Paper roll slitting rewinding machine is the special equipment to slit a jumbo roll of material into small rolls. It’s widely used in the paper product industry, packaging industry, and other industries that need rolls of materials. The main process mainly includes unwinding, cutting, rolling, and rewinding. The finished products with small rolls have wide applications, and easy to use, transport, and store. There are various specifications for the paper slitter rewinders available. People can choose the paper slitter rewinder machine according to their actual needs. If you are looking for this machine, please get in touch with us to learn more detailed information and free quotation. Email:admin@yugongengineering.com, Whatsapp/Wechat/Phone: +86 183 3712 3872

Parameter of the Paper Slitting and Rewinding Machine

| Model | YG-1100A | YG-1300A | YG-1600A | YG-1800A |

| Max. Unwinding width | 1100mm | 1300mm | 1600mm | 1800mm |

| Max. Unwinding diameter | 1400mm | 1400mm | 1400mm | 1400mm |

| Max. Rewinder diameter | 1000mm | 1000mm | 1000mm | 1000mm |

| Min. Rewinder web width | 50mm | 30mm | 30mm | 30mm |

| Slitting speed | 10-350 m/min | 30-500m/min | 30-500m/min | 30-500m/min |

| Precision of slitting | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

| Slitting thickness | 20-200g (paper) | 15-500g/m² | 15-500g/m² | 15-500g/m² |

| Total power | 25kw | 26kw | 26kw | 38kw |

| Machine weight | 5600kg | 4500kg | 5200kg | 6000kg |

| Overall dimension | 4200*3200*1950mm | 4500*2800*1950mm | 4500*3200*1950mm | 4500*3800*1950mm |

Main Characteristics for Paper Roll Slitting Rewinding Machine

- High efficiency: High production capacity, capable of fast slitting operations, improving production efficiency.

- High precision: Adopt precise control systems and sensors that can accurately control the cutting size and position to ensure cutting accuracy.

- Wide application: The paper roll slitting rewinding machine can be adjusted according to different needs, and is suitable for different types of materials and products, with a high range of applications.

- Automation: Adopting an automatic control system, the slitting process is fully automatic, improving production efficiency.

- Easy operation: The paper slitting and rewinding machine usually has the characteristics of centralized panel operation and integrated circuit control, making the operation easy and fast.

Parts of the Paper Roll Slitting Machine

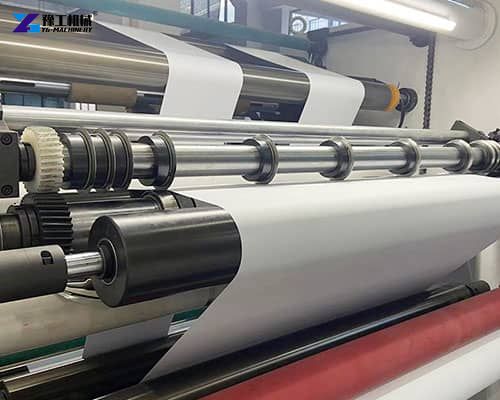

The paper roll slitting rewinding machine is composed of the cutter, rollers, transmission system, control system, etc. The cutting system is adjustable for the cutting width of the cutting material. The shafts are used to support large and small rolls. Its transmission system can ensure the smooth movement of the material during the cutting process. The control system is used to set cutting parameters and operate the machine.

What Materials Can the Slitting Machine Be Used for?

Applicable material: paper, offset paper, self-adhesive paper, coated paper, white cardboard, aluminum foil, PVC, BOPP, OPP, PET, plastic film, kraft paper, thermal paper, non-woven fabric, PP, PET, mica tape, film, transparent tape, and so on.

Applicable paper: 16gsm-500gsm

Things to Note When Purchasing

- Material type: Make sure the paper roll slitting and rewinding machine is suitable for processing specific materials based on your needs.

- Cutting accuracy: Choose the appropriate cutting accuracy according to requirements.

- Production efficiency: Consider the processing speed and capacity of the paper slitter rewinder machine.

- After-sales service: Choose a reliable manufacturer that provides good technical support and after-sales service.