Laser concrete leveling machine, also known as laser concrete screed, is a specialized equipment designed to automate the process of leveling and smoothing concrete surfaces. Different traditional methods that rely on manual labor and basic tools, these machines use laser technology to achieve unparalleled accuracy. The laser system emits a beam that serves as a reference point for the machine’s sensors, allowing it to adjust its height and angle in real time. This ensures that the concrete surface is perfectly flat and level, meeting the strictest standards for industrial, commercial, and residential projects.

Parameters of Laser Concrete Leveling Machine

| Model | YG-CL300 | YG-CL300A | YG-ZP30 |

| Engine model | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) | Yanmar 4TNV94L |

| Engine type | Gasoline, air-cooled 4-stroke, twin-cylinder engine | Gasoline, air-cooled 4-stroke, twin-cylinder engine | Diesel |

| Engine power | 22KW/30ps | 22.8KW/23ps/31ps | 35.5KW/48hp |

| Fuel capacity | 20L (operation time is about 8 hours | 20L (operation time is about 8 hours | 100L |

| Hydraulic oil capacity | 37L | 35L | 150L |

| Laser transmitter | Swiss Leica/Tower transmitter (optional) | Swiss Leica/Tower transmitter (optional) | Danfoss |

| Laser receiver | Swiss Leica/Tower receiver (optional) | Swiss Leica/Tower receiver (optional) | American Tempo |

| Laser system control effect | Plane, slope, double slope (three-dimensional) | Plane, slope, double slope (three-dimensional) | German Mopar |

| Laser system control method | Microcomputer laser scanning | Microcomputer laser scanning | Flat, inclined or double slope (3D) |

| Paving method | Hydraulic stirring cage paving | Hydraulic stirring cage paving | Microcomputer laser scanning |

| Vibration method/excitation force | Hydraulic vibration/2000N | Hydraulic vibration/2000N | Hydraulic Cage Paving |

| Vibration plate width | 2500mm | 3000mm | Hydraulic motor |

| Leveling thickness | 50-300mm | 60-300mm | Flip up and down for easy cleaning, left and right switching, blades made of highly wear-resistant material, more durable |

| Travel drive | Reducer motor integrated | Reducer motor integrated | 6000mm |

| Travel speed | 0-4Km/h (speed adjustable) | 0-4Km/h (speed adjustable) | 3100mm |

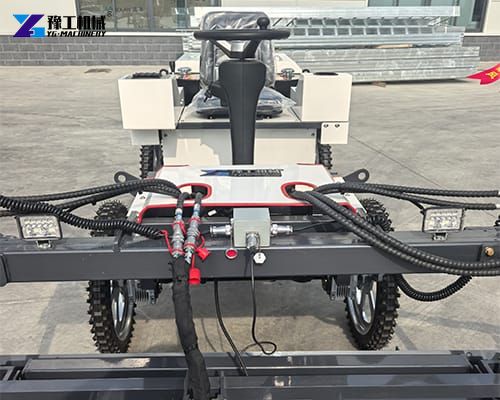

| Travel tire | Solid anti-skid and anti-puncture tires (optional wide tires) | Solid anti-skid and anti-puncture tires (optional wide tires) | 100-450mm |

| Body size | 3250x2850x1320mm | 3300x3460x1650mm | 4-8km/h 24m/min |

Features of Advanced Laser Leveling Equipment

- Precision Control Systems

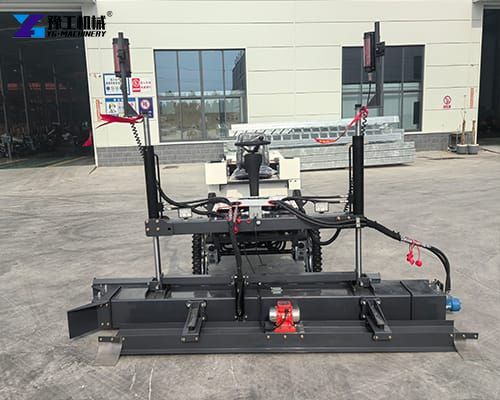

The heart of the machine is its laser control system. It consists of a stationary laser transmitter and receivers mounted on the machine. This ensures that the screed head stays at the exact elevation required, compensating automatically for any fluctuations in the ground or machine movement. - High Frequency Vibration

To ensure the concrete is dense and free of air pockets, these machines are equipped with high frequency vibrators. This process not only levels the surface but also consolidates the material, leading to a stronger and more durable finished slab. - Automatic Leveling Head

The screed head is a multi-functional component that includes a plow to move excess concrete, an auger to distribute it evenly, and a vibratory finish beam. The synchronization of these parts allows for a smooth, professional finish in significantly less time than manual methods.

Applications in the Construction Industry

- Industrial Warehousing

In the age of automated logistics, warehouse floors must be exceptionally flat to allow high-reach forklifts to operate safely. Laser-level floors meet the stringent Super Flat Floor specifications required for high bay racking systems. - Commercial Parking Structures

Parking garages require specific slopes to ensure proper water drainage. Laser leveling machines can be programmed to handle complex multi-directional slopes, ensuring that water flows toward drains rather than pooling in the center of the driving lanes. - Airport Runways And Hangars

Aerospace environments demand the highest levels of structural integrity and surface smoothness. The consolidation provided by the vibratory systems in these machines ensures that runways can withstand the immense weight and friction of landing aircraft. - Sports Arenas And Exhibition Centers

Large public spaces require aesthetic perfection and structural reliability. Whether it is a foundation for an ice rink or a massive convention hall floor, laser technology provides the consistent finish necessary for high-traffic areas.

Structure of the Laser Concrete Leveling Machine

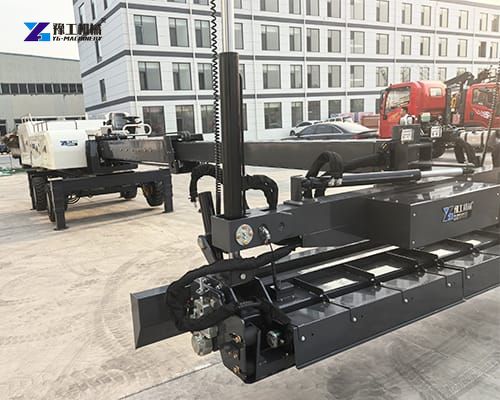

- The Chassis and Drive Train

The frame is typically built from high-strength steel to withstand the harsh environment of a construction site. Most machines utilize a Four Wheel Drive system with specialized tires that provide traction on wet concrete without sinking too deep into the subgrade. - The Telescopic Boom

On larger models, a telescopic boom allows the screed head to reach out over the wet concrete, meaning the heavy machine does not have to drive directly onto the freshly poured material as often. This minimizes disturbance to the reinforcement mesh or rebar. - Laser Receivers

Usually mounted on masts attached to the screed head, these sensors pick up the signal from the transmitter. They send real-time data to the onboard computer, which adjusts the hydraulic cylinders to raise or lower the screed head hundreds of times per minute. - Hydraulic Power Unit

The hydraulics provide the muscle for the machine. From moving the boom to powering the vibrators and the drive wheels, a robust hydraulic system is crucial for smooth operation.

Buying Guide: Selecting the Suitable Machine

Choosing the right laser concrete leveling machine depends on the specific needs of your business.

- Assess Project Scale

If you primarily work on residential driveways or small retail shops, a compact walk-behind model is more cost-effective and easier to transport. For large industrial contracts, a ride-on or boom extension model is a necessity. - Technical Support and Brand Reputation

These are high-tech machines that require maintenance. Choose a manufacturer with a strong reputation for reliability and the ability to provide parts and technical support when needed. - Ease of Operation

Look for machines with user-friendly interfaces. A machine that is easy to calibrate and operate will reduce the learning curve for your team and ensure better results from day one.