With the development of urban infrastructure, the use of steel bars has gradually increased. When new buildings are built, old buildings must be demolished. During the demolition of old buildings, many waste steel bars are produced. Scrap steel bars can be cut into pellets using a steel bar cutter, and then sent to steel mills for recycling. Yugong’s iron rod cutting machine is very popular in many countries, such as Malaysia, Pakistan, Kenya, and others countries. Why are steel bar-cutting machines popular in these countries? How does it cut the rebar? The following is an introduction to you.

Why are steel bar cutting machines popular?

In order to build a more beautiful city, old buildings are demolished, and new buildings are built all over the world. A large amount of waste steel bars will be produced at the demolition construction site. These waste steel bars can be turned into treasures. These demolished rebars can be transported to steel mills for refurbishment. And long steel bars are inconvenient to transport. Therefore, it is necessary to use a steel bar-cutting machine that can cut steel bars into segments. Processed steel bars are the favorite raw materials of all steel mills today. And figures released from steel mills show that processed rebar segments are being offered at higher prices than unprocessed rebar. Moreover, the amount of steel bars on the construction site is also very large, and the profits obtained from recycling and reselling the waste steel bars in one day are also very considerable.

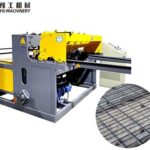

Introduction of Steel Bar Cutting Machine

The steel bar cutting machine is a special equipment for processing waste steel bars, especially short-end steel bars. It can cut a short section of rebar into pellets. At present, the steel bar cutting machine is mainly used for the processing of steel bar waste before returning to the furnace. The steel bar cutter can be used to cut steel bars with a diameter of 6~32mm. It can cut round steel, and rebar, and also cut small flat steel, angle steel, square steel, square tube, and other profiles. The steel bar cutting machine adopts double heads to cut material at the same time, which speeds up the cutting speed of the steel bar and greatly improves the production efficiency. The feeding system has high fault tolerance and can also handle slightly bent steel bars.

Steel Bar Cutting Machine Price in Malaysia

Malaysia is an important steel producer and exporter in Southeast Asia. The steel industry is an important basic industry in Malaysia. Since the beginning of the 21st century, Malaysia has launched a number of economic development plans, and the overall demand for steel has been increasing. Yugong has exported several steel bar-cutting machines to Malaysia. This rebar cutter is available in various models. And it can be cut in many sizes. If you want to know the steel bar cutting machine price in Malaysia, please contact us. We will recommend the right machine for you according to your needs.

Related Rebar Processing Machinery?

When processing steel bars, we may need to process steel bars into various shapes and sizes, requiring different equipment. YG provides a variety of rebar processing equipment for sale to meet the different needs of customers. For example, steel bar straightening machines, steel bar straightening and cutting machines, I-beam cold bending machines, straight thread rolling machines, steel bar upsetting machines, arc punching machines, and other steel bar equipment. If you are looking for rebar equipment for your project, please leave us a message.