The latex balloon making machine adopts the method of continuous production and direct dipping to produce natural latex toy balloons. The latex balloon is made of 100% pure natural latex. The latex material has high strength, high elasticity, and uniform thickness, and can keep nitrogen for a long time. The latex balloon making machine contains much equipment to make latex balloons, it is also called the latex balloon production line. The latex production line can produce balloons of various colors at the same time, with fully automatic dipping, demoulding, high output, and no sag.

Parameters of Latex Balloon Making Machine

| ITEM | Machine Length | 60m | 70m | 80m | 100m | 120m |

| 1 | Machine size(L*W*H)m | 60×1.4×4.5 | 70×1.4×4.5 | 80×1.4×4.5 | 100×1.4×4.5 | 120×1.4×4.5 |

| 2 | weight | 60T | 70T | 80T | 100T | 120T |

| 3 | Container | 6 | 7 | 8 | 10 | 12 |

| 3 | Workshop (L*W*H) | 80×4.5×5.7 | 90×4.5×5.7 | 100×4.5×5.7 | 120×4.5×5.7 | 120×4.5×5.7 |

| 4 | Capacity(24H) | 1T | 1.5T | 2T | 2.5T | 3T |

| 5 | Workers | 5 | 5 | 6 | 7 | 7 |

| 6 | Power(KW) | 65 | 70 | 75 | 90 | 100 |

| 7 | Water(ton) | 25 | 30 | 40 | 50 | 60 |

| 8 | natural Gas consumption(m³) | 700 | 1000 | 1400 | 1600 | 1800 |

| 9 | Usage of Latex(ton) | 1.7 | 2.5 | 3.4 | 4.1 | 5 |

The above are the parameters of the automatic latex balloon machine. You can choose the right machine model by output. Yugong provides 1t, 1.5t, 2t, 2.5t, and 3t latex balloon manufacturing machines. Check the above parameters and choose the machine that suits your production capacity.

Related: How to Start a Balloon Manufacturing Business?

Is the Balloon Production Project Profitable?

Automatic Latex Balloon Production Machine Advantages

- Use natural latex to produce balloons, which can be degraded and will not pollute the environment.

- The entire latex balloon production line adopts direct immersion continuous production, with a high degree of automation, and can produce balloons of various colors at the same time.

- Yugong provides a variety of latex balloon making machines to meet customers’ production of balloons of different volumes and sizes.

- The entire production line is designed according to the natural latex curing molding process, the process is reasonable, and the product is stable.

- The drying system adopts the principle of hot air circulation, the temperature in the drying room is uniform, and the balloon is heated evenly.

- The equipment mold connects by a specially designed elastic piston mold, which makes it easier to replace the mold.

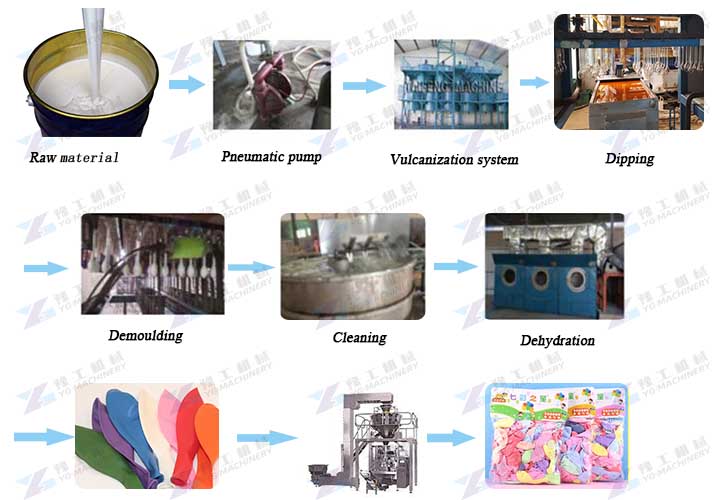

Latex Balloon Production Process

The production process of latex balloons is rough as follows:

- Prepare the raw materials for balloon production;

- Similar to the production of latex gloves, natural latex needs to be vulcanized to improve its properties of latex;

- After vulcanization, use a balloon dipping machine to dip the mold;

- After dipping, latex will be formed on the balloon mold, and it will be demolded after drying and cooling;

- Use the cleaning equipment to clean the produced balloon after demolding;

- In order to ensure that the drying time of the balloon surface is shortened, it is usually necessary to use an automatic dryer to dry the balloon;

- After cleaning and drying, you can use the balloon packaging machine for packaging, and then put it into the market for sale.

Finished Product Display

Application Place

Balloons are usually used as decoration to create a festive, warm and romantic atmosphere. The balloons produced by the latex balloon making machine can be used in various event venues. Such as birthday parties, main events, wedding celebrations, opening ceremonies, various festival scenes, etc.

Yugong balloon manufacturing machine manufacturer not only provides latex balloon making machines, but also aluminum foil balloon making machines. If you are interested in our balloon production machines, please leave us a message.