The small portable dustless sandblasting machine is the category of air-conveying machinery. The wet grit sandblasting machine uses compressed air in a pipeline to transport powdery particles (1~4mm in diameter) from one place to another. In the process of transforming kinetic energy into potential energy, the high-speed moving sand particles wash the surface of the object to achieve Improve the surface quality of objects. YG Machinery has many types of sandblasting equipment for sale. Please feel free to contact us if you are looking for a quality and cheap wet blasting machine for sale. Click here to know more about the automatic sandblasting machine.

Parameters

| Model | YG-600 | YG-700 | YG-800 | YG-1000 |

| Volume(m3) | 0.26 | 0.3 | 0.6 | 1 |

| Height | 1150 | 1250 | 1700 | 2000 |

| Sand peening capacity | 5-10(m3/h) | 6-11(m3/h) | 10-12(m3/h) | 10-30(m3/h) |

| Air source configuration | 3(m2/min) | 3(m2/min) | 3.5(m2/min) | 4(m2/min) |

| Control System | Air control | Air control | Air control | Air control |

| Diameter | 600mm | 700mm | 800mm | 1000mm |

What is the Wet Sandblasting Process?

Whether it is a dry blasting machine or a wet blasting machine, they all use compressed air as the main power. The dry sandblasting machine uses dry abrasives, and the water sandblasting machine uses abrasive fluid as raw material. The grinding fluid is made by mixing the abrasive and water in a certain proportion through the grinding fluid pump. The abrasive is transported into the spray gun through the air pipe, and then the compressed air sprays the abrasive liquid to the surface of the object at a high speed to achieve the desired treatment purpose.

How to Choose the Right Sandblasting Machine?

The sandblasting machine can be in the form of a dry sandblasting room/box or a wet sandblasting box. Whether it is dry spray (dry and free-flowing medium) or wet spray (water mixed medium) sandblasting machine. The spray medium is pneumatically accelerated by compressed air and then sprayed onto the surface of the part through a nozzle. The blasting task will determine the choice of dry blasting or water sandblasting machine for sale and which abrasive medium to use. In a dry sandblasting machine and wet sandblasting machine, the nozzles can be installed in a fixed position. Or operated by manual or automatic nozzle manipulators or robots. Email: admin@yugongengineering.com

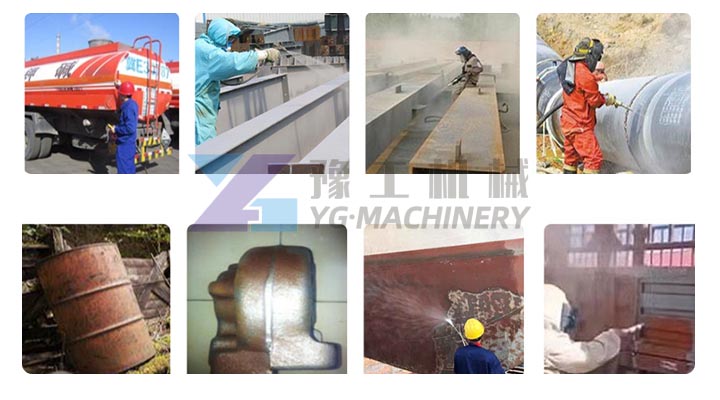

Application of Wet Abrasive Blasting Machine

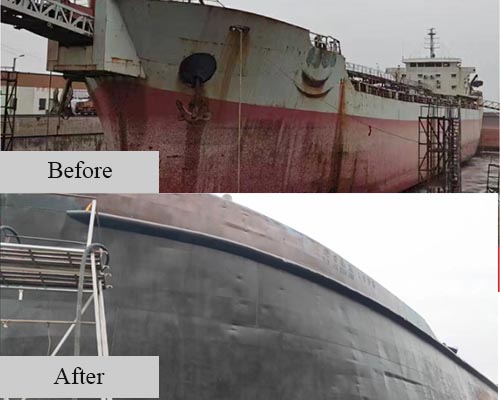

Sandblasting cleaning has a wide application process in mechanical manufacturing. All forging, casting, heat treatment and surface treatment parts must be sandblasted to remove the surface oxide scale, sticky sand, old plating, molten salt heat, rust, etc. View here to learn about YG automatic sandblasting machine for sale. Email: admin@yugongengineering.com

Cleaning of the workpiece surface

The portable wet sandblasting machines can clean the oxide scale, residual salt, and residual oil after heat treatment. The oxide scale and molding sand of colored casting parts. And the oxide scale and molding sand of precision casting without allowance. Residue and micro burr of machined parts. Oxide scale and welding slag of welding parts. Hot-rolled steel, cold-rolled steel, etc. Mold release agent, deposit, etc. Sintering residues on the surface of ceramic components. Flash of plastic parts. Radioactive elements on the surface of objects. Leave your message to get a wet blasting machine for sale price.

Pretreatment before coating the surface of the workpiece

The wet sandblasting machine can be used before painting and baking. And before spraying, metal spraying, galvanizing, chromium, nickel plating, and oxidation treatment.

Other applications

In addition, wet sandblasting machines can also be used for bridges. Hydropower station gates, ships, buildings, and airport runway rubber adhesive layers. Oil stain and attachment of railway carriage, various pipes, containers and tanks, old machine parts, etc. YG water abrasive machine is also often used for residual paint, rust layer, and attachment of containers. And the wrong sintering layer on porcelain scratches on decorative surfaces, etc. Now leave your message to get the blasting machine for sale free quote for your project.

Why choose YG Machinery?

YG Machinery has the most extensive series of sandblasting equipment products. For example, automatic sandblasting machine, mobile sandblasting equipment for sale, and sandblasting room. Rotary sandblasting machine. Water abrasive machine for sale, etc. The wet sandblasting equipment for sale ranges from manual small sandblasting machines for cleaning to highly complex reinforced equipment used in aerospace. Our company has a wealth of experience in wet blasting machine for sale equipment, which is sufficient to prove its largest competitive resource in the industry. We promise to continue to strengthen the blasting process and combine the most cutting-edge mechanical innovation concepts to provide our loyal customers with the most advanced and cheap dustless sandblasting machine prices as always.

Other products

In terms of the metal industry, we have a series of steel bars and steel pipe processing machines for sale. For example, rebar straightening and cutting machine, thread rolling machine, and upset forging machine. Rebar bending machine, steel bar derusting machine, thread rebar couplers, etc. At the same time, we have a road marking machine for city road projects. And down the hole drilling machine for sale and cheap water well drilling rigs.