Paper Cup Making Machine Factory Price

The automatic paper cup making machine is designed to make PE-coated paper cups. The paper cup can hold cold and hot drinking cups, tea cups, coffee cups, ice cream cups as well as food containers. This disposable cup manufacturing equipment is also called paper glass making machinery, coffee paper cup machine, and paper tea cup forming machine. In addition, we have the paper cup printing machinery, and roll die cutting equipment for customers to choose from. Contact us to get the paper cup-making machine price now.

Disposable Paper Cup Machine Model

1: High-Speed Paper Cup Making Machine SMD-90 90-100 cups/min

2: Double Wall Paper Cup Making Machine SMD-80A 70 cups/min

3: Middle-Speed Paper Bowl Making Machine SMD-70B 70-80 cups/min

4: Middle-Speed Paper Glass Making Machine SMD-60 60-70 cups/min

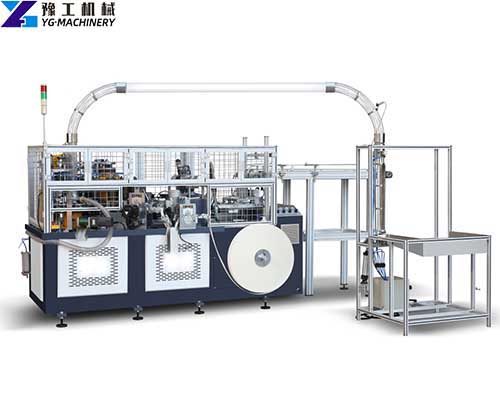

SMD-90 High-Speed Paper Coffee Cup Making Machine

| Model | SMD-90 |

| Cup Size | Top Diamerter:60mm-115mm Bottom Diameter:50mm-85mm Height:65mm-180mm |

| Rated Speed | 90-100cups/min |

| Total Power | 380V,50Hz |

| Power Installed | 12KW |

| Air Source | 0.4m³/min;0.5MPa customer-owned |

| Applicable Base Paper | 190-350g(single or double PE coating paper) |

| Weight | 3400KG |

| Main Size | 2500*1800*2700mm |

| Paper Cup Collector Size | 900*900*1760mm |

| Actual Power Consumption | 7.5KW |

| Remark | The paper thickness error margin±0.05mm for the same set of mold |

SMD-80A Double Wall Paper Cup Making Machine

| Model | SMD-80A |

| Specification of Paper Cup | 6-22 ounce |

| Paper Material | 135-450g/㎡ |

| Speed | 70-80pcs/min |

| Total Power | 380V.50Hz,10KW |

| Air Consumption | 0.5m³/min |

| Weight | 3000KG |

| Machine Dimension | 2500*1800*1700mm |

SMD-70B Middle-Speed Disposable Cup Making Machine

| Model | SMD-70B |

| Specification of Paper Cup | 6-22 ounce |

| Bowl Size Range | Top Diamerter:90mm-150mm Bottom Diameter:60mm-115mm Height:50mm-135mm |

| Paper Material | 135-450g/㎡ |

| Speed | 60-70pcs/min |

| Total Power | 380V.50Hz,14KW |

| Air Consumption | 0.5m³/min |

| Weight | 3400KG |

| Machine Dimension | 2500*1800*1700mm |

SMD-60 Middle-Speed Paper Glass Making Machine

| Model | SMD-60 |

| Specification of Paper Cup | 6-22 ounce |

| Paper Material | 160-380g/㎡ |

| Speed | 60-70pcs/min |

| Total Power | 380V.50Hz,9KW |

| Air Consumption | 0.4m³/min |

| Weight | 2200KG |

| Machine Dimension | 2700*1600*1300mm |

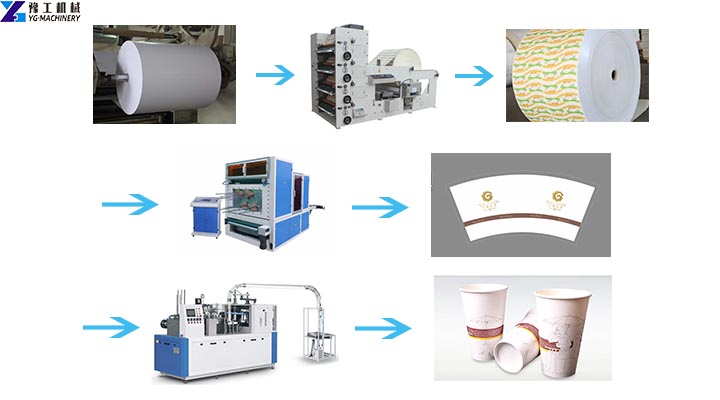

Paper Cup Production Process

The paper cup production process mainly includes coated paper-printing-die-cutting-forming and other processes.

- Buy Coated paper. Before using the paper cup machine to make paper cups, customers need to purchase coated paper. There is single-coated paper (for making ordinary cups and hot drink cups) and double PE-coated paper (for making cold drink cups).

- Printing. Draw the plan of the cup according to the sample cup and parameters, and use the printing machine to print after typesetting.

- Die cutting. Die-cut the printed web into fan-shaped pieces.

- Molding. Put the sector pieces on the disposable cup making machine for forming. Different models of paper cup machines can make paper cups of different specifications.

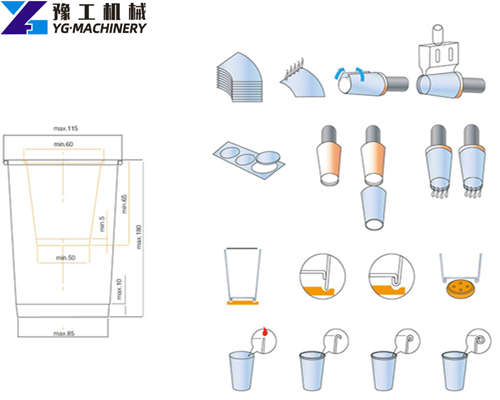

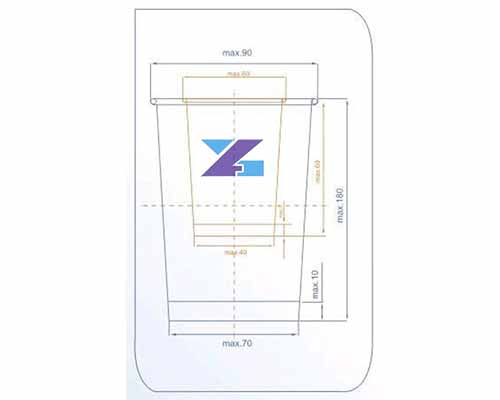

How to Confirm the Cup Size?

Paper cup sizes have many details to pay attention to. Different sizes will have different links. For example, cup bottom depth and cup angle will affect the cup stack while rim curling dimension and top diameter will affect the lid fit of cups, etc. The most important factor is how the market will accept your cup size. After you know about the market demand, we will require you provides your paper cup size drawing or samples. Our designer will measure and offer you official drawings. Forming mold design will be started upon your confirmation. Contact us if you’re looking for paper cup manufacturing machine suppliers.

How to Select Paper?

Mostly, cup manufacturers use PE-coated paper for production. In recent years, PLA-coated paper(bio-degradable) has also been used in certain markets along with rising environmental awareness. For paper cup industrial, we suggest manufacturers use a minimum PE thickness of single PE 18g/㎡ or double 18/12 g/㎡. According to the common sense of paper cup machinery(paper thickness is more important than base weight). The paper thickness tolerance of each size should be within ±0.02mm.

According to function: Generally speaking, cold cups need double PE coated paper and hot cups need single PE coated paper.

According to cup size: Normally, the bigger the cup’s volume, the thicker paper should be. Such as 12oz-16oz cups need 0.31mm-0.41mm thickness paper according to purposes of use both thicker or thinner paper can be formed, but the holding feeling is different when using.

According to use area: People from different areas have different preferences for paper thickness. Europe or North American areas prefer thicker paper usage for cups.

Features of Disposable Paper Tea Cup Making Machine

Reliability

An intelligent paper tea cup manufacturing machinery is provided with the advantages of high performance, high efficiency, and high quality. The overall steel plate machinery body and oil-spraying lubrication system ensure the normal and stable long-term operation of the paper cup-making equipment. Besides, YG Engineering Machinery also supplies the plastic container making machine, please leave your requirement to us.

High Efficiency & Energy Conservation

Advanced high-precision cylindrical cam driving unit working with a gear drive system make sure the precise working of every station. Bottom paper feeding is controlled by the servo tracking system and raw material paper can be saved effectively.

Foreign Technical

The paper bottom heating system(Switzerland Leister) uses 2 steps of flameless heating. Every step in production is monitored by Photocell and reported.

User-Friendly Design

The function of the machine is controlled by a human-computer interface and PLC system. Manual operation can be replaced by automatic paper cup counting and a collection table with the appropriate setting. Contact us to get a fully automatic paper cup manufacturing machine price now.

Paper Cup Manufacturing Machine

Advantages of Fully Automatic Paper Cup Machine

- Automatic reminder when the paper fan comes short.

- When a multi-paper fan is delivered, it can stop automatically.

- Ultrasonic needle automatic inspects, the ultrasonic system stops working when paper fan not delivered.

- Automatic paper fan tracks and delivery.

- The Servo motor sends bottom paper only when the OPTO switch confirms the paper fan is delivered.

- Filly automatically stops when the paper cup falls down.

- When the bottom sealing temperature does not reach the expected level, it can stop automatically.

- Leister heaters automatically stay at a safe location when the machine stops for analysis.

- Adopt automatic inspection function.

- The cup collector adopts a quantity control function, cup quantity per package is adjustable according to requirement.

- The equipment can equip with a paper cup lid making machine or a plastic cup lid forming machine.

Related Machine With Paper Cup Making Machine

YG paper cup machine supplier offers a variety of paper cup processing equipment. For example, paper straw machines, paper plate machines, packaging machines, and other equipment. In addition, YG also produces paper bowl machines, coffee cup machines, tea cup machines, etc. Please contact us to get a paper cup machine quote.