What Is DTH Drilling Rig?

The DTH drilling rig (down-the-hole drilling machine) is a kind of drilling machine, which is mainly used for drilling in rock formations. The down-the-hole drilling rig uses the impactor and the DTH drill bits submerged into the bottom of the hole to impact and crush the rock. Therefore, it is called down-the-hole drilling machine equipment. YG DTH drill rig machine is widely used in metal mines, hydropower, transportation, building materials, harbors, and national defense projects.

Application Of DTH Drilling Machine

Down the hole drill rig can drill holes in rocks above medium hard (f ≥ 8). Therefore, down-the-hole drilling machine equipment is suitable for large-diameter blast hole drilling in small and medium-sized mines. Road construction, water conservancy, and rock engineering. And drilling anchor holes in slope support, tunnel support, and foundation pit support. The main drilling object of the DTH drilling machine is the rock stratum. Contact us to get a cheap YG DTH drilling machine price.

Working Principle Of Mining Drilling Rig

The working principle of the mining drilling rig is the same as other rock drilling rigs. Which includes the drilling process of impact, rotation, ballast removal, and advancement. DTH machine belongs to percussion rotary drilling. The difference is that the impactor of the down-the-hole drilling machine is installed at the front end of the drill rig rod, submerged into the bottom of the hole. And continues to advance as the drilling extends.

Classification of DTH Drilling Rig Machine

1: Divided by walking mode

Small outrigger-type down-the-hole drill rig (YGD70-80-100-120)

Large crawler DTH drill rig machine carriage (YGL100T 130 /YGM150T 153 /YGH320)

2: Divided by work power

Pneumatic-electric linkage down the hole drilling machine. Pneumatic-hydraulic linkage (fully hydraulic) down the hole drilling machine. Fully pneumatic down-the-hole drilling machine (SKQ100).

3: According to the wind pressure level

Low wind pressure L DTH drill rig. Medium wind pressure M DTH drilling machine. High wind pressure H down the hole drilling machine.

4: According to the hydraulic power configuration of the drill rig

Diesel-driven down-the-hole drill rig. Diesel-electric dual-use DTH drill rig. Electric down-the-hole drill rig(needs to be customized).

5: According to different places of use, DTH rigs can be divided into underground DTH drilling machines and open-air DTH drilling machines.

6: According to the different drilling diameters

Light-duty down-the-hole drilling rigs (with an aperture of 80~100mm). Medium-duty down-the-hole drilling rigs (with an aperture of 130~180mm). Heavy-duty down-the-hole drilling rigs (with an aperture of 180~250mm).

As a professional DTH drilling rig manufacturer, YG Machinery provides all series down-the-hole drill rigs. Which kind of down-the-hole drilling equipment do you need? Please leave your requirements.

Small Outrigger Type DTH Drilling Rig Parameters

| Model | YGD70/YGD80 | YGD100 | YGQ100 | YGB120 |

| Drilling Dia. | 90-120mm | 90-130mm | 90-130mm | 90-130mm |

| Apply rock | ≥20 | ≥20 | ≥20 | ≥20 |

| Drilling depth | 15m | ≥25m | ≥25m | ≥30m-40m |

| Drilling rotate speed | 110r/min | 110r/min | 110r/min | 110r/min |

| Working air pressure | 0.5-0.7Mpa | 0.5-1.0Mpa | 0.5-1.0Mpa | 0.5-1.0Mpa |

| Air consumption | 4m³/min | 6m³/min | 12m³/min | 10m³/min |

| Cylinder Dia. | 90mm | 140mm | 140mm | 140mm |

| Propulsion stroke | 1070mm | 1070mm | 1070mm | 1070mm |

| Max propelled force | 3600N/8000N | 9600N | 9600N | 9600N |

| Electric motor power | 3KW/4KW | 4KW | / | 4KW/5.5KW |

| Electric motor voltage | 380V | 380V | / | 380V |

| Rated speed | 1440r/min | 1440r/min | 3200r/min | 1440r/min |

| Drilling rod OD | 42mm | 50-60mm | 50-60mm | 60mm |

| Drilling rod length | 1025mm | 1025mm | 1025mm | 1025mm |

| Dimension | 1740*260*420 | 2280*440*550 | 2230*380*550 | 2230*380*550 |

| Weight | 280/320KG | 470KG | 450KG | 460/480KG |

We have a series of DTH drilling equipment for sale. If you want to get large crawler DTH drill carriage (YGL100T 130 /YGM150T 153 /YGH320) specifications, please feel free to contact us.

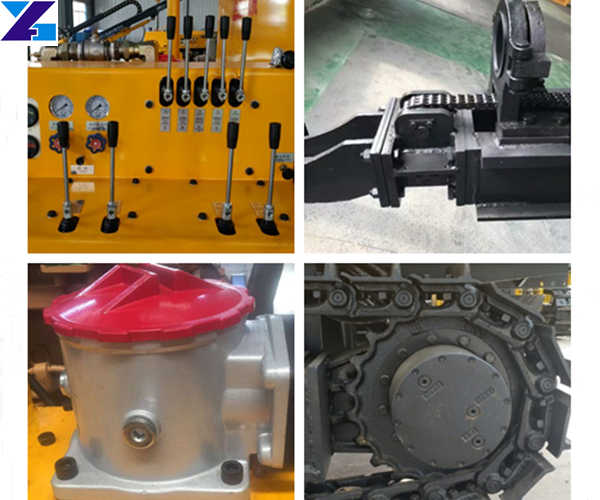

Crawler Type Down The Hole Drilling Machine Advantages

- The portable DTH drill rod holder reduces the time and cost of workers’ handling.

- DTH drill machine operation table of the whole machine is moved forward by 80mm, which is suitable for single-person operation and convenient to observe the drilling progress.

- YG’s whole Strata Drilling Rig is equipped with a sleeve roller chain. Both the fixed pulley and the movable pulley are driven by a sprocket, which improves practicability and durability.

- The pressure gauge in the dashboard can quickly diagnose drill rig faults.

- The traveling part is equipped with a 0.5S reinforced traveling motor to replace the original 1.6S steel ball motor.

- The rotary motor of the powerhead is improved from the original 700 swing cylinder motor to a high-speed cycloid BM630 motor. Click the following button to get the latest DTH drilling machine price.

As one of the best DTH drilling rig manufacturers, you can get the ideal construction plan from us. Just leave your requirement by email or message form.

DTH Drill Machine – Impact Rotary Drill

YG down the hole drilling machine is an impact rotary drill. Its internal structure is different from ordinary rock drills. The air distribution and piston reciprocating parts of the down-the-hole drill are independent, namely the impactor. The front end of the impactor is directly connected to the DTH bit. And the rear end is connected to the drill rod. When rock drilling, the impactor dives into the hole, and the piston (hammer) in the impactor reciprocates to strike the shank through the gas distribution device (valve). So that the strata drilling rig bits impact the rock at the bottom of the hole. Waiting for your inquiry.

Impactor

The high-speed rotation of the impactor in the hole is realized by a separate rotation mechanism. That is a motor or a pneumatic rotating device outside the hole. And a drill rod connected to the back end of the impactor. Rock dust produced during rock drilling is flushed out of the hole by the mixed gas of wind and water. The mixed gas is injected into the impactor through the center of the drill rod by the powder discharge mechanism. And then, enters the bottom of the hole through the air groove on the impactor cylinder. If you have any questions, please feel free to contact us.

Structure Composition Of Down The Hole Drill Rig

The mining drilling rig consists of a drill rod, DTH button bits, and an impactor. When drilling, use two drill rod extensions to drill. A rotary air supply mechanism consists of a rotary motor, a rotary reducer, and an air supply gyrator. Slewing reducer is a three-stage cylindrical gear-enclosed heterosexual component. It is automatically lubricated with a screw lubricator. The air supply gyrator is composed of a connecting body, a seal, a hollow main shaft, and a drill pipe joint. There is a pneumatic clamp for connecting and unloading drill rods. Contact us to get the drilling machine’s price right now.

Lifting Pressure Regulating Mechanism

The lifting pressure regulating mechanism is realized by the lifting motor the lifting reducer, and the lifting chain. And the turning mechanism and the drilling tool. In the closed chain system, a pressure-regulating cylinder and a movable pulley block are installed. During normal operation, the piston rod of the pressure regulating cylinder pushes the movable pulley block to realize the decompression drilling of the strata drilling rig. Just leave your requirements, and we will reply to you within 12 hours.

Other Products

YG Machinery has a variety of drilling rigs for sale. For example, down-the-hole drilling rigs machine, water well drilling rigs, small water well drilling machines, portable water well drilling rigs, truck mounted water well drilling rigs, anchor rigs, crawler drill rigs, core drill rigs, horizontal directional drilling rigs, rotary drilling rigs, etc. Now contact us to get the drilling rigs price list. Contact us now.