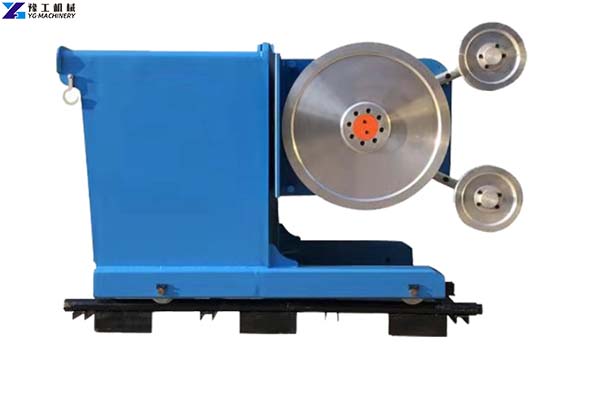

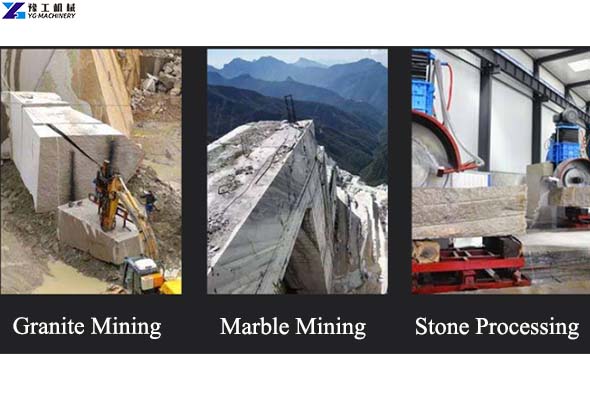

The diamond wire saw machine for granite is equipment for mining and processing marble and granite mine blocks. Therefore, this equipment is also called a marble wire saw machine and a granite wire saw machine. The quarry wire saw machine is not limited by the size of the stone, and can cut in any direction, such as horizontal, vertical, and diagonal directions. Using this equipment can cut stone products with a smooth cutting surface, neat cutting edge, precise processing surface contour, and standard size. YG provides various types of marble or granite wire saw machines for sale. Please check the detailed mine wire saw machine parameters below.

3 Kinds of Quarry Wire Saw Machines Introduction

YG offers three types of wire saw machines for mining, wire saw machines for marble mines, wire saw machines for granite mines, and power-saving wire saw machines. The following is a detailed introduction to the situation and parameters of the three diamond wire saw machines. YG also supplies the track wire saw machine, hydraulic wall saw, and concrete wall cutting machine. If you are interested in the equipment, please contact us.

Marble Diamond Wire Saw Machine

Quarry wire saw machine has been widely used in stone mining. Due to the color of the marble, the texture will change, and the wire saw machine for granite can avoid discoloration and cracks for mining. And it is also suitable for mining and processing marble with different hardness. The mining depth of this equipment can reach 10-20 meters, reducing waste, strong function, and high efficiency. Use the mine wire saw machine to make the cutting surface smooth and smooth without internal damage, and the sawing kerf is small. The equipment can realize 360° rotation and can realize cutting in different directions such as horizontal, vertical, and inclined according to cutting requirements.

Diamond Wire Saw for Marble Parameters

| Model | LKH22-6 | LKH37-6 | LKH45-6 | LKH55-6 | LKH75-6 |

| Total Power(kW) | 26 | 41 | 49 | 59 | 79 |

| Main Motor Power (kW) | 22 | 37 | 45 | 55 | 75 |

| Main motor rated speed(RPM) | 980 | 980 | 980 | 980 | 980 |

| Main flywheel diameter(mm) | 600 | 700 | 800 | 800 | 800 |

| Wire saw line speed(m/s) | 0-35 | 0-40 | 0-40 | 0-40 | 0-40 |

| Length of rope(M) | 20-60 | 20-80 | 20-100 | 20-120 | 20-150 |

| Walking motor power(kW) | 0.55 | 0.75 | 0.75 | 1.1 | 1.5 |

| Traverse distance(MM) | 1500 | 1800 | 1800 | 2000 | 2200 |

| Rotation angle | 360° | 360° | 360° | 360° | 360° |

| Machine walking speed(m/h) | 0-40 | 0-40 | 0-40 | 0-40 | 0-40 |

| Track length | 2M*3 | 2M*4 | 2M*4 | 2M*4 | 2M*4 |

| Permissible temperature(℃) | ~15~+40 | ~15~+40 | ~15~+40 | ~15~+40 | ~15~+40 |

| Machine Weight(T) | 1.5 | 2.4 | 2.6 | 3.3 | 3.8 |

| Oversize(cm) | 156*110*126 | 185*120*130 | 185*120*130 | 200*130*135 | 215*140*136 |

Diamond Wire Saw Machine For Granite

Granite is harder than marble, so it is generally cut with a high-power wire saw. The diamond wire saw machine for granite is controlled by PLC for wire saw tension and cutting current. It can precisely control the cutting process by setting parameters, has manual and automatic functions, and is easy to operate.

Granite Wire Saw Machine Parameters

| Model | LKH22-8 | LKH37-8 | LKH45-8 | LKH55-8 | LKH75-8 |

| Total Power(kW) | 26 | 41 | 49 | 59 | 79 |

| Main Motor Power (kW) | 22 | 37 | 45 | 55 | 75 |

| Main motor rated speed(RPM) | 740 | 740 | 740 | 740 | 740 |

| Main flywheel diameter(mm) | 600 | 700 | 800 | 800 | 800 |

| Wire saw line speed(m/s) | 0-35 | 0-40 | 0-40 | 0-40 | 0-40 |

| Length of rope(M) | 20-60 | 20-80 | 20-100 | 20-120 | 20-150 |

| Walking motor power(kW) | 0.55 | 0.75 | 0.75 | 1.1 | 1.5 |

| Traverse distance(MM) | 1500 | 1800 | 1800 | 2000 | 2200 |

| Rotation angle | 360° | 360° | 360° | 360° | 360° |

| Machine walking speed(m/h) | 0-40 | 0-40 | 0-40 | 0-40 | 0-40 |

| Track length | 2M*3 | 2M*4 | 2M*4 | 2M*4 | 2M*4 |

| Permissible temperature(℃) | ~15~+40 | ~15~+40 | ~15~+40 | ~15~+40 | ~15~+40 |

| Machine Weight(T) | 1.5 | 2.4 | 2.6 | 3.3 | 3.8 |

| Oversize(cm) | 156*110*126 | 185*120*130 | 185*120*130 | 200*130*135 | 215*140*136 |

New Power Saving King Wire Saw Machine

The new energy-saving wire saw machine adopts the latest permanent magnet synchronous motor and permanent magnet synchronous drive technology, which saves electricity very much. Compared with ordinary wire saw machines for granite, it can save more than 20% of electricity. Compared with asynchronous motors, permanent magnet synchronous motors have lower calorific value, smaller size, lower failure rate, and longer service life.

| Model | SDW37/6 | SDW45/6 | SDW55/6 | SDW75/6C |

| Total Power(kW) | 41 | 49 | 59 | 79 |

| Main Motor Power (kW) | 37 | 45 | 55 | 75 |

| Main motor rated speed(RPM) | 1000 | 1000 | 1000 | 1000 |

| Main flywheel diameter(mm) | 700 | 800 | 800 | 800 |

| Wire saw line speed(m/s) | 0-40 | 0-40 | 0-40 | 0-40 |

| Length of rope(M) | 20-80 | 20-100 | 20-120 | 20-150 |

| Walking motor power(kW) | 0.75 | 0.75 | 1.1 | 1.5 |

| Traverse distance(MM) | 1800 | 1800 | 2000 | 2200 |

| Rotation angle | 360° | 360° | 360° | 360° |

| Machine walking speed(m/h) | 0-40 | 0-40 | 0-40 | 0-40 |

| Track length | 2M*4 | 2M*4 | 2M*4 | 2M*4 |

| Permissible temperature(℃) | ~15~+40 | ~15~+40 | ~15~+40 | ~15~+40 |

| Machine Weight(T) | 2.2 | 2.3 | 2.6 | 3.3 |

| Oversize(cm) | 185*120*130 | 185*120*130 | 185*120*130 | 200*130*135 |

Why Use a Quarry Wire Saw Machine?

The ancient quarrying method is generally mining by blasting, which not only seriously damages the environment, but also causes a waste of resources. Therefore, the most commonly used mining method at present is to use a quarry wire saw machine. The wire saw machine for marble granite can cut in any direction without being limited by the size of the stone. Moreover, the cutting surface of the stone cut by this equipment is smooth, the cutting edge is neat, and the contour of the processing surface is precise. These advantages are very widely used with mining wire saw machines.

Features of Diamond Mine Wire Saw Machine for Granite

- Wide range of applications. It can not only be used to mine marble, granite, etc. but also can be used with other devices for trenching, separation, shaping, disintegration, etc.

- The mining depth is deep, the cutting speed is fast, the machine body can realize 360° rotation, and can cut in various directions such as vertical and horizontal.

- The high degree of automation, simple and direct operation interface, easy to operate and master, realize automatic control of the cutting process.

- Safety and environmental protection, no noise, no dust, separate control, and the low labor intensity of workers.

- Strong function, high efficiency, mining depth can reach 10~20m or even deeper. Fast cutting speed, up to 3~4㎡/h.