Hydraulic drum cutter is an advanced attachment designed to be mounted on a hydraulic carrier machine, typically an excavator, skid steer, or backhoe loader. Its core function is to efficiently cut and mill through various hard materials, including rock, concrete, asphalt, and frozen ground. The machine consists of two primary rotating drums, mounted either transversely (perpendicular to the excavator arm) or axially (lengthways) to the main body. These drums are equipped with numerous cutting tools, often referred to as picks or teeth, which are strategically positioned on the drum’s outer diameter. These picks are typically made of high-grade, wear-resistant materials like tungsten carbide to withstand extreme cutting forces and abrasion.

Hydraulic Drum Cutter Parameters

| Product Model | HX-X1 | HX-X2 | HX-Z1 | HX-Z2 | HX-D |

| Applicable Models | 6-9T | 10-18T | 20-27T | 30-40T | 45-60T |

| Machine Weight | 450kg | 550kg | 1100kg | 1250kg | 2450kg |

| Milling Width | 420mm | 650mm | 850mm | 950mm | 1150mm |

| Milling Head Diameter | 340mm | 450mm | 560mm | 660mm | 850mm |

| Number of Blade Heads | 40 | 56 | 64 | 64 | 60 |

| Recommended Speed | 95r/min | 85r/min | 78r/min | 75r/min | 55r/min |

| Recommended Flow Rate | 80L/min | 120L/min | 220L/min | 320L/min | 360L/min |

| Maximum Pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Maximum Torque | 4700NM | 7000NM | 14300NM | 23300NM | 40300NM |

Features of a Hydraulic Drum Cutter

- High Precision Cutting: The cutter provides exceptional control, enabling accurate profiling, trenching, and surface leveling.

- Low Vibration and Noise: Reduces the risk of structural damage and enhances operator comfort, making it suitable for urban or indoor applications.

- High Torque Performance: The hydraulic system ensures strong torque output for effective cutting through hard rock and concrete.

- Replaceable Picks: Carbide-tipped picks are easy to replace, reducing downtime and maintenance costs.

- Adaptability: Compatible with excavators, backhoes, and skid steer loaders of various sizes.

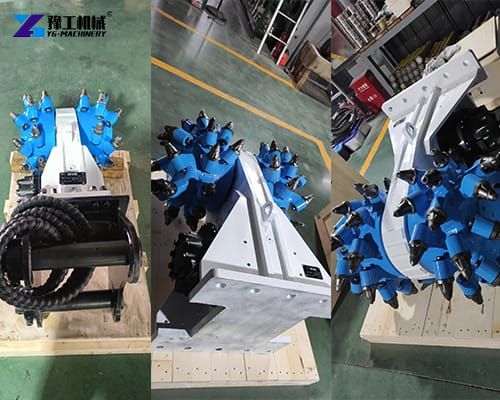

Components of Excavator Drum Cutter

The design of a hydraulic drum cutter emphasizes durability, stability, and precision. Its main components typically include:

- Hydraulic Motor: The powerhouse of the attachment, responsible for converting hydraulic pressure from the carrier into rotational motion.

- Twin Drums: Fitted with tungsten carbide-tipped picks, these drums rotate in opposite directions to evenly cut through material.

- Cutting Picks: Replaceable teeth made from hard alloy materials, capable of handling abrasive and high-strength rocks.

- Gearbox: Transfers torque efficiently from the hydraulic motor to the rotating drums.

- Mounting Bracket: Connects the cutter securely to the excavator’s arm and allows for flexibility in positioning.

Working Principle

The hydraulic drum cutter operates through a combination of hydraulic pressure and rotational motion. When the excavator supplies hydraulic oil to the cutter’s motor, it generates torque that rotates the twin drums. As the drums rotate, the picks engage with the rock or concrete surface, chipping away material bit by bit. This grinding process results in a controlled and uniform cut. The fragmented material is small and manageable, making it ideal for backfilling or removal. Because the excavator drum cutter cuts rather than impacts, it minimizes vibration and noise levels while preserving the stability of surrounding structures.