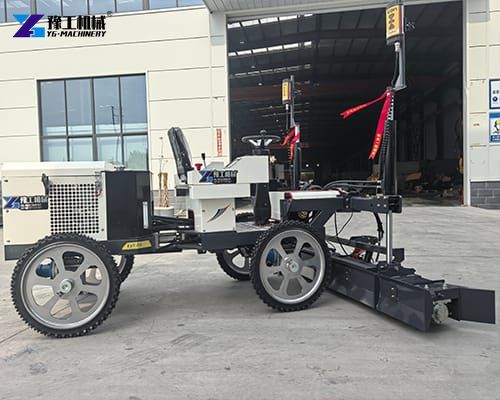

Laser concrete screed machine is a high-precision automated system designed to level concrete surfaces with exceptional accuracy. Compared to traditional manual methods that rely on string lines and human expertise, this machine uses laser technology to maintain consistent elevation across large floor pours. The system consists of a laser transmitter, receiver sensors, a hydraulically driven leveling head, and integrated vibrators. The laser transmitter emits a stable reference plane, while receivers on the screed head continuously adjust the machine’s position to maintain perfect alignment.

Parameters of the Laser Concrete Screed Machine

| Model | YG-CL300 | YG-CL300A |

| Engine model | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) |

| Engine type | Gasoline, air-cooled 4-stroke, twin-cylinder engine | Gasoline, air-cooled 4-stroke, twin-cylinder engine |

| Engine power | 22KW/30ps | 22.8KW/23ps/31ps |

| Fuel capacity | 20L (operation time is about 8 hours | 20L (operation time is about 8 hours |

| Hydraulic oil capacity | 37L | 35L |

| Laser transmitter | Swiss Leica/Tower transmitter (optional) | Swiss Leica/Tower transmitter (optional) |

| Laser receiver | Swiss Leica/Tower receiver (optional) | Swiss Leica/Tower receiver (optional) |

| Laser system control effect | Plane, slope, double slope (three-dimensional) | Plane, slope, double slope (three-dimensional) |

| Laser system control method | Microcomputer laser scanning | Microcomputer laser scanning |

| Paving method | Hydraulic stirring cage paving | Hydraulic stirring cage paving |

| Vibration method/excitation force | Hydraulic vibration/2000N | Hydraulic vibration/2000N |

| Vibration plate width | 2500mm | 3000mm |

| Leveling thickness | 50-300mm | 60-300mm |

| Travel drive | Reducer motor integrated | Reducer motor integrated |

| Travel speed | 0-4Km/h (speed adjustable) | 0-4Km/h (speed adjustable) |

| Travel tire | Solid anti-skid and anti-puncture tires (optional wide tires) | Solid anti-skid and anti-puncture tires (optional wide tires) |

| Body size | 3250x2850x1320mm | 3300x3460x1650mm |

Laser Concrete Screed Machine Features

- High precision control is one of its most important characteristics. Laser sensors constantly receive signals from the transmitter and convert them into precise height adjustments, eliminating human error.

- Automation is another defining element. Once parameters are set, the machine performs screeding, leveling, and compaction with minimal operator intervention, reducing labor intensity and fatigue.

- Large area efficiency allows the machine to complete thousands of square meters in a single day. This makes it especially suitable for expansive floor slabs.

- Consistency across the entire slab ensures uniform surface quality, preventing localized dips or high spots that can compromise structural or operational performance.

- Data-driven operation enables repeatability and reliability, even when operated by different personnel or under varying site conditions.

Core Components and Structural Design

The structural design of a laser concrete screed machine is engineered for robustness and precision. Key components include:

- Laser Transmitter: Positioned off-site, this device projects a 360-degree laser plane that serves as the elevation reference.

- Receiver Sensors: Mounted on the screed head, these sensors detect the laser signal and relay data to the control system.

- Leveling Head: Equipped with scrapers, vibrators, and augers, this unit levels, consolidates, and compacts the concrete simultaneously.

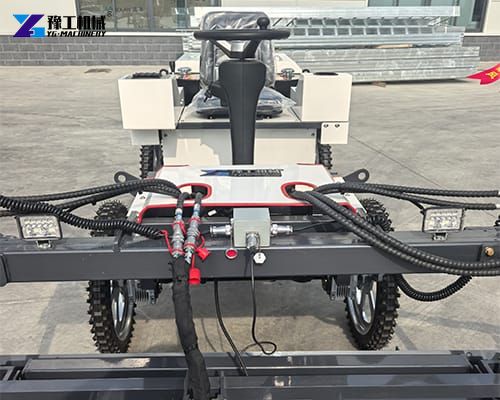

- Hydraulic System: Powers the machine’s movement and adjusts the screed height with millisecond precision.

- Control Unit: The brain of the system, it processes sensor data and adjusts hydraulic valves for real-time elevation control.

Main Applications of the Laser Concrete Leveling Machine

The laser concrete screed machine is widely used across multiple construction scenarios due to its versatility and performance.

- Industrial flooring applications include factories, workshops, and production plants where heavy machinery requires stable and level floors.

- Warehouse and logistics centers rely heavily on laser-screeded floors to support high rack storage systems and automated guided vehicles.

- Commercial buildings such as shopping malls, exhibition halls, and parking garages benefit from smooth, durable concrete surfaces.

- Infrastructure projects, including airports, ports, and railway facilities, use laser screeding to achieve large-scale flat concrete pavements.

- Residential developments with underground parking or large common areas also increasingly adopt this technology to improve build quality and speed.

Concrete Laser Leveling Machine Advantages

One of the most compelling reasons to use a laser concrete screed machine is the wide range of advantages it offers compared to traditional screeding techniques.

- Improved flatness and levelness result in superior floor performance and reduced need for corrective grinding or overlays.

- Higher construction efficiency shortens project timelines, allowing contractors to complete jobs faster and take on more work.

- Reduced labor costs are achieved because fewer workers are needed to perform screeding and leveling tasks.

- Lower material waste occurs due to precise control of concrete thickness, preventing overpouring.

- Enhanced durability of the finished floor minimizes cracking, uneven wear, and long term maintenance costs.

- Better working conditions improve safety and reduce physical strain on construction crews.

How to Choose the Right Machine?

Selecting the right laser concrete screed machine requires careful consideration of project needs and operational constraints.

- Project size is a key factor. Larger slabs benefit from machines with wider screed heads and higher output capacity.

- Surface tolerance requirements determine the level of precision needed, influencing sensor quality and control systems.

- Power source availability may affect the choice between diesel-powered and electric models.

- Mobility and maneuverability are important for sites with limited access or complex layouts.

- Budget considerations must balance initial cost against long-term efficiency and durability benefits.