The paper bag making machine is a general term for machines that make paper bags. There are two types of paper bag machines: square paper bag machines and V-bottom paper bag machines. The paper bag machine has two models semi-automatic and fully automatic, which can make square-bottom or V-bottom paper bags from primary color paper or printed roll paper at one time. Square-bottom paper bag machines can also make paper bags with or without knots. The paper bags made by this paper bag machine can be used as shopping bags, kraft paper bags, ultra paper bags, carry bags, paper courier bags, grocery paper bags, and food paper bags.

Paper Bag Display

Why is Paper Bag Making Machine Popular?

Modern increasingly advocate the concept of environmental protection and economic development. Therefore, many shopping bags, handbags, coffee cups, etc. are gradually replaced by non-degradable materials such as plastics and other non-degradable materials. Under this development trend, environmentally friendly paper bags are bound to be more and more favored by the government, shops, and consumers in the future. Therefore, paper bag machines for making environmentally friendly and degradable paper bags are becoming more and more popular.

Types of Paper Bag Machines

According to the types of paper bags produced, paper bag machines can be divided into V-bottom paper bag machines and square-bottom paper bag machines. V bottom paper bag-making machine is mainly used to produce V bottom paper bags without knots. The square bottom paper bag machine can produce square bottom paper bags, which can produce square bottom paper bags with knots or square bottom paper bags without knots. Paper bags with knots can use either braided knots or raw rope knots.

Square paper bag machine

Semi-automatic 220 square paper bag machine

| Model | YG-220 |

| Cutting Length | 190-330mm |

| Paper Bag Width | 220mm |

| Bottom width | 50-105mm |

| Paper bag thickness | 50-130g/㎡ |

| Mechanical speed | 30-260pcs/min |

| Paper bag speed | 30-200pcs/min |

| Paper roll width | 280-640mm |

| Paper diameter | 1300mm |

| The inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 11.5kw |

semi-automatic 350

| Model | YG-350 |

| Cutting Length | 270-530mm |

| Paper Bag Width | 120-350mm |

| Bottom width | 60-150mm |

| Paper bag thickness | 60-150g/㎡ |

| Mechanical speed | 30-220pcs/min |

| Paper bag speed | 30-180pcs/min |

| Paper roll width | 380-1050mm |

| Paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 15kw |

| The whole machine pressure | 0.5MPa-0.8MPa |

| Total Weight | 8500kg |

| Overall size | 10000*3700*2200mm |

semi-automatic 450

| Model | YG-450 |

| Cutting Length | 270-530mm |

| Paper Bag Width | 210-450mm |

| Bottom width | 90-180mm |

| Paper bag thickness | 80-150g/㎡ |

| Mechanical speed | 30-220pcs/min |

| Paper bag speed | 30-150pcs/min |

| Paper roll width | 660-1290mm |

| Paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 380V 3phase 4line 15kw |

| The whole machine pressure | 0.5MPa-0.8MPa |

| Total Weight | 9000kg |

| Overall size | 10000*3800*2200mm |

full automatic 220 paper bag making machine

| Model | YG-220T |

| Cutting Length(total) | 230-370mm |

| Paper Bag Width(total) | 140-220mm |

| Bottom Width | 60-140mm |

| Paper gsm(total) | 50-140g/㎡ |

| Material Width(total) | 410-770mm |

| Paper Material Diameter | 1300mm |

| Paper Core Inner Diameter | 76mm |

| Handle Patch Length | 152mm |

| Handle Patch Width | 50mm |

| Paper Rope Spacing | 75mm |

| Paper Handle Rope Diameter | 3-5mm |

| Handle Patch Paper Roll Width | 100mm |

| Handle Paper Roll Diameter | 1200mm |

| Handle Patch Paper Weight | 100-135g/㎡ |

| Mechanical Speed | 30-200pcs/min |

| Paper Bag Production Speed | 30-18pcs/min |

| Handle Speed | 30-150pcs/min |

| Cutter Method | Pinking |

| Total Power | 380V/ 3Phase 4Line 28kw |

| The whole machine pressure | 0.6-0.7MPa |

fully automatic 350

| Model | YG-350T |

| Cutting Length | 270-530mm |

| Cutting Length(total) | 270-430mm |

| Paper Bag Width | 120-350mm |

| Paper Bag Width(total) | 200-350mm |

| Bottom Width | 60-150mm |

| Paper gsm | 60-150g/㎡ |

| Paper gsm(total) | 80-150g/㎡ |

| Material Width | 380-1050mm |

| Material Width(total) | 570-1050mm |

| Paper Material Diameter | 1300mm |

| Paper Core Inner Diameter | 76mm |

| Handle Patch Length | 152mm |

| Handle Patch Width | 50mm |

| Paper Rope Spacing | 75mm |

| Paper Handle Rope Diameter | 3-5mm |

| Handle Patch Paper Roll Width | 100mm |

| Handle Paper Roll Diameter | 1200mm |

| Handle Patch Paper Weight | 100-135g/㎡ |

| Mechanical Speed | 30-200pcs/min |

| Paper Bag Production Speed | 30-180pcs/min |

| Handle Speed | 30-150pcs/min |

| Cutter Method | Pinking |

| Total Power | 380V/ 3Phase 4Line 41.5kw |

| The whole machine pressure | 0.5-0.8MPa |

| Total Weight | 15000Kg |

| Machine Overall Dimension | 14000*6000*2400mm |

fully automatic 450

| Model | YG-450T |

| Cutting Length | 270-530mm |

| Cutting Length(total) | 270-430mm |

| Paper Bag Width | 220-450mm |

| Paper Bag Width(total) | 240-450mm |

| Bottom Width | 90-180mm |

| Paper gsm | 80-150g/㎡ |

| Paper gsm(total) | 80-150g/㎡ |

| Material Width | 650-1290mm |

| Material Width(total) | 650-1290mm |

| Paper Material Diameter | 1200mm |

| Paper Core Inner Diameter | 76mm |

| Handle Patch Length | 190mm |

| Handle Patch Width | 50mm |

| Paper Rope Spacing | 95mm |

| Paper Handle Rope Diameter | 3-5mm |

| Handle Patch Paper Roll Width | 100mm |

| Handle Paper Roll Diameter | 1200mm |

| Handle Patch Paper Weight | 100-135g/㎡ |

| Mechanical Speed | 30-180pcs/min |

| Paper Bag Production Speed | 30-150pcsmin |

| Handle Speed | 30-130pcs/min |

| Cutter Method | Pinking |

| Total Power | 380V/ 3Phase 4Line 41.5kw |

| The whole machine pressure | 0.6-0.7MPa |

| Total Weight | 15500Kg |

| Machine Overall Dimension | 14000*6200*2400mm |

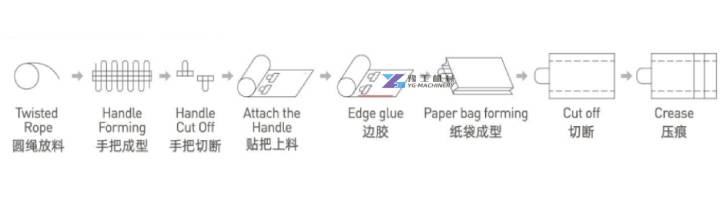

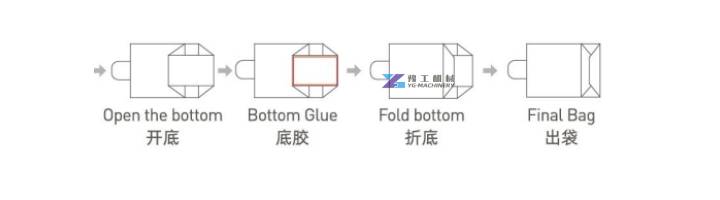

Paper Bag Making Process

The picture shows the production process of the square bottom paper bag with knots, the process of the square bottom paper bag without knots from feeding to the final. If you make a V-bottom paper bag, you need to replace the indentation position on the basis of the cordless knot square bottom machine to make it folded into a V-bottom.

How About the Paper Bag Machine Price?

The above is the introduction of paper bag making machine manufacturers for square or V-shaped paper bag machines. If you are interested in any one, please contact us. Because the machines used to produce different kinds of paper bags are different, and each paper bag machinery also has a variety of models. Therefore, the paper bag machines’ price is different. If you want to know the detailed price of the paper bag making machine, please let us know the size of the paper bag you want to make, whether it is a square bottom or a V bottom, and details such as with or without knots.

Other machines

Yugong also provides paper cup machine, water bottle filling machine, environmental protection machinery, prestressing equipment, rebar processing machine, concrete cutting machine, ect. If you are interested in the above machines, please feel free to contact YG engineering.