, using PLC automatic control, and modeling atmosphere, easy installation, easy maintenance.

- This egg tray manufacturing machine is mainly used for the production of more than 3000 pieces of models, the internal and external panels and hanging plates are made of galvanized material, and the whole is made of rock wool insulation board insulation, with eddy current induced draft fan and domestic well-known brand burning machine, the chain uses GB/T8350 conveyor chain, the equipment structure is reasonable, mature technology, has been tested by the long-term market.