Roll to roll slitting machine is a specialised piece of equipment designed to cut wide rolls of material into narrower rolls while maintaining consistent tension and alignment. The process, known as “slitting,” is a vital step in converting raw materials into usable forms for packaging, printing, labelling, electronics, and other industries. From flexible packaging films to adhesive tapes, a roll-to-roll slitting machine provides a perfect solution for high-volume material conversion

Roll to Roll Slitting Machine Parameter

| Model | YG-1300C | YG-1600C | YG-1800C |

| Max. Unwinding width | 1300mm | 1600mm | 1800mm |

| Max. Unwinding diameter | 800mm | 800mm | 800mm |

| Max. Rewinder diameter | 600mm | 600mm | 600mm |

| Finished width | 30-1300mm | 30-1600mm | 30-1800mm |

| Slitting speed | 30-500m/min | 30-500m/min | 30-500m/min |

| Precision of slitting | ±0.2mm | ±0.2mm | ±0.2mm |

| Slitting thickness | 10-300g/m² | 10-300g/m² | 10-300g/m² |

| Total power | 30kw | 30kw | 30kw |

| Machine weight | 3700kg | 4200kg | 4800kg |

| Overall dimension | 4200*2600*1650mm | 4200*2900*1650mm | 4200*3400*1650mm |

Features of Paper Roll Slitting Rewinding Machine

- Automatic tension and web guiding systems for superior accuracy.

- High-speed operation with adjustable settings for different materials.

- Touchscreen PLC control for easy monitoring and parameter adjustment.

- Razor, shear, or score slitting options to handle a wide range of materials.

- Automatic roll change and turret winding for continuous production.

- Compact design with low noise operation for improved workplace comfort.

- Precision blade positioning systems for fast and accurate slitting width adjustments.

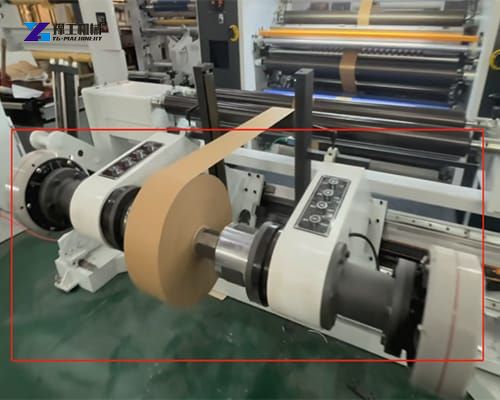

Components of Paper Slitter Rewinder

The structure of a roll-to-roll slitting machine is a combination of precision mechanical engineering and intelligent control systems. Each part works in harmony to deliver efficient, accurate, and high-speed cutting.

- Unwinding Unit

The unwinding unit holds the mother roll and ensures smooth feeding of material into the slitting section. Advanced models are equipped with automatic tension control and edge guiding systems to maintain material alignment. - Slitting Section

This is the heart of the machine. It includes razor blades, rotary knives, or shear slitting systems, depending on the material type and thickness. The blades are precisely adjustable to ensure clean and consistent cuts. - Rewinding Unit

After slitting, the machine rewinds the narrow strips onto separate cores. Dual or turret rewinding systems are used for efficient roll changeovers and continuous production. - Tension Control System

Maintaining proper tension is critical in roll-to-roll processing. Modern machines use load cells and servo motors to regulate web tension dynamically, preventing stretching or wrinkling. - Drive System

Multiple servo motors control each section independently, providing smooth acceleration, deceleration, and synchronisation for consistent roll quality.

Advantages of Using Paper Slitting Machine

- Enhanced productivity

High-speed slitting allows more material to be processed in less time. - Superior accuracy

Precision cutting reduces scrap waste and improves product consistency. - Improved roll quality

Proper rewinding tension results in rolls that are smooth, uniform and reliable for downstream processes. - Cost savings

Reduced manual labour, minimised material waste, and optimised efficiency to lower operational expenses. - Better customisation capability

With adjustable slitting width and configuration, manufacturers can easily cater to specific client requirements. - Stable production

Machines equipped with servo drives and digital control reduce downtime and maintain a steady workflow.

Choosing the Suitable Paper Roll Slitting Machine

- Consider material type and thickness

Different materials require different slitting methods, tension levels, and blade configurations. - Required slitting width and number of strips

Make sure the machine supports precise knife positioning and has enough knife holders. - Production speed

Higher-speed machines may cost more but significantly increase capacity. - Budget Vs. long-term value

Cheaper machines may cost more in maintenance and downtime. A reliable machine offers a higher return on investment.