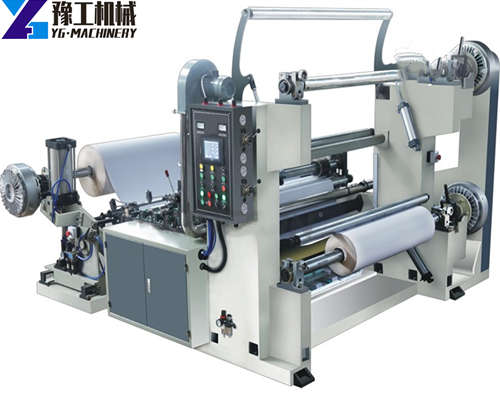

YG Paper Rewinding Machine For Sale

The paper rewinding machine is an important machine for the production of roll toilet paper. The base paper processed by the toilet paper production line is calendered, embossed, and then wound by a paper rewinder. The toilet paper rewinding machine makes the otherwise fluffy paper more compact, in line with the characteristics of paper in modern use. The rewinder is generally used for mica tape, paper, film slitting, and rewinding.YG paper rewinding machine manufacturer designs develops and manufactures toilet paper rewinding machines with different configurations for domestic and foreign customers to choose from. If you want to know more about this device, please click to contact us.

Rewinder Machine

Toilet Paper Rewinding Machine Application

The toilet paper rewinding machine is generally used for mica tapes, paper, non-woven fabrics, and other products. It is also suitable for slitting and winding wide base paper such as kraft paper, bobbin paper, printed paper, and coated paper. The operation is simple and convenient, safe and reliable, and durable.

Why Use a Paper Rewinder Machine?

In the production process of toilet paper, the pulp needs to be made into base paper first. The base paper is then processed by a coater and rewinder to produce the finished paper. The base paper roll processed by the toilet paper production line is relatively soft and may have defects such as damage or ends, and uneven edges on both sides. Therefore, it is necessary to use a rewinder to trim, slit, and splice the base paper, and rewind it on the paper core into a finished paper roll of a certain size and tightness.

Technical Parameters

| Width of the base paper | ≤2100mm |

| Finished product diameter: | Φ60~150mm (adjustable elasticity) |

| The inner diameter of the finished paper core | Φ 32~50mm |

| Diameter of base paper | Φ1100mm |

| Inner dia. of base paper core | 3″ |

| Punching pitch | 4 knives, mechanical adjustment 90~180mm |

| Rewinding speed | 0-200 m/min |

| Punching method | pneumatic separation |

| Paper ejection rack | 1-3 layers |

| Dimensions (L×W×H) | 6500×3100×2600 (mm) |

| Machine weight | 3500kg |

| Total power | 4kW |

| Pneumatic system | 3 HP air compressor, minimum pressure 5kg/cm2 Pa |

The above are the parameters of one of the rewinders provided by Yugong. The width of the base paper it can handle is less than 2100mm, the diameter of the finished product is between 60~150mm, and the inner diameter of the finished paper core is 32~50mm. In addition, YG Machinery also offers other semi-automatic and fully automatic rewinders. If you want to know specific parameters and prices, please contact us.

Multifunctional Paper Slitting and Rewinding Machine Introduction

The paper slitting and rewinding machine adopts the center winding method, which is suitable for slitting and rewinding large diameter coils. This paper slitter rewinder machine is suitable for slitting and rewinding paper, film, aluminum foil, PVC, and other large coils. The slitter rewinder for sale has a simple operating system and full computer touch screen. Dual-frequency conversion synchronous (PLC) control, optional shaftless feeding, automatic feeding. And photoelectric tracking and edge correction system. This paper rewinding machine has the characteristics of fast and stable slitting and rewinding speed, high slitting precision, flat receiving end surface, and long service life. Contact us to get more information about multifunctional slitting and rewinding machine prices.

Multifunctional Slitting And Rewinding Machine

Paper Core Cutting Machine

The paper cutting machine is suitable for cutting paper cores of different thicknesses with an inner diameter of 76mm (3″). The paper cutting machine is convenient for loading and unloading, simple operation, and neat cuts.

Surface Slitter Rewinder

A surface rewinder machine is suitable for slitting and rewinding paper, film, aluminum foil, PVC, and other large coils. The surface slitter rewinder has functions such as frequency converter speed regulation, PLC touchscreen control, automatic meter counting, automatic length fixation, alarm stop, automatic tension control, etc. The surface rewinder machine adopts air pressure feeding and is equipped with a correction device. YG surface rewinder adopts a flat knife/round knife Slitting structure and is equipped with an automatic waste removal device. The machine adopts the surface winding method, which is the best equipment for slitting large coils to small specifications at present. If you are looking for a surface rewinder machine manufacturer, please feel free to contact us.

Surface Slitter Rewinder

Servo Drive Slitting Rewinder For Sale

Scope of application: Servo drive slitting rewinder is suitable for slitting and rewinding all kinds of super large coils. It is suitable for coils such as kraft paper, white cardboard, photographic paper, aluminum foil, PVC plastic, and non-woven materials.

Performance and Characteristics

- The servo drive slitting rewinder machine is stable in operation, high in cutting precision, controlled by a computer touch screen, simple in operation, and convenient in maintenance.

- It adopts three servo motors and servo drive, automatic constant tension, and maintains a balanced operation during acceleration.

- The winding method is the central winding of the upper and lower shafts, and the unwinding method can be equipped with a hydraulic shaftless.

Servo Drive Slitting Rewinder For Sale

Automatic Toilet Paper Rewinder Machine For Sale

As toilet paper production equipment, paper rewinding machines can be divided into automatic toilet paper rewinders and semi-automatic toilet paper rewinders. The automatic toilet paper rewinding machine adopts PLC computer programming technology, man-machine interface operation, automatic glue spraying, frequency conversion speed regulation, edge banding, trimming, and so on at one time. As a professional slitter rewinder manufacturer, YG Machinery will be your ideal partner if you are looking for a rewinding machine price.

Advantage

- Equipped with a processed coreless, solid core, and rolled paper tube toilet paper, the switch between products can be completed in an instant.

- Automatic trimming, glue spraying, sealing, and shaft extraction are completed instantly so that the roll paper is transferred to the band saw for cutting and packaging without paper loss.

- Pneumatic belt feeding, the rewinding shaft, and each shaft have independent tension adjustment mechanisms.

Automatic toilet paper rewinder machine for sale

Features of Automatic Toilet Paper Rewinder Machine

Compact structure, easy to operate

Receiving platform with cutting groove

Rewinding, unwinding, and traction all adopt variable frequency drive technology

PLC programmable controller as the core processing unit

Touch screen as a man-machine dialogue interface

High precision tension control

Automatic attenuation tension taper control

Fixed length deceleration

Fixed-length parking

Forward and reverse function

Static elimination function

Working Process of Slitting and Rewinding Machine

First, cut off the burrs of the original paper.

Second, cut the entire base paper into several widths that meet the user’s specifications.

Third, control the roll diameter of the finished paper roll to make it meet the factory specifications.

Slitting and Rewinding Machine Price

Related Products

As a professional machine equipment supplier, we have a series of slitter rewinding machines for sale. At the same time, we have a tissue paper manufacturing machine, wet wipes making machine, wet wipes production line, nitrile gloves making machine for sale, paper tube making machine, PE gloves manufacturing machine, and so on. If you have any needs, please feel free to tell us at any time.