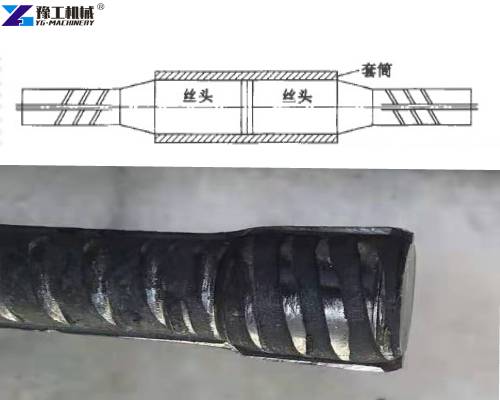

Do you often see the following connection methods in construction projects? This is called the steel upsetting casing connection method. In the field of construction, the steel joints have always been the weakest parts. After continuous exploration and development, the connection technology of steel upsetting sleeves has gradually matured. This connection technology is not only widely used in the construction industry, but also in many industries such as bridges and high-speed rail. Do you want to know what is steel upsetting sleeve connection technology and what advantages does it have?

What is steel upsetting connection technology?

The steel upsetting coulper connection technology is to first use a steel upsetting machine to upsetting the tail end of the steel bar. The diameter of the end of the steel bar after upsetting is increased. Then use the rebar threader to roll the upsetting section of the rebar, and then use the sleeve to connect the upsetting and rolling rebar sections. At this point, the steel upsetting sleeve connection is completed. The steel upsetting straight thread connection technology has extremely high stability, and the strength of the joint is greater than that of the original steel bar. Therefore, this connection technology is usually used for the connection of steel cages for bridges, high-speed railways, etc.

Upset forging advantages

Compared with the common steel bar thread connection technology, the steel bar upsetting connection technology is first upsetting, and then connected after threading.

Therefore, compared with the common connection technology, the upsetting sleeve connection technology has the characteristics of high strength, fast connection speed, wide application range and stable performance.

1. High connection strength. The upsetting steel bar not only increases the cross-sectional area of the end, but also the strength of the joint is higher than that of the base material of the steel bar after cold heading.

2. Fast connection speed. When connecting, just put the sleeve on the steel bar and tighten it with a wrench. There is no need to use screws for fixing, which greatly reduces the labor intensity and shortens the connection time.

3. Wide range of application. Rebar connection sleeve technology can be used in places where rebars are bent and cannot be rotated, and can also be used in small spaces.

4. Stable performance. The steel upsetting wire can be directly processed on site. The connection can be made under various weather conditions during construction connection. It is also suitable for special construction environments such as underwater and flammable.

Yugong provides high-quality steel upsetting machines

As a Chinese construction machinery supplier, Yugong offers a variety of steel bar handling machinery. Among them, the steel upsetting machine is more popular with customers. Yugong provides two types of steel upsetting machines, single-cylinder and double-cylinder, which can process steel bars with a diameter of 16-40mm. The processed steel bar can be upsetting by 3~5mm. At present, the steel bar upsetting machine of Yugong has been widely used in

National key projects such as buildings, roads and bridges, high-speed railways, subways, tunnels, and power stations. In addition, Yugong Machinery also provides steel bar cutting machines, steel bar bending machines, steel bar straightening and cutting machines, cold bending machines and other steel bar processing equipment. If you need rebar handling equipment, please leave a message below.