The vibratory pile driver is a special pile-driving tool for excavators. It is a piling machine that uses impact force to penetrate the column into the ground. Excavator vibro hammer can replace different jaws according to different types of piles for piling construction. The excavator pile driver adopts imported bearings and seals, which can work underwater. It has good impact force, large filling thickness, and strong vibration force. It has a wide application in short and medium-pile projects such as municipal projects, bridges, and building foundations. In addition, YG also provides various excavator attachments. If you are interested in them, welcome to get in touch with us to get more detailed information and free quotation. Whatsapp/Wechat/Phone: +86 183 3712 3872 Email: admin@yugongengineering.com

Vibratory Pile Driver Models

| Model | YG-45 | YG-80 | YG-125 |

| Applicable models | 12-18T | 20-27T | 30-40T |

| Recommended traffic | 113L | 200L | 260L |

| Work pressure | 35Mpa | 35Mpa | 35Mpa |

| Maximum excitation force | 343KN | 450KN | 695KN |

| Shock frequency | 2500rpm | 2500rpm | 2080rpm |

| Maximum Pullout Force | 120KN | 120KN | 168KN |

| Piles can be driven outside the diameter | ≤300mm | ≤300mm | ≤300mm |

| Total Weight | 1350KG | 2300KG | 2800KG |

| Machine size | 2306*1268*680mm | 2306*1268*680mm | 2610*1616*746mm |

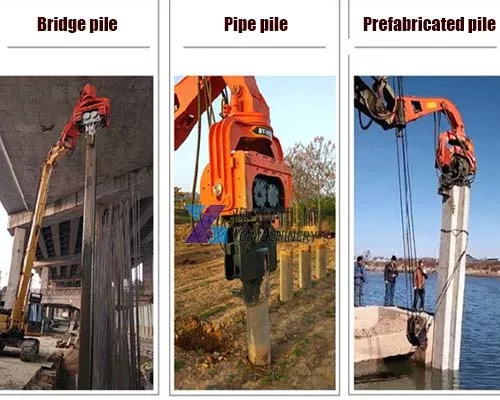

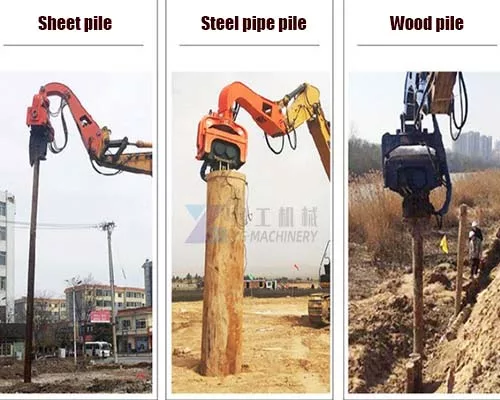

Applicable Scene

YG excavator and attachment manufacturer offers many different pile driver grips. By changing different clips, it can be widely used in various engineering constructions. Excavator vibro hammer can meet the construction needs of various steel sheet piles, I-beams, U-shaped piles, cement piles, and wooden piles. In addition, YG supports customized services and can customize non-standard pile driver chucks according to the user’s construction needs. If you want to know more details about vibratory pile drivers, please contact us.

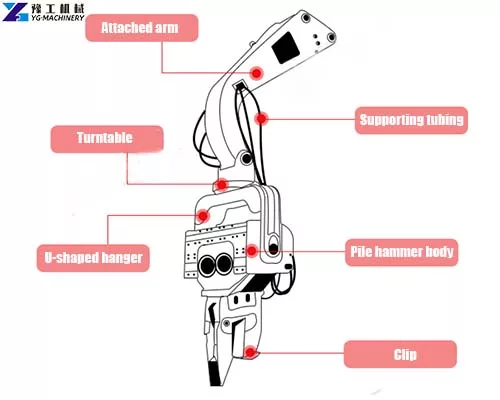

Excavator Vibro Hammer Structure Display

As shown in the figure, the excavator vibro hammer mainly consists of the attached arm, the supporting oil pipe, the turntable, the U-shaped hanger, the main body of the pile hammer, the clamping nozzle, and other structures.

The length of the piling arm can be lengthened according to the distance of the piling.

YG matches a variety of different chucks, and you can choose to match different piling chucks according to your construction conditions.

How Does The Excavator Pile Driver Work?

The excavator pile driver is designed by using the principle of resonance. It generates up and down vibration through the relative movement of two eccentric gears, which separates the object from the surrounding soil layer, reduces frictional resistance, and achieves the purpose of sinking and pulling. Connected to the excavator, the excavator provides oil flow for the hydraulic hammer. The force of the excavator boom can increase the penetration rate of the sheet piles. Vibration blowing can be widely used in different soils.

Advantages Of Vibratory Pile Driver

- High piling efficiency. The construction speed of a vibratory pile driver is faster than other piling machines, and the efficiency is 40%~100% higher than pneumatic hammers and diesel hammers.

- Wide range of applications. A high-frequency hydraulic excavator pile driver is suitable for almost all geological conditions (except rock entry). It can easily penetrate pebble layers, sand layers, and other geology.

- Versatile. Hydraulic excavator vibro hammers not only work in the construction of various bearing piles but also work in the construction of thin-walled anti-seepage walls, deep compaction treatment, ground compaction treatment, and other constructions.

- Low energy consumption. Small shocks and low noise when working. In addition, it can match with a noise-reduction power box. And it can meet the requirements of low consumption during construction in urban areas.

Excavator Vibro Hammer Features

- Adopt imported hydraulic vibration motor, double the efficiency and guarantee.

- YG provides various styles of clamps, and users can choose the appropriate clamps according to their construction conditions.

- Excavator vibro hammer jaws use high-strength steel plates to meet the requirements of high-frequency vibration, and the jaws adopt wear-resistant materials.

- The vibratory pile driver has a wide range of applications, including steel sheet piles, cement piles, rail piles, iron plates, H steel, steel pipes, etc.

- Quick job changeover between piling and pile extraction.

- Will not damage the top or bottom of steel pipe piles, steel sheet piles, and rail piles.

- There will be no noise during operation, quiet operation, and short construction period.

- The hydraulic cylinder has the design of a safety valve structure to ensure that the clamping force will not reduce when the equipment the suddenly pressed during the construction process, protecting people and equipment safety.

Vibro Hammer VS Impact Pile Hammer

Hydraulic pile hammers are divided into two types: Impact pile hammers and excavator vibro hammers.

The vibratory pile driver uses hydraulic oil to push the shaft force block to rotate at high speed, thereby causing high-frequency vibration. Through the rapid commutation of the high-pressure oil passage, the inside of the hammer body completes high-frequency high-voltage, and low-voltage transitions, thereby causing the hammer body to vibrate. It is suitable for sinking and pulling out of all kinds of just-installed concrete pouring piles. The excavator vibro hammer does not make a lot of noise when it works. It is lightweight and can be used underwater.

Impact pile hammer impacts the anvil with the hammer core of the internal structure, and transmits the impact force to the soil pile to complete the soil pile penetration work. The hydraulic piling hammer has low energy consumption, less environmental pollution, high efficiency, and good engineering construction adaptability.

Vrious Excavator Attachments Available in YG Machinery

We not only provide the vibratory pile drivers, but also supply concrete pile breakers, scrap metal shear for excavators, hydraulic breaker hammers, hydraulic plate compactors, log grapple, car dismantling shear, excavator pile drivers, hydraulic magnet for excavator, hydraulic pulverizer, milling head for excavator, vehicle dismantler, hydraulic quick hitch, excavator rock saw, and other excavator attachments.