What is a CNC fiber laser cutting machine?

The CNC fiber laser cutting machine is to focuses the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point. At the same time, the high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, so as to achieve the purpose of cutting. We have a fiber laser cutter for sale. Contact us to get the YG CNC laser cutting machine price now.

Parameters

| X, Y Working Area | 1500*3000mm |

| Laser power | 500W–800W–1000W–1500W |

| Resolution | 0.025mm |

| Reposition precision | ±0.02mm |

| Maximum cutting speed | 60m/min |

| Maximum acceleration | 1.2G |

| Operating Voltage | Ac 380V 50Hz |

| Total power | <10KVA |

| Machine operating temperature | 5–45℃ |

| Working humidity | 5%—95% |

| Dimensions | 4500mmX2200mmX1600mm |

| Weight | 4700KG |

| Protective glass | 1 set |

| Transmission mode | precision double drive |

| Laser type: fiber laser | fiber laser |

| Support graphic format | DWD、DXF、JPGE、PCX、AI、TIFF、PLT、CDR、BMP、GIF |

Advantages of fiber laser metal cutting machine

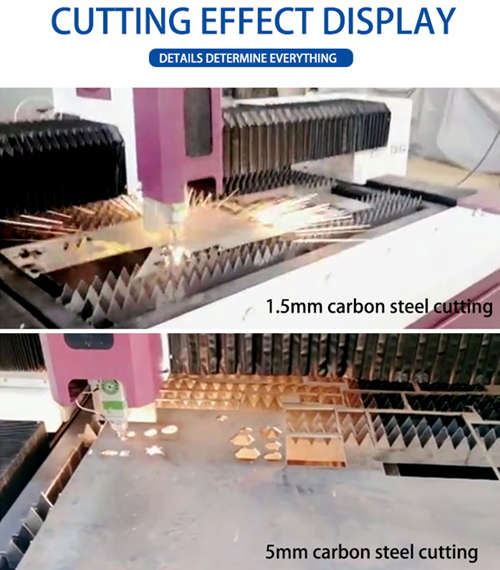

The laser cutting process uses an invisible beam to replace the traditional mechanical knife. It has the characteristics of high precision, fast cutting, not limited to the limitation of cutting patterns. Automatic typesetting, saving materials, smooth cutting, and low processing cost. Laser cutting machines will gradually improve or replace traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece. And it will not scratch the surface of the workpiece during work. If you are looking for a CNC laser cutting machine price, leave your requirement to us.

Laser cutting speed is fast, the incision is smooth and flat. Generally, no need for subsequent processing. The cutting heat affected zone is small, the plate deformation is small. And the slit is narrow (0.1mm~0.3mm). The cut has no mechanical stress and no shearing burrs. Machining accuracy is high, the repeatability is good. And the surface of the material is good. CNC programming can process any plan. And it can cut the whole board with large size without opening the mold, which is economical and time-saving. Therefore, If you are ready to buy the best fiber laser cutting machine, send your message to us. You will get a great fiber laser cutting machine price from YG Machinery.

Application of fiber laser cutting machine

Compared with traditional cutting processes such as oxyacetylene and plasma, the laser cutting speed is fast. The slit is narrow, and the heat-affected zone is small. The cutting edge has good verticality and smoothes the cutting edge. At the same time, there are many kinds of materials that can be laser cut. Including carbon steel, stainless steel, alloy steel, wood, plastic, rubber, cloth, quartz, ceramics, glass, composite materials, etc. With the rapid development of the market economy and the rapid development of science and technology. Laser cutting technology has been widely used in automobiles, machinery, electricity, hardware, and electrical appliances. YG Machinery has a high-quality CNC metal laser cutter for sale. As a professional laser cutting machine manufacturer, you will get a surprise CNC laser cutting machine price from us definitely.

Laser cutting machine work process

During the cutting process of the laser cutting machine. The beam is focused by the lens of the cutting head into a small focal point so that the focal point can reach a high power density. At this time, the heat input by the beam far exceeds the part of the heat reflected, conducted, or diffused by the material. And the material is quickly heated to the melting and vaporization temperature. At the same time, a high-speed airflow will melt from the coaxial or non-coaxial side. And the vaporized material is blown out to form holes for cutting the material. With the relative movement of the focus and the material, the hole forms a continuous slit with a very narrow width to complete the cutting of the material.

Principle of CNC metal cutting

Laser is a kind of light, like other natural light. The transition of atoms (molecules or ions, etc.) produce laser light. But it is different from ordinary light in that the laser only relies on spontaneous emission for a very short period of time. And the subsequent process is completely determined by the excitation radiation. Therefore, the laser has a very pure color, almost no divergent directionality. And the extremely high luminous intensity and high coherence.

Laser cutting is achieved by applying high power density energy generated by laser focusing. Under the control of the computer, discharge the laser by pulse. In this way, a controlled repetitive high-frequency pulsed laser is output to form a beam with a certain frequency and a certain pulse width. The pulsed laser beam is guided and reflected by the optical path and is focused on the surface of the processed object through the focusing lens group. So as to form tiny, high-energy-density light spots. The focal spot is near the surface of the workpiece and melts or vaporizes the material at an instant high temperature. Each high-energy laser pulse instantly sputters a tiny hole on the surface of the object.

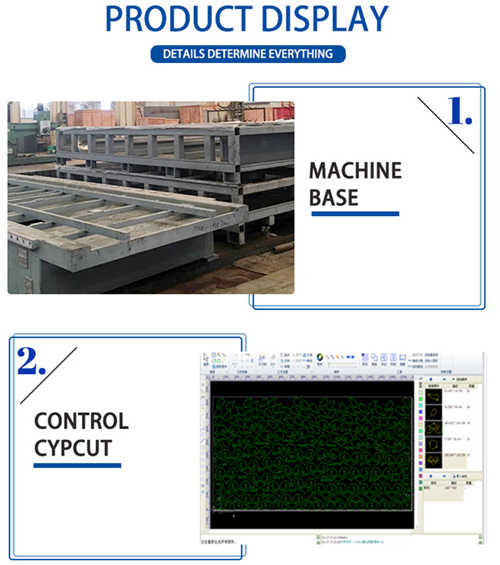

CNC system

Under computer control, the laser processing head and the processed material will perform continuous relative movement according to the pre-drawn graphics. So that the object will be processed into the desired shape. The process parameters (cutting speed, laser power, gas pressure, etc.) and motion trajectory during slitting are controlled by the numerical control system. And the slag at the slit is blown away by a certain pressure of auxiliary gas. Now tell us your specific needs, so we can give you an accurate CNC laser cutting machine price for your reference. In addition, the YG1530 fiber laser cutting machine is our hot sale laser cutting machine model. You can click to know more details.

Other Machines

Regarding metal processing machinery, we have a series of equipment for you to choose from. For example, rebar straightening and cutting machine, rebar bending machine. Automatic sandblasting machine. Also, we have a concrete wall saw, pile breaker machine, hydraulic rock splitter. Strand pusher, hollow hydraulic jack, etc. What kind of machine are you looking for? Please feel free to leave your contact information. Our sales manager will contact you shortly.