A laser concrete leveling machine has been exported to New Zealand. The New Zealand client, a contractor specializing in commercial floor construction, was seeking advanced equipment to improve concrete surface flatness and speed up large-area pouring projects. Their main requirement was a reliable, high-precision laser concrete leveling machine suitable for both indoor and outdoor projects. The equipment ensure a perfectly flat and even surface, eliminating the need for traditional methods such as manual leveling or the use of cumbersome machinery. This not only saves time and labor costs but also ensures a higher quality finish for construction projects.

Laser Concrete Leveling Machine Specifications

| Model | YG-CL300 |

| Engine model | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) |

| Engine type | Gasoline, air-cooled 4-stroke, twin-cylinder engine |

| Engine power | 22KW/30ps |

| Fuel capacity | 20L (operation time is about 8 hours |

| Hydraulic oil capacity | 37L |

| Laser transmitter | Swiss Leica/Tower transmitter (optional) |

| Laser receiver | Swiss Leica/Tower receiver (optional) |

| Laser system control effect | Plane, slope, double slope (three-dimensional) |

| Laser system control method | Microcomputer laser scanning |

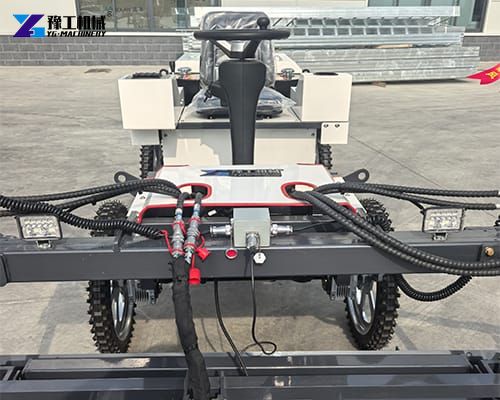

| Paving method | Hydraulic stirring cage paving |

| Vibration method/excitation force | Hydraulic vibration/2000N |

| Vibration plate width | 2500mm |

| Leveling thickness | 50-300mm |

| Travel drive | Reducer motor integrated |

| Travel speed | 0-4Km/h (speed adjustable) |

| Travel tire | Solid anti-skid and anti-puncture tires (optional wide tires) |

| Body size | 3250x2850x1320mm |

Why Choose YG Concrete Laser Leveling Machine?

- Advanced Laser System: Ensures accurate leveling with real-time feedback.

- High Working Efficiency: Covers large floor areas quickly and evenly.

- User-Friendly Controls: Simplified operation reduces labor intensity.

- Sturdy Build: Engineered for demanding job site conditions.

Benefits of Laser Concrete Leveling Machine Exported to New Zealand

Unmatched Precision: Our machines leverage advanced laser guidance systems to achieve exceptionally flat and level concrete surfaces, exceeding industry standards for quality and finish.

Increased Productivity: By automating the leveling process, laser concrete leveling machine significantly reduce labor requirements and project timelines. People can pour and finish concrete faster, leading to higher output, reduced overheads, and the ability to take on more projects.

Enhanced Efficiency & Cost Savings: The speed and accuracy of our laser screeds minimize material waste and rework, resulting in substantial cost savings.