YG PSA oxygen generator price

YG Machinery Co., Ltd. has always been based on serving customers, focusing on technological innovation and energy efficiency improvement. And the continuous breakthrough optimization design, the never-stop pursuit of quality. This gives YG energy-saving oxygen generators such excellent qualities as stable, reliable, efficient production, energy-saving, and environmental protection. The technical level of the YG oxygen generator is in the leading position in the industry. If you need to buy a PSA oxygen generator, please feel free to contact the YG PSA oxygen generator manufacturer to get the PSA oxygen generator price.

The parameters of the 50Nm³/h and 100Nm³/h oxygen generators are listed below. If you need other oxygen production medical or industrial PSA oxygen generators, please feel free to contact us. Email: admin@yugongengineering.com

50Nm³/h oxygen generator machine specification

| Item | Parameters |

| Oxygen production | ≥50Nm³/h |

| Oxygen purity | ≥93±3% |

| Oxygen outlet pressure | 0.4MPa(Adjustable) |

| Oxygen Dew Point | —30℃(Normal pressure) |

| Oxygen temperature | ≤45℃ |

| Working pressure | ≥0.6MPa |

| Oxygen oil content | ≤0.003ppm |

| Oxygen dust particle size | ≤0.1um |

| System pressure difference | ≤0.1MPa |

| Raw material air consumption | ≥12Nm³/min(Average air consumption) |

| Raw material air dew point | ≤-10℃ |

| Control system | PLC auto-control |

| Load range | 30-100% |

| Max. pressure loss | ≤0.17MPa |

| Noise | ≤80db(A) |

100Nm³/h oxygen generator specification

| Project name | Parameters |

| Type of equipment | SPO93-100/4 |

| Oxygen production | 100NM³/h |

| Oxygen purity | ≥93% |

| Oxygen Dew Point | ≤-40℃ |

| Working pressure | 0.8MPa |

| Treatment Medium | Compressed air |

| Adsorption mode | Four-tower pressure swing adsorption |

| Oxygen outlet pressure | ≥0.5MPa |

| Start-up time | ≤30Min |

| Effective PSA gas consumption | ≥21.7NM3/min |

| Oxygen temperature | 24 ± 3℃ |

| Intake maximum oil content | ≤0.001ppm |

| Pressure drop | ≤0.05MPa |

| Residual oil dust content | ≤0.001ppm |

| Molecular sieve | The service life of 10 years |

| Pneumatic valve | Service life 3 million times |

| Compression mode | Cylinder compression |

| Container material | Carbon Steel (anti-rust blast) |

| Mode of discharge | Manual/automatic blowdown |

| Power supply | 220/60V/Hz |

| Power | 0.15KW |

| Mode of operation | Automaticity |

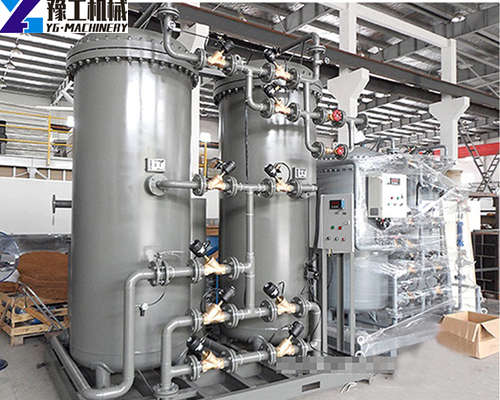

PSA oxygen generator system components

1) Air compressor — The power of the air compressor is selected according to the customer’s altitude. The higher the altitude, the greater the air compressor power.

2) Air storage tank — The size of the air buffer tank is related to the size of the air compressor model. Which is generally included in the air compressor.

3) Cold dryer — this is also configured according to the size of the oxygen generator and is generally included in the oxygen generator.

4) Air buffer tank — The size of the air buffer tank is related to the size of the oxygen concentrator. And it is generally included in the oxygen concentrator.

5) Oxygen concentrator — This is related to oxygen purity according to the model of the oxygen concentrator.

6) Oxygen buffer tank — The size of the oxygen buffer tank is related to the size of the oxygen concentrator and is generally contained in the oxygen concentrator.

7) Oxygen storage tank — The size of this oxygen storage tank is related to the size of the oxygen concentrator model. Which is generally included in the oxygen concentrator.

8) Booster — If the customer can discharge the pipeline by himself, there is no need to connect the oxygen cylinder and the booster is not needed. The size of the booster is related to the number of kilograms (optional).

9) Confluence pipe — related to the size of the booster, usually sold together with the booster. The price can be listed separately. If you don’t need a booster, you don’t need to write a separate manifold.

How to get an accurate PSA oxygen generator price?

If you want to get an accurate PSA oxygen generator price, please tell us the following questions.

1) How big a cubic oxygen generator do you need?

2) What is your local voltage and hertz?

3) What is the altitude of your local country?

4) Do you need an oxygen-filled cylinder?

5) What are your requirements for superchargers? 150bar or 200bar?

6) Do you need a containerized oxygen concentrator or in bulk?

Working principle of the PSA oxygen concentrator

PSA oxygen generator means Pressure Swing Adsorption oxygen generator. The separation air of the PSA oxygen generator is mainly composed of two adsorption towers filled with a sieve. Under normal temperature conditions, the compressed air is filtered, dewatered and dried, and then enters the adsorption tower. In the adsorption tower, the nitrogen in the air is absorbed by the molecular sieve. And the oxygen is enriched in the gas box.

Then it flows out from the outlet and is stored in an oxygen buffer tank. While the molecular sieve that has been adsorbed in another tower is quickly depressurized. And the adsorbed components are resolved. The two towers are cycled alternately to obtain oxygen with a purity of ≥90%. The automatic valve switching of the entire system is automatically controlled by a computer. Contact Us to get the PSA oxygen generator price for your reference.

PSA oxygen generator workflow

PSA oxygen generator work process as the following steps.

Left suction

After being compressed by an air compressor, the air enters the air storage tank after dust removal, oil removal, and drying. Then it enters the left adsorption tower through the air intake valve and the left intake valve. And the tower pressure increases. Then the nitrogen molecules in the compressed air are adsorbed by the zeolite molecular sieve. The unadsorbed oxygen passes through the adsorption bed and enters the oxygen storage tank through the left gas production valve and the oxygen gas production valve. This process is called left suction, and the duration is tens of seconds. If you are looking for a PSA oxygen generator price, please send your requirement to us now.

Pressure equalization

After the left suction process is over, the left adsorption tower and the right adsorption tower are connected through a pressure-equalizing valve to balance the pressure of the two towers. This process is called equalization, and the duration is 3 to 5 seconds.

Right suction

After the pressure equalization is over, the compressed air enters the right adsorption tower through the air intake valve and the right intake valve. Nitrogen molecules in compressed air are adsorbed by the zeolite molecular sieve. The enriched oxygen enters the oxygen storage tank through the right gas production valve and the oxygen gas production valve. This process is called right suction, and the duration is tens of seconds. As one of the professional PSA oxygen generator manufacturers, YG has high quality & cheap PSA oxygen generator prices for you all the time.

Desorption

At the same time, the nitrogen adsorbed by the zeolite molecular sieve in the left adsorption tower is released back into the atmosphere through the left exhaust valve. This process is called desorption. On the contrary, when the left tower is adsorbing, the right tower is also desorbing at the same time.

Backflushing

In order to completely discharge the nitrogen released by the depressurization of the molecular sieve into the atmosphere. The oxygen gas passes through a normally open back-purge valve to purge the desorption adsorption tower. And the nitrogen in the tower is blown out of the adsorption tower. This process is called backflushing, and it is carried out simultaneously with desorption.

After the right suction is finished, it enters the pressure equalization process. Then switches to the left suction process and continues to continue. So as to continuously produce high-purity product oxygen.

Installation site requirements

- The installation site should be clean, level, easy to reach by crane or forklift, and capable of installation. The height of the installation workshop and the ground load must meet the requirements. The installation area should not be less than the drawings provided by the supplier. And appropriate maintenance space should be reserved.

- The ambient temperature of the installation site is 0-40℃, the relative humidity is 35-90%, and the altitude is ≤4300 meters.

- The ambient air around the installation site should be clean, free of strong acid and alkali air, and corrosive gases. Because certain chemical substances are serious to carbon molecular sieve. It is easy to cause carbon molecular sieve poisoning. The plant should be well ventilated.

- The on-site power supply and voltage must meet the requirements, and the voltage fluctuation cannot exceed ±10% of the rated voltage.

Customer Cases

With reliable quality and extremely competitive prices, our oxygen production equipment is for sale to many countries and regions. This includes India, Myanmar, Vietnam, Philippines, Singapore, Indonesia, Thailand, and other Southeast Asian countries. Mongolia, Saudi Arabia, Oman, and other Asian countries. Peru, Mexico, Brazil, and other South American countries. South Africa, Tanzania, Morocco, Algeria, Kenya, Tanzania, Uganda, Rwanda, and other African countries. And the United States, Kazakhstan, Argentina, Chile, and other countries and regions.

Click here to know about some of our customer cases. Medical Oxygen Generator For Sale In India. Oxygen Generator Machine For Sale in Myanmar. Medical Oxygen Concentrator For Sale in Peru. PSA Oxygen Generator VS VPSA Oxygen Generator.