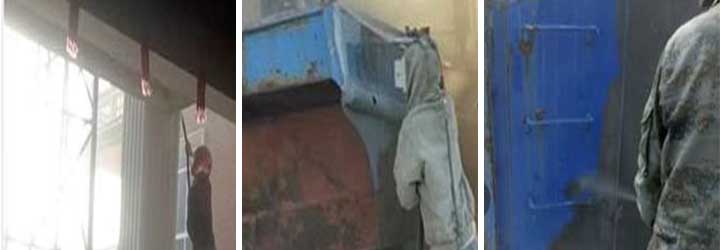

Before finishing the workpiece, it generally needs to process the surface of the workpiece. Sand blasting is a frequently used method for workpiece treatment by using the automatic sandblasting machine. Sand blasting uses abrasive to impact and cut the workpiece surface, so that the workpiece surface can obtain a certain degree of cleanliness and roughness. Therefore, sand blasting can change the performance of the workpiece and enhance the performance of the workpiece surface. Sand blasting is widely used in aviation parts, shipbuilding, mold processing and so on. The sand blasting process includes wet sand blasting and dry sand blasting. Next to introduce you wet sandblasting VS dry sandblasting,and let us check what is the difference.

Dry sand blasting

Dry sand blasting is the most traditional way of sand blasting, which is cheaper than wet sand blasting. It is that the sand blasting machine sprays the abrasive to the surface of the workpiece at a high speed through compressed air. The rust layer is removed by impact and friction. The dry sand blasting method will produce large dust in work, which has certain requirements for the environment. Dry sand blasting will produce sparks in the work, so it can no longer be used in flammable and explosive places.

Wet sand blasting

The wet sand blasting method is to mix the abrasive and water according to a certain proportion, and then spray it to the object surface through the grinding liquid pump and compressed air for processing. The spray gun sprays the grinding fluid onto the object surface, which can clean and polish the part surface. The whole wet sand blasting process adopts fully closed operation, and the grinding fluid works circularly without dust. Therefore, the wet sand blasting method has low requirements for the working environment and will not produce pollution.

Wet sandblasting VS dry sandblasting

| Dry blasting | Wet sandblasting | |

| Working premise | Direct abrasive blasting | Sand blasting shall not be carried out until the abrasive is mixed with water |

| working principle | Compressed air ejects abrasive at high speed | The grinding liquid pump and compressed air spray the grinding liquid to the object surface at high speed through the spray gun |

| Impact on the environment | It causes a lot of dust and has high requirements for the environment | It will not produce dust, discharge toxic wastewater and pollute the environment |

In addition, Yugong construction machinery manufacturer also compared the difference between sand blasting and shot blasting. If you are interested, please click to check. Yugong machinery provides dry and wet sand blasting machines and shot blasting machines for treating object surfaces. If you are interested in any of the above machines, please leave a message below or leave WhatsApp message.