Automatic concrete leveling machine is a construction device designed to distribute, level, and finish freshly poured concrete with minimal human intervention. Using sensors, control systems, and mechanical components, the machine automatically adjusts its height and movement to achieve a smooth and even concrete surface. Compared to manual screeding or semi-automatic tools, this machine relies on intelligent control technology to maintain consistent thickness and flatness. The result is higher accuracy, reduced labor dependency, and improved construction efficiency.

Automatic Concrete Leveling Machine Specifications

| Model | YG-CL300 | YG-CL300A | YG-ZP30 |

| Engine model | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) | Yanmar 4TNV94L |

| Engine type | Gasoline, air-cooled 4-stroke, twin-cylinder engine | Gasoline, air-cooled 4-stroke, twin-cylinder engine | Diesel |

| Engine power | 22KW/30ps | 22.8KW/23ps/31ps | 35.5KW/48hp |

| Fuel capacity | 20L (operation time is about 8 hours | 20L (operation time is about 8 hours | 100L |

| Hydraulic oil capacity | 37L | 35L | 150L |

| Laser transmitter | Swiss Leica/Tower transmitter (optional) | Swiss Leica/Tower transmitter (optional) | Danfoss |

| Laser receiver | Swiss Leica/Tower receiver (optional) | Swiss Leica/Tower receiver (optional) | American Tempo |

| Laser system control effect | Plane, slope, double slope (three-dimensional) | Plane, slope, double slope (three-dimensional) | German Mopar |

| Laser system control method | Microcomputer laser scanning | Microcomputer laser scanning | Flat, inclined or double slope (3D) |

| Paving method | Hydraulic stirring cage paving | Hydraulic stirring cage paving | Microcomputer laser scanning |

| Vibration method/excitation force | Hydraulic vibration/2000N | Hydraulic vibration/2000N | Hydraulic Cage Paving |

| Vibration plate width | 2500mm | 3000mm | Hydraulic motor |

| Leveling thickness | 50-300mm | 60-300mm | Flip up and down for easy cleaning, left and right switching, blades made of highly wear-resistant material, more durable |

| Travel drive | Reducer motor integrated | Reducer motor integrated | 6000mm |

| Travel speed | 0-4Km/h (speed adjustable) | 0-4Km/h (speed adjustable) | 3100mm |

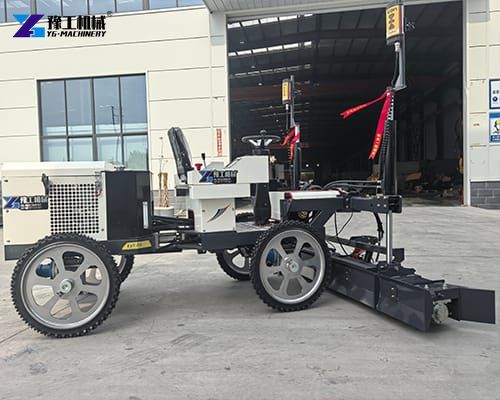

| Travel tire | Solid anti-skid and anti-puncture tires (optional wide tires) | Solid anti-skid and anti-puncture tires (optional wide tires) | 100-450mm |

| Body size | 3250x2850x1320mm | 3300x3460x1650mm | 4-8km/h 24m/min |

Features of the Concrete Laser Leveling Machine

- One of the defining features of an automatic concrete leveling machine is its precision control system. Advanced sensors detect surface height variations in real time and instantly adjust the leveling mechanism. This ensures uniform concrete surfaces even across large areas.

- Another important feature is automation. The machine can operate continuously with minimal operator input, reducing fatigue and human error.

- Durability is also a standout feature. These machines are built using high-strength steel frames, wear-resistant components, and robust motors designed to withstand harsh construction environments.

Structural Components of Concrete Laser Screed

- The Chassis: This is the heavy-duty frame that supports the engine, hydraulic tanks, and operator cabin. It is built to withstand the harsh conditions of a construction site.

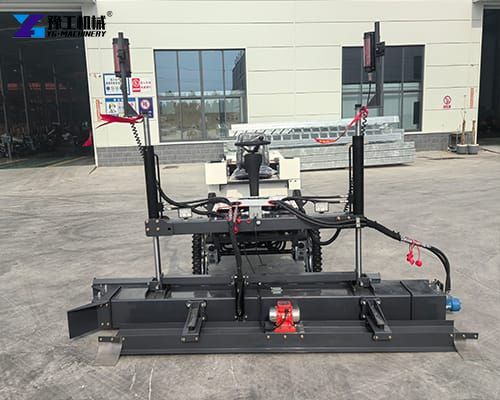

- The Screed Head: This is the business end of the automatic concrete leveling machine. It typically consists of a plow to move excess concrete, an auger to distribute it evenly, and a vibrator to densify the mix and bring the cream to the surface.

- The Laser Receivers: Mounted on masts at either end of the screed head, these sensors pick up the signal from the stationary laser transmitter.

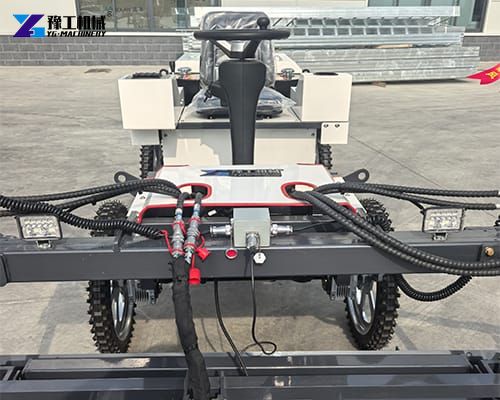

- The Hydraulic System: This system powers the movement of the boom and the constant adjustments of the screed head. It must be incredibly responsive to maintain the required accuracy.

- The Power Unit: Usually a high torque diesel or electric engine that provides the necessary power for both locomotion and the intensive vibration required for concrete consolidation.

Laser Concrete Leveling Machine Applications

The automatic concrete leveling machine is widely used across multiple construction sectors. In industrial settings, it is essential to produce flat warehouse floors that support heavy machinery and high traffic loads. In commercial buildings, it ensures smooth and visually appealing concrete surfaces for shopping centers, parking structures, and office complexes. In infrastructure projects, such as highways, bridges, and airport runways, the machine helps achieve strict flatness and slope requirements. Residential construction also benefits, especially for large floor slabs, basements, and garages, where consistency improves both functionality and aesthetics.

Advantages Over Traditional Methods

- Compared to manual leveling, the automatic concrete leveling machine offers significant advantages. The most obvious benefit is accuracy. Automated systems maintain a level of precision that is extremely difficult to achieve by hand, especially over long distances.

- Efficiency is another major advantage. Automated leveling dramatically reduces construction time, enabling faster project completion and lower labor costs. With fewer workers required on site, safety risks are also reduced.

- Consistency is equally important. Traditional methods often produce uneven surfaces due to operator fatigue or skill differences. Automated machines deliver uniform results every time, improving overall project quality and reducing the need for rework.

Working Principle

- The working principle of an automatic concrete leveling machine is based on real time feedback and mechanical adjustment. Once the machine is positioned over freshly poured concrete, sensors measure surface height relative to a reference level.

- These measurements are sent to the control unit, which calculates necessary adjustments. The leveling beam is then raised or lowered automatically to correct any deviations. Simultaneously, vibration ensures proper concrete compaction.

- As the machine moves forward, this process repeats continuously, resulting in a smooth, level surface without interruptions. This closed loop system is what enables high precision and reliability.

Essential Maintenance

Proper maintenance of an automatic concrete leveling machine is vital to ensure longevity and reliable performance.

- Routine maintenance includes daily checks, such as inspecting the frame for cracks, cleaning sensors and leveling components to prevent concrete buildup, and verifying fluid levels in engines or hydraulic systems.

- Weekly tasks might involve lubricating moving parts, testing electronic controls, and calibrating guidance systems to maintain accuracy.

- It is also important to follow guidelines for seasonal storage, especially in extreme climates, to avoid corrosion or damage.