Clay brick making machine is a brick made from clay, shale, coal gangue, etc. using a brick making machine. Clay bricks are small man-made bricks used in construction. Clay bricks are widely used in civil engineering due to the convenience of obtaining materials, low price, and durability. By changing different forming molds, the clay brick making machine can make hollow bricks and solid bricks. YG also offers other block brick making machines, such as concrete brick making machines, small clay brick machines, automatic clay brick makers, hollow block making machines, etc.

Applications of Clay Bricks

Clay bricks have wide applications in the metallurgical industry, chemical industry, ceramic industry, building materials industry, etc. In the metallurgical industry, clay bricks are used as raw materials for the production of shaped refractories and unshaped refractories, accounting for 70% of all refractories. High-alumina clay is melted in an electric arc furnace to produce abrasive materials. Fused corundum abrasive is currently the most widely used abrasive. In addition, high alumina clay can also produce various aluminum compounds, such as aluminum sulfate, aluminum hydroxide, potassium aluminum sulfate, and other chemical products. Finally, clay bricks are widely used in the building materials industry. High alumina clay is calcined and mixed with limestone to make aluminum cement, which has the characteristics of rapid setting ability, strong corrosion resistance, and heat resistance.

4 Process to Make Brick From Clay

- Mix the raw materials. Select fine pure soil, use water to moisten it and make thick mud after repeating and practicing.

- Clay molding. Put the mixed thick mud into the molding die of the clay brick making machine and press it into shape. The shape of the mold determines the shape of the clay molding. So, if you want to make a special shape clay brick, please send it to us for customization.

- Demoulding and drying in the shade. After de-molding, place the formed clay bricks in the shade to dry in the shade to prevent cracks and deformation from exposure to the sun.

- Firing. Unlike concrete bricks made by concrete brick making machines, red clay bricks need to be fired. When firing red clay bricks, it needs to be baked in an oven below 1800 degrees Fahrenheit.

Advantages of Clay Bricks

- The material is easy to obtain and the cost is low. The raw materials for making clay bricks are readily available and inexpensive.

- Good fire and heat insulation. The produced clay bricks are not only durable, but also have the advantages of fire prevention, heat insulation, sound insulation, moisture absorption, etc., and are widely used in civil construction projects.

- Good stability. Clay bricks are weakly acidic at high temperatures, and their resistance to alkaline slag erosion is slightly worse, but with the increase of Al2O3 content, the thermal stability is better than that of silica bricks and magnesia bricks.

- It can be used to build the upper lining of the blast furnace body. Qualified blast furnace clay bricks are dried, vacuum phosphoric acid-impregnated products and phosphoric acid-impregnated products are fired at a secondary low temperature, which can be used to build the upper lining of the blast furnace body.

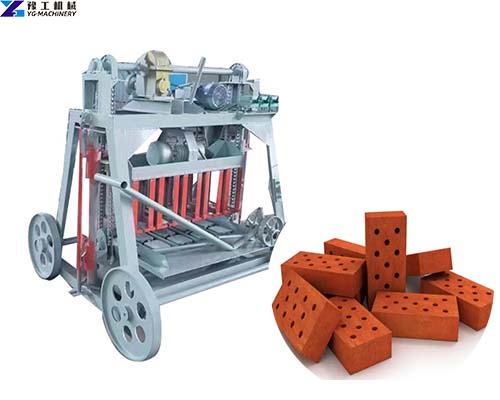

Features of Clay Brick Making Machine

- Less input and high output. Compared with the same type of brick making machine manufacturers in the market, YG’s clay brick making machine has good quality, low capital investment, and high output.

- The production method is flexible and easy to implement. YG’s clay brick machine is small and consumes less energy. It can be moved to any place that needs to be open for operation.

- Simple operation, easy to learn, easy to understand, easy to maintain, and easy to use.

- There are many varieties and all kinds. YG brick-making machine manufacturers have small, semi-automatic, and fully automatic equipment to meet the production needs of large and medium-sized enterprises.

- Adopt hydraulic transmission power, no noise, high output, and high density.

- The molding shape is good. The clay bricks formed by the molding die of the clay brick-making machine have clear edges and corners, and the pressed porcelain is solid.

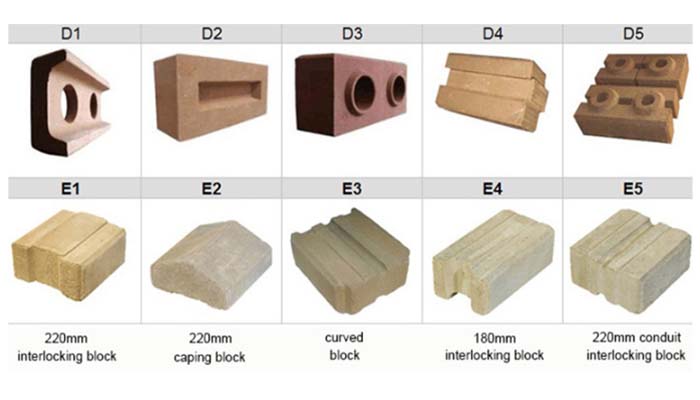

- There are many molding styles. YG block brick making machine manufacturer offers a wide range of brick-forming molds. Moreover, YG also supports customized service of molds. Therefore, if you need to make a variety of bricks or form complex shapes, please contact us for custom molds.

- Solid clay bricks and hollow clay bricks can be produced to meet the needs of different customers.

Clay Brick Making Machine Classification

Depending on the degree of automation, clay brick making machines include small clay brick makers and fully automatic clay brick machines.

Small Clay Brick Making Machine

A small clay brick making machine is usually a clay brick-forming host. You need to mix the ingredients first, then use labor to spread the ingredients on the mold. Then only need to operate the machine for pressing. The formed clay bricks can also be unloaded by machine operation without the need for labor to move them down. There are also various models of small manual brick making machines, which can produce 2~12 bricks at a time.

Automatic Clay Brick Making Machine

The automatic clay brick making machine has a relatively high degree of automation. It can realize fully automatic from raw material transportation to forming, molding, and blanking. A fully automatic clay brick machine is usually connected with a raw material mixer and a conveyor belt, stacker, and other equipment to achieve fully automatic work. The raw materials mixed by the mixer directly enter the automatic brick-making machine through the conveyor belt to be formed. The formed bricks are stacked by a stacker.