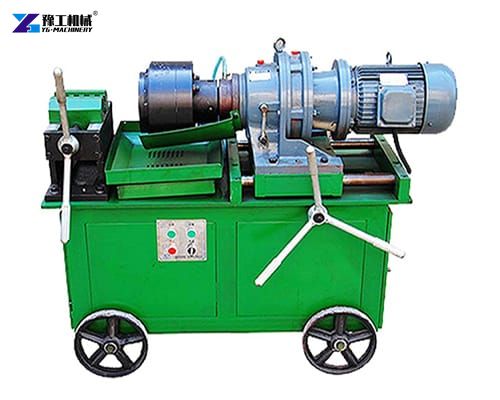

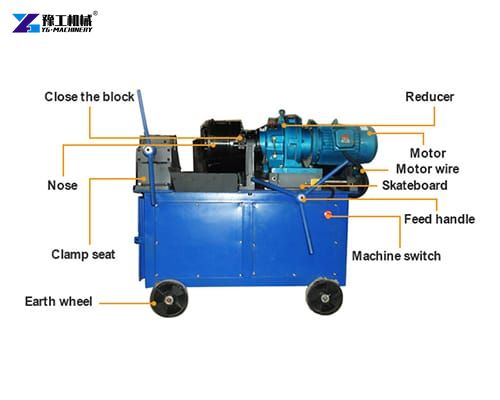

Rebar thread rolling machine is a steel bar processing machine widely used in the construction industry, casting, forging, machining, and other sectors in recent years. Its main function is to form threads on the end of metal materials by rolling, and is usually suitable for the production of fasteners such as screws, bolts, and others, with quick steel bar end part rolling. The working principle of the rebar threading machine usually involves clamping the metal pieces on the machine and using the thread rolling tool to process the metal at high speed to form the required thread shape. It consists of a frame, a clamping mechanism, a feed slide, a reducer and a thread rolling head, a cooling system, and an electrical system.

Rebar Threading Machine Parameter

| Model | YGS-40F |

| Diameter range of processed steel bar | φ16-φ40mm |

| Main motor power | 4.0kw |

| Power supply | Three-phase 380V 50Hz |

| Spindle speed | 72r/min |

| The maximum processing length | 80mm |

| Weight | 400kg |

Advantages of Rebar Thread Rolling Machine

- High efficiency: The rebar threading machine has a fast processing speed and is suitable for large-scale production.

- Smooth surface: After processing, the thread surface is smooth, reducing the subsequent processing steps.

- Improve strength: During the rolling process, the grain structure of the metal may be improved, so the formed thread strength is higher.

- Various types are available: People can select the appropriate models and specifications according to different production needs.

- Wide application: Suitable for 16~40mm diameter ribbed bars. It is the key equipment to realize the connection of rebars.

- High strength: After processing, the tensile strength is increased by 20%-30%, the fatigue strength is increased by 40%-60%, and the corrosion resistance is increased by 50%-200%.

Use of the Rebar Threading Machine

The steel bar rolling straight thread connection technology is suitable for industrial and civil buildings. It has a simple and fast process, no open flame operation, no environmental pollution, safe and reliable, and can be constructed for a long time, saving a lot of steel and energy. Each steel bar joint takes about one minute, which shortens the construction period of the structure. The stripping and rolling thread head processing can be completed in one clamping. The processing shape is full and the dimensional accuracy is high. With simple operation, compact structure, and reliable operation, the rebar thread rolling machine has a unique tool automatic opening and closing mechanism. The steel bar can complete the thread head processing in one clamping, with high efficiency.

Why Rebar Thread Rolling Machine Is Needed?

- The thread rolling machine for the steel bar is mainly used to process the thread of the steel bar head, making it easier to connect and fix it to other steel bars or components.

- Adopt advanced mechanical transmission and control technology, simple and convenient to operate, with high work efficiency and fast processing speed.

- With stable operation and high precision, it can ensure the quality of the processed threads is stable and reliable.

- Made of high-strength materials, it is wear-resistant and durable and is not easily damaged after long-term use.

- Reasonable design, compact structure, small footprint, suitable for operation in small spaces such as construction sites or factories.

- Strong versatility, can roll steel bars of different specifications and diameters, suitable for various construction projects and steel structure manufacturing fields.

Related Rebar Processing Machines

The customers who bought the rebar thread rolling machine usually also need a rebar upsetting machine for processing the end of the steel bars. Besides, we also have rebar bending machines, rebar straightening and cutting machines, reinforcement stirrup bending machines, etc. If you are looking for rebar processing equipment, please contact us and we will do our best to provide suitable machines for you.