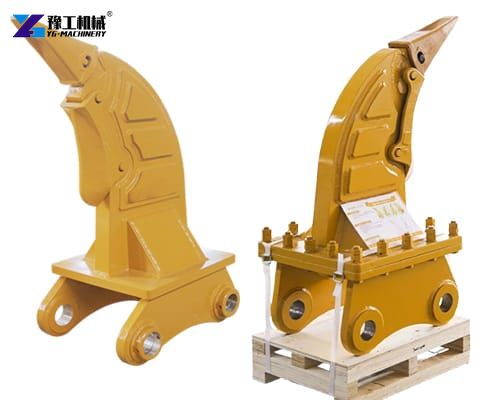

Excavator ripper for sale is used for loosening operations in hard soil layers, frozen soil layers, soft rocks, weathered rocks, and other geological conditions. It is made of manganese plate steel, which is high-strength and corrosion-resistant. The pin is made of alloy steel with built-in oil channels, high strength, and good toughness. The excavator ripper attachment is used to dig through cracked rocks, break up frozen soil, and penetrate asphalt surfaces. Suitable for crushing and splitting hard soil, semi-hard rock, and weathered rocks to facilitate digging and loading operations with a bucket.

Parameter of Excavator Ripper for Sale

| Model | YGR02 | YGR04 | YGR06 | YGR08 | YGR10 | YGR14 |

| suitable excavator | 4-6T | 5-9T | 9-16T | 16-23T | 23-30T | 30-39T |

| pin to pin distance | 265mm | 310mm | 390mm | 465mm | 520mm | 570mm |

| overall width | 375mm | 420mm | 570mm | 665mm | 740mm | 820mm |

| overall height | 390mm | 950mm | 1180mm | 1260mm | 1380mm | 1470mm |

| pin diameter | 40-50mm | 50-55mm | 60-70mm | 70-80mm | 80-90mm | 80-90mm |

| dipper width | 150-180mm | 180-200mm | 200-315mm | 300-350mm | 360-420mm | 360-420mm |

| plate thickness | 50mm | 55mm | 65mm | 80mm | 90mm | 90mm |

| teeth model | DH55type | DH150type | DH220type | D85Ctype | 4T5502-2type | 4T5502-2type |

| weight | 60kg | 160kg | 245kg | 420kg | 620kg | 775kg |

Features of An Excavator Ripper

- High-strength steel construction: Built from wear-resistant and hardened steel to withstand extreme forces.

- Sharp tooth: Designed to pierce through compacted layers, ensuring effective ripping.

- Simple design with maximum impact: Fewer moving parts for enhanced durability and lower maintenance costs.

- Compatibility with various excavator models – Available in different sizes and configurations to fit mini, medium, and large excavators.

- Reinforced shank and side plates: Provide extra stability and strength during heavy-duty operations.

Main Uses of An Excavator Ripper

- Breaking frozen ground: Ideal for working in cold regions where soil is solid and difficult to excavate.

- Loosening compacted soil: Prepares hard-packed surfaces for easier digging and removal.

- Ripping rocks and shale: Effective in quarrying and mining applications where blasting may not be possible.

- Demolition projects: Helps in tearing down reinforced concrete and other tough materials.

- Forestry and land clearing: Useful for removing tree roots, stumps, and rocky terrain before construction.

Advantages of Choosing An Excavator Ripper For Sale

- Enhanced productivity: Saves time by loosening materials faster than standard buckets.

- Cost efficiency: Reduces the need for additional machines or blasting in rocky conditions.

- Extended excavator life: Minimizes wear on the bucket and boom by handling the toughest tasks separately.

- Versatility: Can be used in multiple industries, from construction to agriculture and mining.

- Durability: With its robust structure, a ripper can last for years with proper maintenance.

How To Choose The Right Excavator Ripper For Sale?

- Match with excavator size: Ensure the ripper is designed for the tonnage of your excavator.

- Consider the soil or rock condition: For harder rock, a reinforced heavy-duty ripper is essential.

- Check tooth material and design: High-quality replaceable teeth extend service life.

- Look at compatibility: Verify the mounting bracket matches your excavator’s quick coupler or pin dimensions.