Drum cutter for excavator is a specialized attachment engineered to grind, cut, or mill hard materials such as rock, concrete, asphalt, and frozen ground. The core components include a rotating drum embedded with tungsten carbide teeth or picks, driven by the excavator’s hydraulic system. This design allows for precise control, enabling operators to achieve clean cuts, uniform trench walls, or accurate surface profiling. The drum cutter for an excavator is a hydraulic attachment mounted on the arm of an excavator. It converts the excavator’s hydraulic energy into high torque and precision cutting power.

Drum Cutter for Excavator Parameters

| Product Model | ZX-1 | ZX-2 | ZX-3 | ZX-4 |

| Applicable Models | 6-9T | 10-18T | 20-27T | 30-40T |

| Machine Weight | 340kg | 480kg | 900kg | 1100kg |

| Milling Head Diameter | 400mm | 450mm | 550mm | 580mm |

| Number of Blade Heads | 28 | 32 | 44 | 48 |

| Recommended Speed | 80r/min | 80r/min | 75r/min | 65r/min |

| Recommended Flow Rate | 75L/min | 120L/min | 200L/min | 260L/min |

| Maximum Pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Maximum Torque | 3780NM | 7900NM | 12700NM | 19600NM |

Features of Excavator Drum Cutter

The drum cutter for excavator is built with efficiency, strength, and adaptability in mind. Below are some of their defining features:

- High-Torque Hydraulic Motors

Drum cutters are powered by high-torque hydraulic motors that provide the strength needed to cut through even the hardest materials. The hydraulic drive ensures consistent performance and smooth operation under demanding conditions. - Replaceable Tungsten Carbide Picks

Each drum is fitted with multiple tungsten carbide teeth, which offer exceptional hardness and durability. These picks can be easily replaced, ensuring long-term usability and reducing maintenance costs. - Adjustable Cutting Widths

Depending on the model, drum cutters offer adjustable cutting widths, enabling operators to adapt the tool for specific project requirements. - Low Noise and Vibration Levels

One of the major benefits of using a drum cutter for an excavator is its reduced noise and vibration compared to impact tools. This feature enhances operator comfort and minimizes structural damage in sensitive environments.

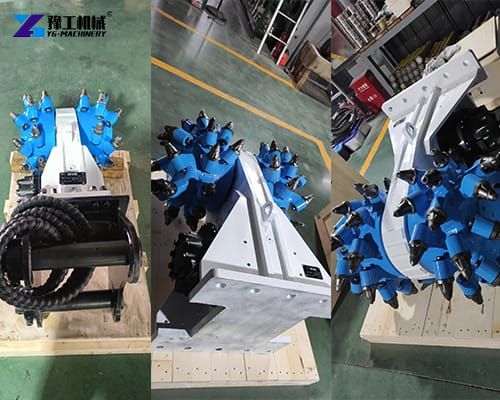

Structure and Working Principle Detailed

- Mounting Bracket: The heavy-duty component that connects the drum cutter for excavator securely to the excavator arm or quick coupler.

- Hydraulic Motor Assembly: The heart of the system, consisting of one or two powerful hydraulic motors (often high-torque, low-speed motors) that convert the excavator’s hydraulic flow and pressure into rotational energy.

- Gear Housing: A robust, sealed unit housing the spur gears. These gears transmit the high torque from the motor to the cutting drums, ensuring durability and power even in the most demanding conditions.

- Cutting Drum: The core working part, typically cylindrical, mounted on oversized bearings.

- Cutting Tools (Picks): Wear-resistant, carbide-tipped picks or teeth strategically placed on the drum surface. These are the tools that physically engage and fracture the material. They are often replaceable.

Applications and Industry Benefits

- Tunneling and Mining: Ideal for scaling concrete walls, excavating soft rock, or creating precise tunnel profiles.

- Demolition: Efficiently break down concrete structures, bridges, or foundations with minimal debris.

- Road Construction: Mill asphalt or concrete surfaces for repairs, ensuring level bases for new layers.

- Underwater Work: It can operate underwater without modification, useful for dredging or submerged infrastructure.

- Environmental Remediation: Remove contaminated soil or frozen ground in ecologically sensitive zones.

Advantages of Using A Drum Cutter for Excavator

- Precision And Control

Drum cutters allow for highly controlled material removal, ensuring accuracy and safety in confined spaces. - Lower Environmental Impact

With minimal dust, vibration, and noise, drum cutters are environmentally friendly and suitable for urban construction sites. - Reduced Wear On Excavator

The smooth cutting action reduces stress on the excavator’s boom and hydraulic system. - Versatility

One attachment can handle various materials and project types, from trenching to demolition, saving time and equipment costs.

How to Select The Right Drum Cutter for Excavator?

Choosing the correct drum cutter model is critical for achieving optimal performance and cost efficiency. Here are key factors to consider:

- Excavator Size And Hydraulic Flow

Ensure the drum cutter machine matches your excavator’s hydraulic specifications, including flow rate and pressure. A mismatch may cause power loss or mechanical strain. - Material Type And Hardness

Different materials require different pick types and drum configurations. Hard rock needs reinforced picks, while softer materials can be cut with standard picks. - Cutting Width And Depth

Select a drum cutter with suitable cutting dimensions for your specific trenching or profiling needs. - Weight Compatibility

The attachment’s weight should be proportionate to your excavator to maintain stability and prevent damage.