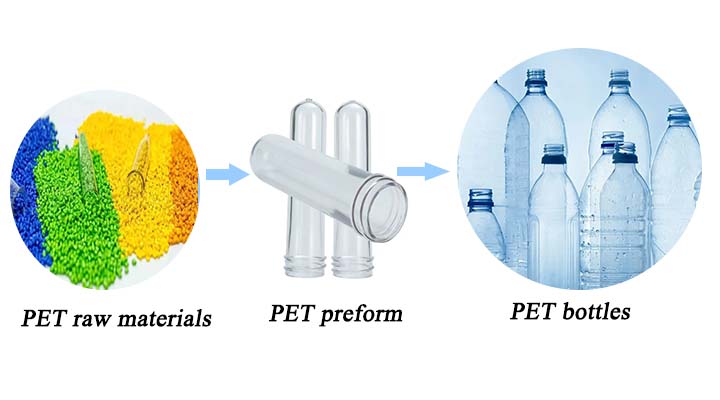

Mineral water bottles and carbonated beverage bottles are generally made of PET. PET plastic bottles usually adopt by a two-step method, that is, firstly, the plastic raw materials are processed into PET preforms by an PET preform making machine, and then the preforms are blown by a PET bottle blowing machine. Therefore, PET preform is an intermediate for making PET plastic bottles. So why should the plastic be processed into an intermediate preform first, instead of directly processed into a finished plastic bottle? What are the advantages of using PET material?

Why process into preforms first?

There are three main reasons for first processing plastic raw materials into PET preforms and then blowing them by blowing machines.

- The molding effect is good, and the correction is simple. As an intermediate to process plastic bottles, if there are unsatisfactory places in the formed plastic bottles, it can be easily corrected, so that a large number of plastics will not become waste products.

- The manufacture is simple and the effect is good. After processing into PET preforms, you only need to put the preforms into the mold of the blow molding machine to blow out the shape. Different shapes of plastic bottles can be blown out of PET preforms of the same size through different molding dies.

- Reduce workload and save costs. Whether it is processing PET preforms or making moldings, these two steps are relatively simple, which not only saves work costs, but also reduces workload.

What are the advantages of PET material?

- PET plastic has the characteristics of light texture, high transparency, impact resistance and not easy to break.

- Using PET bottles as containers for mineral water, beverages, etc., can block carbon dioxide gas and keep the soda aerated

- PET bottles have a wide range of applicability and are widely used in daily necessities, medicine, daily chemical packaging, reagents, etc.

- It is a milky white or pre-yellow highly crystalline polymer with a smooth and glossy surface.

- It has very good physical and chemical properties. Good insulation performance, less affected by temperature, weak acid resistance, etc.