What Is A Metal Punching And Shearing Machine?

The punching and shearing machine (iron angle cutting machine) is a combined metal processing equipment. It has the functions of punching, shearing, shearing, and bending. This metal punch and the shear machine is a processing machine for metal cutting, suitable for rapid cutting, punching, bending, etc. of channel steel, angle steel, round steel, and square steel. It is widely used in construction sites, bridge construction, metallurgical plants, power erection, and other fields. The iron angle cutting machine has the characteristics of simple operation, low energy consumption, and low maintenance cost. The metal punch and shear machine is the preferred machine for metal processing in modern manufacturing. If you want to get the punching and shearing machine price, please click the below button.

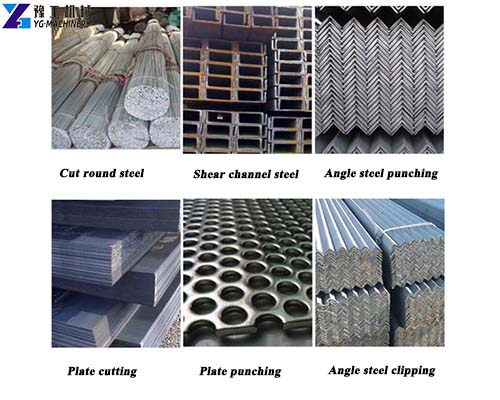

Punching And Shearing Machine Applicable Materials

YG mechanical iron angle cutting machine is suitable for many kinds of metal steel. For example, metal, angle steel, channel steel, strip steel, square steel, round steel, angle steel plate, aluminum profile, scrap steel bar, iron plate, copper plate, aluminum plate, iron plate, steel plate, scrap angle steel, etc. If you don’t know which model of metal punching and shearing machine to choose, please feel free to contact us. We will recommend the most suitable multifunctional combined punching and shearing machine for you according to the metal reinforcement you want to punch and shear and your budget.

Multifunctional Punching And Shearing Machine For sale

YG Machinery has two types of multifunctional punching and shearing machine for sale. One is a mechanical multifunctional punch and shear machine. The other is a hydraulic notching machine. This page mainly introduces YG’s mechanical multifunctional punch shear machine. If you are looking for an efficient and stable punch and shear machine for sale, YG Machinery will be your best choice. The following are the parameters of the hot-selling multifunctional iron angle cutting machine (QA32-8B, QA32-10B, QA32-12B).

YG QA32-8B Punch And Shear Machine

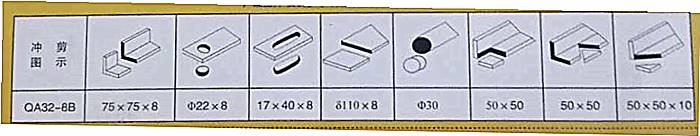

QA32-8B Punching And Shearing Machine Parameters

| Model No | QA32-8B |

| Voltage | 380V,50(60)Hz |

| Motor Power | 2.2KW |

| Punching diameter | 22mm(Round hole diameter)*8mm(Thickness) |

| 40mm(oblong hole diameter)* 17mm(Length)*8mm(Thickness) | |

| Shaft Size | 30mm |

| Angle steel | 75*75*8 |

| Channel steel | 8# |

| Number of trips | 30Times/Min |

| Maximum shear force | 360KN |

| Tool stroke | 27mm |

| Total Weight | 550KG |

| Dimensions | 900*500*1100 |

QA32-8B Application

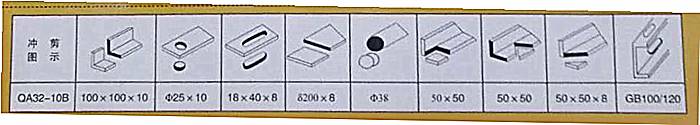

QA32-10B Parameters

| Model No | QA32-10B |

| Voltage | 380V,50(60)Hz |

| Motor Power | 3KW |

| Punching diameter | 25mm(Round hole diameter)* 10mm(Thickness) |

| 40mm(oblong hole diameter)* 18mm(Length)*10mm(Thickness) | |

| Shaft Size | 38mm |

| Angle steel | 100*100*10 |

| Channel steel | 120# |

| Number of trips | 30Times/Min |

| Maximum shear force | 500KN |

| Tool stroke | 30mm |

| Total Weight | 700KG |

| Dimensions | 1100*700*1250 |

QA32-10B Application

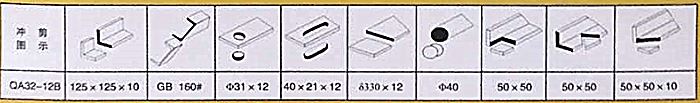

QA32-12B Parameters

| Model No | QA32-12B |

| Voltage | 380V,50(60)Hz |

| Motor Power | 4KW |

| Punching diameter | 32mm(Round hole diameter)*12mm(Thickness) |

| 40mm(oblong hole diameter)* 21mm(Length)*12mm(Thickness) | |

| Shaft Size | 40mm |

| Angle steel | 125*125*12 |

| Channel steel | 160# |

| Number of trips | 30Times/Min |

| Maximum shear force | 900KN |

| Tool stroke | 36mm |

| Total Weight | 1100KG |

| Dimensions | 1100*600*1450 |

Note: Only the QA32-12B punch and shear machine are divided into three-station and five-station.

The three-station are suitable for drying slightly thicker materials,

The five-station is mainly used for punching the small face of channel steel.

QA32-12B Application

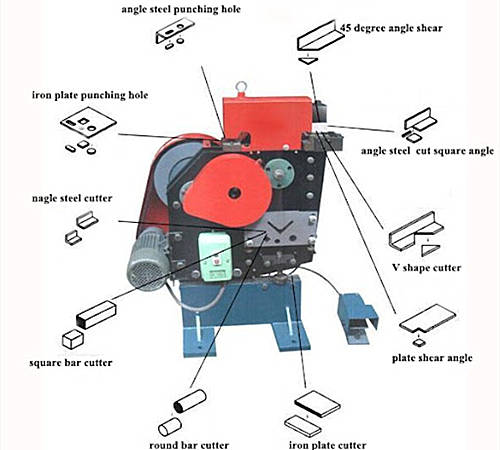

Features Of Punch And Shear Machine

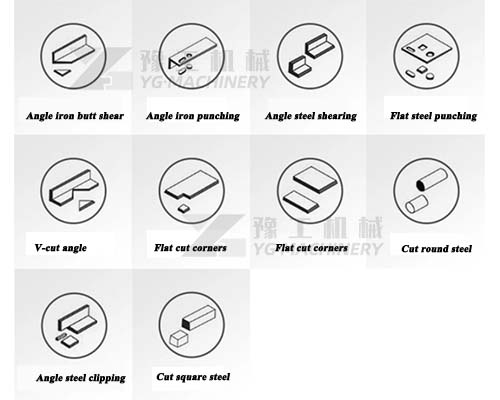

The mechanical multifunctional metal punch and the shear machine is a kind of manual cutting, shearing, and punching processing mechanical equipment for metal materials. Metal punching and shearing machines use overlapping two-level levers, sliders, etc., to drive the slide plate equipped with three types of cutting blades to move up and down. And the fixed blade is mounted on the frame to complete the shearing and punching process. The combined shear and punch machine have a compact structure, low cost, small size, lightweight and convenient operation.

Contact us freely if you need the shear and punch machine prices.

Punch And Shear Machine Factory

Related Products

This page introduces the mechanical punch and shear machine. If you are looking for a hydraulic ironworker machine, please click it. At the same time, we have another series of products. YG Machinery is a professional manufacturer of steel, steel pipe, and metal processing machinery and equipment. Rebar straightening and cutting machines, steel bar bending machines, rebar upsetting machines, thread rolling machines, I-beam cold bending machines, H-beam bending machines, hydraulic scrap metal shear for excavators, etc. are also our best-selling products. Please feel free to contact us if you need these machines.