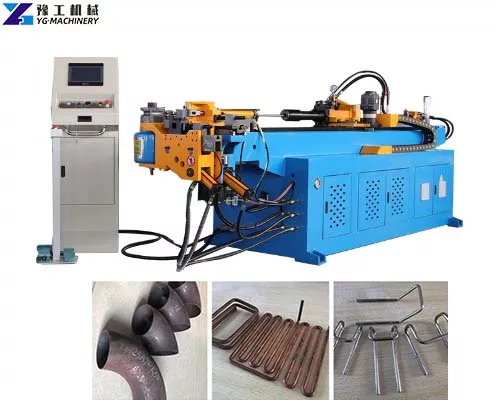

The CNC tube bending machine is a special pipe & tube bending equipment, which is three-dimensional forming equipment for various pipes, profiles, and bars. CNC pipe bender can process metal pipes into various angles, radii, radians, and shapes. It meets the needs of different industries for bending pipes. CNC pipe & tube bending machine has a very wide range of applications in road construction, ships, furniture, decoration, locomotives, and other industries. YG also provides stirrup bending machines, rebar straightening and cutting machines, punching and shearing machines, I-beam cold bending machines, and other steel bar processing equipment.

CNC Tube Bending Machine For Sale

| Function | Parameters |

| Maximum Bending Capacity Iron(S=40kgf/mm2 ) | 51 x3.0mm |

| The maximum elbow outer diameter when reciprocating feeding | 48 mm |

| Copper tube, aluminum tube( S=25kgf/mm2 ) | 51 |

| Round tube/stainless steel( S=60kgf/mm2 ) | 43 x3.0mm |

| Square iron pipe( S=40kgf/mm2 ) | 48 x2.5mm |

| Iron rod ( S=40kgf/mm2 ) | 40mm |

| Bending radius range | 35~200mm |

| Bending Radius Range/Square Tube | 35~200mm |

| Bending Angle Range | 190内 |

| The maximum effective distance through the heart | 2100mm |

| Maximum feeding length | 2700mm |

| Bending (D.O.B.) Speed | 35 deg/sec |

| Feeding (D.B.B.) Speed | 180 deg/sec |

| Rotating tube (P.O.B.) speed | 120deg/sec |

| Hydraulic system motor | 5.5kw |

| Total power | 7.25kw |

| Greatest pressure | 120 kg/cm2 |

| Preset pressure | 90 kg/cm2 |

| Fuel tank capacity | 120L |

| Equipment length x width x height | 3500 X1000X880 |

| Equipment weight | 1350kg |

Note: YG offers many kinds of CNC pipe benders for sale. Since the equipment bends steel pipes into different angles through different molds, YG also supports the customized production service of molds. If you want to know more about the pipe bender, please contact us.

What Is Tube Bending?

One of the most commonly used manufacturing methods is pipe bending, where the straight pipe is permanently formed into the pipe by bending. The arc bend itself has a small stress concentration, high strength, and good impact resistance. Therefore, bent pipes are more versatile than straight pipes. There are many uses of pipe bending processing, involving many fields. For example, bending processing equipment for pipe fittings such as auto parts, stair railings, furniture frames, air-conditioning equipment, ships, fitness equipment, sporting goods, etc.

Application Fields Of CNC Tube Bending Machine

Bends are used in many industries, and the following are the common uses of tube bends:

- Pipeline, ship pipeline, automobile oil pipe, etc.

- Furniture pipes. Office chairs, beach chairs, shopping carts, computer desks, etc.

- Bathroom elbows, faucets, towel racks, and S-shaped attachments.

- Air-conditioning refrigeration pipes, small U-shaped pipes, return-shaped pipes, etc.

- Sports equipment, fitness equipment, lighting, construction machinery, etc.

CNC Pipe Bender Operation Process

The use of CNC pipe bender roughly goes through the processes of material preparation, feeding, bending, returning, cutting, and collecting.

- Material preparation: Cut the pipe to be bent into a suitable length and place it in the feeder.

- Automatic feeding: The automatic feeding system of the CNC pipe bender feeds the pipe from the feeder into the bending area of the pipe bender.

- Bending: Through the machine’s motor and hydraulic system, the pipe bender automatically bends the pipe to a preset angle and shape.

- Automatic material return: After the bending is completed, the pipe bender will automatically return the bent pipe to the feeder.

- Automatic cutting: According to production needs, the pipe bender can be equipped with an automatic cutting system to cut the bent pipe.

- Automatic collection: CNC pipe bender can also be equipped with an automatic collection system to automatically collect the cut pipes for subsequent processing.

Function Of CNC Pipe & Tube Bending Machine

- Rapid production of customized metal pipes. Traditional metal pipe processing mostly adopts manual bending, which is not only time-consuming and labor-intensive but also prone to errors. The emergence of CNC pipe bending machines ensures that metal pipes can be processed quickly and with higher precision and quality.

- Improve production efficiency and reduce costs. The entire process of pipe bending is automated without manual intervention, improving production efficiency.

- Expand the scope of product application. CNC pipe & tube bender can bend and process metal pipes according to different needs, so it can produce metal pipes of various shapes to meet diverse needs.

- Improve product quality. When processing metal pipes, certain precision and quality can be guaranteed, thus improving the quality of products.

Features Of CNC Tube Bending Machine

- The performance of the equipment is stable. A pure copper wire generator is adopted, with high power and stable operation.

- Wide range of applications. The equipment is suitable for processing all kinds of pipe fittings.

- A variety of models to choose from to meet the needs of different industries. YG can also customize CNC tube bender machines according to the different needs of customers.

- Easy to use. Microcomputer control, multiple programs, and multiple angle settings make the operation and program setting more convenient.

- Hydraulic drive. It is suitable for bending pipes at multiple angles in three-dimensional space, with precise bending and forming, hydraulic drive, and powerful.

- The use of servo motors can effectively extend the service life of the machine.

- The hydraulic system of the machine is equipped with an automatic oil cooler device, which is convenient for the user to control the oil temperature.