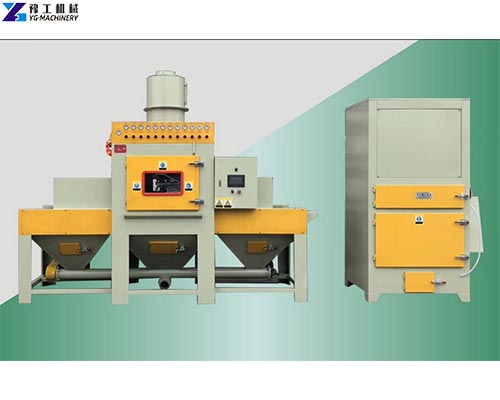

Automatic Sandblasting Machine For Sale

The automatic sand blasting machine, also known as the grit blasting machine, is a fully automatic conveying sandblasting machine. It is a sandblasting machine widely used for dusting, polishing, cleaning, and engraving metal surfaces. The sandblasting technology of YG Machinery is imported from Japan and combined with the series of automatic sandblasting machines developed in the current market. Compared with similar small sand blasting machines, the efficiency of YG’s automated sandblasting machine can be increased by 30%. What’s more, the loss of abrasive and energy consumption can be reduced by 20%. Please leave your message if you want to buy high-quality cheap sandblasting equipment for sale recently.

12 Spray Gun Automatic Conveying Sand Blasting Machine Overview

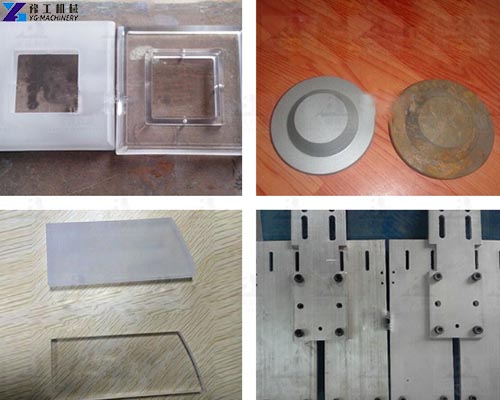

Application: used to remove impurities on metal surfaces, to achieve surface strengthening, polishing, and engraving on non-coated surfaces.

Obtaining different sand patterns: Choose different sand materials to obtain different sand patterns.

Applicable sandblasting media: brown corundum, emery, glass sand (beads)

Sandblasting process: Put the objects to be sandblasted on the conveyor belt, and the conveyor belt conveys the objects into the sandblasting room for sandblasting.

Field: Widely used in ships, bridges, hydraulic engineering, aircraft manufacturing, instrumentation, electronic industry, and other fields.

Other Sandblasting Machine Types: Dry sand blasting machine, wet sandblasting equipment, frozen abrasive blasting machine.

Popular countries: Australia, Egypt, Pakistan, Kenya, Sri Lanka, Ireland, Malaysia, Turkey, Bangladesh.

Parameters of mini sand blasting machine

| Model | YG400 | YG500 | YG600 | YG700 |

| Diameter(mm) | 400 | 500 | 600 | 700 |

| Height(mm) | 1100 | 1150 | 1200 | 1350 |

| Volume(m³) | 0.15 | 0.2 | 0.3 | 0.4 |

| Pressure(MPa) | 0.5-0.8MPa | |||

| Efficiency(m³/h) | —— | —— | 5-10 | 6-11 |

| Air consumption(m³/min) | 3-7m³/min |

Parameters of Automatic Sand blasting Machine

| Model | YG800 | YG900 | YG1000 |

| Diameter(mm) | 800 | 900 | 1000 |

| Height(mm) | 1900 | 2000 | 2000 |

| Volume(m³) | 0.8 | 0.8 | 1 |

| Pressure(MPa) | 0.5-0.8MPa | ||

| Efficiency(m³/h) | 10-12 | 10-20 | 10-30 |

| Air consumption(m³/min) | 3-7m³/min |

Application of Automated Grit Blasting Machine

The conveyor-type automatic sandblasting machine is mainly used for sandblasting the surface of various flat metal, plastic, and aluminum parts. Such as mobile phone shells, notebook shells, acrylic, glass products, car brake pads, and other product surface sandblasting.

An automatic sand blasting machine is the most ideal method for large-area cleaning of metal surfaces before coating. It can achieve the function of surface strengthening, polishing, and carving for non-coated surfaces. If you are looking for the automated conveyor sandblasting machine price, please contact us.

Principle of Automatic Sand blasting Cabinet

The working principle of sandblasting machine is basically similar. They use air pressure to spray abrasives onto metal surfaces for grinding. The abrasive can be silica sand, copper slag, iron sand, etc. The main purpose is to remove impurities and oxide layers on the metal surface and increase the surface area. Therefore, the sandblasting machine can improve the surface adhesion of the coating and improve the quality of the coating.

The automatic conveyor belt blasting machine is installed with 12 spray guns in the blasting chamber. When the conveyor belt transports the object into the blasting chamber, the spray gun is aimed at the surface of the object for jet grinding. YG sandblasting machine has high sandblasting precision and high production efficiency. If you are ready to purchase a sandblasting machine for your project, please feel free to contact us.

What Are The Advantages of a Grit Blasting Machine?

Due to the impact and cutting action of abrasives on the surface of the workpiece, the automatic sandblasting machine can obtain a certain degree of cleanliness and different roughness on the surface of the workpiece. As a result, the mechanical properties of the surface of the workpiece are improved. Therefore, improving the fatigue resistance of the workpiece. At the same time, the automatic grit blasting machine increases the adhesion between it and the coating. And extends the durability of the coating film. If you just need to purchase automatic sandblasting equipment for sale, welcome to inquire.

The conveyor sand blasting machine is also conducive to the leveling and decoration of the paint. Removing impurities, variegated colors, and oxide layers on the metal surface. At the same time, the surface of the medium is roughened. The residual stress of the workpiece is eliminated and the surface hardness of the substrate is improved. If you have any questions about our sandblasting equipment, leave your message freely. In addition, if you need to customize sandblasting room, please contact us. As professional automatic sand blasting machine manufacturer, we provide small sandblasting machines and automatic sandblasting room custom service.

Features of an Automatic Sandblaster Machine

- Simple operation. Ordinary workers can operate the sandblaster machine proficiently after half an hour of training. In addition, our automatic sand blaster equipment for sale has an advanced automatic control system to prevent workers from misoperation.

- High production efficiency. The average daily processing volume of a large sandblasting room is equivalent to the sandblasting workload of 50-80 skilled workers.

- High precision of sandblasting. Mobile grit blasting machines for sale can remove tiny and hidden burrs without being restricted by the shape of the product, with a high pass rate and stable sandblasting quality.

- A grit blasting machine can remove burrs from small rubber-plastic alloy products. Brittle plastic products, magnesium alloy, zinc alloy, and aluminum alloy castings with complex structures and shapes.

- Abrasive blasting machines do not damage the surface of the product, improve the appearance quality of the product, and increase the service life of the product.

- Equipped with 12 spray guns, each gun can be controlled individually. And it is equipped with a blowing gun to reduce the sand attached to the workpiece after processing.

- YG automatic sand blasting machine manufacturers can design sandblasting equipment according to customer workpiece size, shape, and output.

What are other types of sandblasting machines?

At present, YG also supplies other three types of portable and automated conveyor sandblasting machines. There is a dustless wet sandblasting machine, a dry sandblasting machine, frozen sandblasting machine. Available sandblasting materials are: river sand, yellow sand, steel shot, steel shot, cut shot, brown corundum, diamond, quartz, and so on. Which kind of abrasive grit blasting machine do you need?

[lgc_column grid=”50″ tablet_grid=”50″ mobile_grid=”100″ last=”false”]

Wet Sand Blasting Machine

[/lgc_column] [lgc_column grid=”50″ tablet_grid=”50″ mobile_grid=”100″ last=”false”]

Dry Sand Blasting Machine For Sale

[/lgc_column]Wet Blasting Machines For Sale

Compared with a dry sandblasting machine for sale, the biggest feature of an automatic wet sandblasting machine control the dust pollution in the sandblasting process well. And improve the sandblasting technology of sandblasting operation. Dry blasting becomes water blasting, which is a major change in blasting processing methods. If you are looking for sand blasting machine manufacturers, we will be your ideal choice.

The wet blasting equipment for sale takes the grinding fluid as the feeding power of the grinding fluid. And then, transfers the evenly stirred grinding fluid (the mixture of abrasive and water) to the spray gun through the grinding fluid pump. As the acceleration power of the grinding liquid, the compressed air enters the spray gun through the air pipe. In the spray gun, the compressed air accelerates the grinding fluid entering the spray gun. Mixture water is ejected through the nozzle and sprayed onto the processed surface to achieve the desired processing purpose. In the water sandblasting machine, the grinding fluid pump is the power supply. And compressed air is the acceleration power. Contact us to get a wet automatic sandblasting machine price right now.

Wet Sandblaster Cabinet For Sale[/caption]

Dry Small Sandblasting Machine

Dry sandblasting machine equipment divides into three types according to the spraying method: press-in type, suction type, and centrifugal type.

The press-in type of sandblaster machine is to spray compressed air and abrasive while mixing in the same container. So that the compressed air is fully utilized. And the airflow and sand flow are easy to adjust. The ideal mixing ratio (air and abrasive) can be obtained. Press-in type of automatic sandblaster machine is a high efficiency, low energy, and abrasive consumption, and has a wide range of uses. Suitable for large-area cleaning, etc. are the biggest features of the press-in type of portable blasting machine. If you are looking for a reliable automatic sandblasting machine factory, don’t hesitate to contact us.

The suction-type dry sandblasting machine is powered by compressed air, and the negative pressure is formed in the spray gun through the high-speed movement of the airflow. And then, suck the abrasive into the spray gun through the sand pipe and shoot it through the nozzle. Sprays it to the processed surface to achieve the expected processing purpose. In the suction dry automatic grit blasting machine for sale, compressed air is both the feed power and the acceleration power of the jet.

YG Different Size Sandblasting Equipment For Sale[/caption]

Freezing automatic abrasive blasting machine

The full name is the automatic jetting frozen trimming machine. The frozen abrasive blasting machine is mainly used to replace the manual deburring of rubber molded parts. Precision injection molding and die casting products. The freezing automatic sandblasting machine uses the low-temperature freezing effect of liquid nitrogen to embrittle rubber-plastic alloy materials. At this time, the burrs are embrittled before the product. Within the time difference between the burrs and the products. The high-speed injection of polymer particles is used to hit the product burrs to remove the burrs of rubber-plastic alloy products and aluminum and zinc alloy products. YG Machinery has high-efficiency automatic sandblaster equipment for sale. Leave your requirement if you are ready to buy the automatic sandblasting machine.

Related Products

Regarding construction machinery, we have other products and equipment for you to choose from. For example, down the hole drilling machine, water well drilling rig, small water well drilling equipment. road line marking machine, rebar straightening and cutting machine, rebar bending machine, beam bending machine. Concrete wall saw, pile breaker machine, hydraulic rock splitter. Strand pusher, hollow hydraulic jack, etc. What kind of construction machine are you looking for? Please feel free to leave your contact information. We will reply to you as soon as possible.

Email: admin@yugongengineering.com