The mining drilling equipment uses wireline coring diamond drilling techniques to drill holes for coring. The modified equipment is the leading model for solid deposit exploration. The full hydraulic core sample drilling rig is widely used in geology, metallurgy, coal, oil, natural gas, groundwater, and other industries. It can be used in geology exploration, hydrological surveys, oil and gas field exploration, water well drilling, etc.YG offers various mineral exploration drilling rigs for sale, please contact us for more quotations.

What is a Mining Drilling Equipment?

The mining drilling equipment mainly applies to geological, mineral, coal, petroleum, and other exploration and drilling equipment. Drilling rigs used for geological exploration include core drilling rigs, water source drilling rigs, prospecting drilling rigs, etc. The core drilling rig adopts mechanical transmission, a simple structure, and easy maintenance and operation.

Fully Hydraulic Core Sample Drilling Rig Application

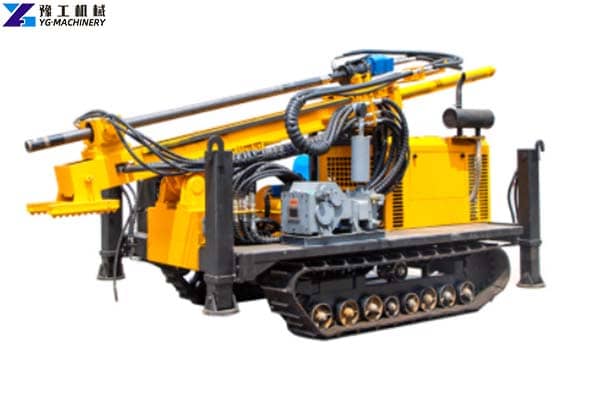

The fully hydraulic crawler core sample drilling rig is suitable for various drilling techniques such as diamond wireline core drilling, impact rotary drilling, directional drilling, and reverse circulation continuous core drilling. Not only that, but it can also be used for water well drilling, anchor drilling, engineering geological drilling, and other constructions.

Why Use Core Drilling Machine for Mining?

In resource exploration, it is necessary to obtain physical rock ore samples from the underground environment, and drilling technology is required. Due to the continuous acceleration of resource exploration and mining construction, coupled with the complex geology and hydrological environment of the mining area, the original technology can no longer meet the demand. The core drilling machine for mining has a vertical shaft with a through hole diameter of up to 100mm, and double oil cylinder hydraulic feed, which is especially suitable for wireline core drilling with large diameter drill pipes.

The use of mineral exploration drilling rigs is conducive to improving drilling efficiency and reducing accidents in holes. Moreover, its drilling capacity is large, and its crawler structure is suitable for various geological conditions. The installation is simple, convenient, and practical, the oil temperature of the hydraulic system is low, and the work is stable. Therefore, it is not only suitable for alloy and diamond core drilling, but also for engineering geological surveys, hydrological water well drilling, and foundation pile engineering construction.

Advantages of Mining Drilling Machine

The crawler fully hydraulic mining drilling machine adopts the rope coring method, which is suitable for mining exploration sampling and pre-exploration geological coring. Wireline sampling technology has a wide range of applications, strong operability, and high accuracy of exploration results. The wireline coring slewing mechanism does not need to transmit the impact force, and it is more convenient to use the wire rope to pull the core of the inner tube. Moreover, the drilling efficiency of wireline coring is high, and the drilling depth is low, which can ensure the quality of the core.

Full Hydraulic Core Sample Drilling Rig Parameters

| Model | Model | YDX-400 | YDX-600 | YDX-800 | YDX-1000 |

| Drilling capacity | Drilling depth | 180-400-500(M) | 200-600-650(M) | 400-800-1000(M) | 500-1000-1100(M) |

| Hydraulic system | Limited Data | 168(L/min) | 192(L/min) | 260(L/min) | 300(L/min) |

| Cooling method | Air cooling + water cooling | Air cooling + water cooling | Air cooling + water cooling | Air cooling + water cooling | |

| Engine | Engine type | Turbocharged | Turbocharged | Turbocharged | Turbocharged |

| Rated speed | 2400(RPM) | 2400(RPM) | 2400(RPM) | 2400(RPM) | |

| Rated power | 78kw | 92kw | 92kw(six-cylinder) | 154kw(six-cylinder) | |

| Power Head | Maximum torque | 300-500(N.M) | 450-1000(N.M) | 950-1300(N.M) | 1000-3500(N.M) |

| Maximum speed | 1300(RPM) | 1300(RPM) | 1300(RPM) | 1300(RPM) | |

| Give the process | 1900(MM) | 1900(MM) | 2400(MM) | 3500(MM) | |

| Pylon | Drilling angle | 0-90° | 45-90° | 45-90° | 45-90° |

| Lifting Force | 12T | 16T | 24T | 30T | |

| Feed force | 6T | 8T | 12T | 15T | |

| Winch | Lifting Force | 500KG | 600KG | 600KG | 1000KG |

| Rotating speed | 100-240(RPM) | 100-300(RPM) | 100-300(RPM) | 100-300(RPM) | |

| Wire rope diameter | 6(MM) | 6(MM) | 6(MM) | 6(MM) | |

| Capacity | 500(M) | 600(MM) | 800(MM) | 1000(MM) | |

| Walk | Walking speed | 2.5(KM/H) | 3.5(KM/H) | 3.5(KM/H) | 3.5(KM/H) |

| Stand-alone climbing angle | 45° | 45° | 45° | 45° | |

| Hydraulic mud pump | Flow | 30-90(L/MIN) | 30-90(L/MIN) | 90-180(L/MIN) | 90-180(L/MIN) |

| Pressure | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) | 4-7(MPA) | |

| Machine Size | 4000*1900*1800(MM) | 4000*2000*1800(MM) | 5500*2100*2000(MM) | 6000*2200*2400(MM) | |

| Weight | 4.3T | 4.5/5.5T | 6.5T | 7.5T |

The above are the parameters of the full hydraulic crawler core drilling rig, you can choose the appropriate type of equipment according to your needs. In addition, YG also provides water well drilling rigs, horizontal directional drilling machines, crawler drill rigs, diamond core drilling rigs, Rotary Drilling rigs, etc.

Full Hydraulic Crawler Mining Drilling Equipment Details

A full hydraulic transmission system

Realize the integration of machine, electricity, and hydraulic, stable transmission, centralized operation, stability, and reliability.

Rig hydraulic system

The load-sensitive control system is adopted to fully optimize the design of the hydraulic transmission system and control system to control construction costs.

Power Head

The power head gearbox has step-less speed regulation and a wide speed range, which is suitable for various drilling processes and different drilling diameters for speed and torque requirements.

Drill pipe clamping

Equipped with hydraulic chuck and hydraulic clamp to clamp the drill pipe. By replacing the slips, it can hold various specifications of rope core drilling rigs, with large diameters, and is easy to use.

Imported hoist

Equipped with an imported hoist, step-less speed regulation, rope coring hydraulic winch with stepless speed regulation, wide speed range, and flexible operation. The mast can be lifted and lowered by an oil cylinder to slide as a whole, and it can be drilled within the range of 0-90°.

Crawler Mining Drilling Machine Features

- The power head moves to the left automatically

- Equipped with an imported hoist, the mast of the hoist is automatically raised, and the speed is steplessly regulated

- Drilling depth 500-1000m

- Drilling at any angle from 45° to 90°

- Fast drilling, high drilling precision, and sufficient power

- YG matches a variety of supporting drill bits and drilling tools, with high drilling accuracy and a core removal rate of up to 99%.

- A variety of hydraulic exploration core drilling rigs are available to meet the exploration needs of different customers

- Suitable for coring and exploration of various complex geology

- Full hydraulic transmission, stable transmission, low noise, convenient and labor-saving, stable and reliable

- The hydraulic system adopts a load-sensitive control system and fully optimizes the design of the hydraulic transmission system and control system, and the construction cost is low.