The CNC stirrup bending machine(CNC rebar bending machine) is a multifunctional steel bar processing equipment. It integrates straightening, bending forming, and cutting into one. It adopts digital program control and widely used in processing round steel, screw steel, and cold-drawn wire. CNC rebar bending machine is widely used in the processing of stirrups in construction, bridge tunnels, prefabricated components, and other projects. YG Steel Rebar Processing Equipment Manufacturer also provides steel bar upsetting machines, straightening and cutting machines, thread rolling machines, I-beam bending machines, and other steel bar processing equipment.

Automatic Stirrup Bending Machine Parameters

| Model | YG-1 | YG-2 | YG-3 | YG-4 |

| Single wire(mm) | Round steel 4-10mmDeformed steel bar 4-8mm | Round steel 4-12mmDeformed steel bar 4-10mm | Round steel 5-14mmDeformed steel bar 5-12mm | Round steel 4-12mmDeformed steel bar 4-10mm |

| Double wire(mm) | Round steel 4-6mmDeformed steel bar 4-6mm | Round steel 4-8mmDeformed steel bar4-8mm | Round steel 5-10mmDeformed steel bar 5-10mm | Round steel 4-8mmDeformed steel bar 4-8mm |

| Max bending angle | ±180° | ±180° | ±180° | ±180° |

| Center pin diameter | 16、18、20 | 16、18、20 | / | 16、18、20 |

| Maximum towing speed | 60m/min | 60m/min | 110m/min | 110m/min |

| Maximum bending speed | 800°/sec | 800°/sec | 1000°/sec | 800°/sec |

| Machine size | 2600*800*1700mm | 3280*1000*1700mm | 3850*1200*2200mm | 3660*1110*1700mm |

| Device color | Yellow(customized) | Yellow(customized) | Yellow(customized) | Yellow(customized) |

| Pieces Processed | ≤2 | ≤2 | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa | / | ≥0.8mpa |

| Total Power | 14kw | 20kw | 32kw | 23.5kw |

| Working temperature | -5°C~40° | -5°C~40° | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° | ±1° | ±1° |

| Average power | 4.5KW/h | 5KW/h | 5KW/h | 5KW/h |

| Total weight | 1150KG | 1350KG | 2200KG | 1550KG |

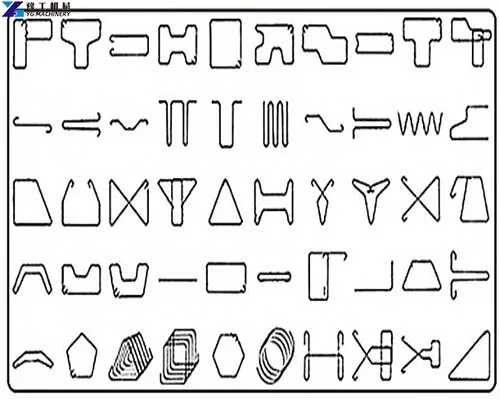

Applications and Formed Shapes

Hoop bending machine is multi-purpose, it can be used for stirrup, straightening, and cutting. It can process round steel, screw steel, and cold-drawn wire into various sizes and shapes. The CNC steel hoop bending machine can process square, rectangular, rhombus, single, and double-headed hooks and other components. From raw materials to finished products, one-time processing and molding, high production efficiency.

Why Use Stirrup Bender?

With the development of industry, the demand for steel bars has increased, and the demand for steel bar shapes has gradually increased. Ordinary steel bar processing machinery has a single function, the processing speed is slow, and the efficiency of manual operation is low. The emergence of automatic stirrup bender meets the needs of diversified bending hoop processing and the needs of industrial production. It can process various types of steel bars into various shapes, one-time forming, and high production efficiency. Automatic equipment can replace 4-6 people to operate, with a high degree of automation.

How to Straighten by Automatic Stirrup Bender?

The automatic stirrup bending machine can not only be used for bending and hooping steel bars but also for straightening. The straightening steps are as follows:

- Put the steel bar into the feeding port of the CNC steel bar bending machine, and make sure that both ends of the steel bar are on the center line of the feeding wheel.

- Turn on the power of the equipment to start the machine and select the straightening function on the machine control panel

- Adjust the straightening wheel of the automatic stirrup bending machine so that it is opposite to the bending direction of the steel bar.

- Adjust the feed wheel and discharge wheel of the CNC rebar bending machine to keep the steel bar straight between the feed and discharge wheels.

- Adjust the pressure wheel so that it is in close contact with the steel bar to ensure that it will not slip out or twist.

- Start the machine for straightening, check whether the steel bars are completely straightened during the straightening process, and adjust again if not.

- Take out the straightened steel bar from the outlet for the next step of processing.

Stirrup Bending Machine Features

- The bending system adopts a pneumatic telescopic, high-strength material bending shaft, reasonable design, long service life

- The bending angle can be adjusted arbitrarily according to the actual engineering situation to meet the various needs of customers.

- The high efficiency of dual automatic wire feeding ensures the best precision in bar straightening.

- This equipment is small in size, light in weight, compact in structure, solid, and reliable.

- The machine adopts a closed structure and utilizes gear splash lubrication, so the working time is long.

- The high degree of automation, and fast processing speed.

- Versatile in function, this stirrup bender combines straightening, bending forming, and shearing in one.

- Saving raw materials, continuous molding, and almost no rebar scraps.

About YG Rebar Processing Machinery Manufacturer

YG is a company focusing on the R&D, manufacturing, and sales of construction machinery. The company’s main products include concrete cutting machinery, steel bar processing machinery, prestressing machinery, and other equipment. Among them, the steel bar processing equipment includes a steel bar bending machine, straightening machine, tube end forming machine, arc punching machine, deburring machine, and so on. If you want to know more about reinforcement equipment, please contact us.