Telescopic boom concrete laser screed machine is a high-tech construction device used to level and vibrate fresh concrete in a single pass. Compared to ordinary concrete laser screeds, the boom-integrated version offers a significant advantage in reach and maneuverability. By utilizing a 360-degree rotating platform and an extendable arm, these machines can cover massive surface areas without the need for constant repositioning on the wet concrete. It is designed to meet the highest standards of floor flatness and floor levelness, which are critical for warehouses with high-reach forklifts, automated logistics centers, and high-tech manufacturing plants.

YG-ZP30 Telescopic Boom Concrete Laser Screed Parameters

| Model | YG-ZP30 |

| Engine brand model | Yanmar 4TNV94L |

| Type | Diesel |

| Power | 35.5KW/48hp |

| Fuel tank volume | 100L |

| Hydraulic oil volume | 150L |

| Hydraulic system | Danfoss |

| Laser transmitter | American Tempo |

| Laser receiver | German Mopar |

| Laser system control effect | Flat, inclined or double slope (3D) |

| Laser system control method | Microcomputer laser scanning |

| Trapping method | Hydraulic Cage Paving |

| Auger power | Hydraulic motor |

| Advantages of Jiaobanlong | Flip up and down for easy cleaning, left and right switching, blades made of highly wear-resistant material, more durable |

| Reach length | 6000mm |

| Vibrating plate width | 3100mm |

| Leveling thickness | 100-450mm |

| Walking weight/working speed | 4-8km/h 24m/min |

| Walking drive form | Hydraulic four-wheel drive Outrigger |

| Steering method | One-touch four-leg self-leveling |

| Walking tires | Front wheel + four wheels + crab walk |

| Cleaning machine flow | 15L/min |

| Body size | 5350x3650x2040mm |

| Weight | 5500 kgs |

Features of Telescopic Boom Concrete Laser Screed Machine

- High Precision Laser Control: The heart of the machine lies in its laser receivers. These sensors capture signals from a stationary laser transmitter at a frequency of several times per second. This ensures that the screed head automatically adjusts its height to maintain a perfectly level plane, regardless of the terrain or the movement of the chassis.

- 360 Degree Rotating Platform The ability to rotate the upper structure 360 degrees allows operators to reach every corner of a pour site. This rotation, combined with the telescopic boom, means the machine can stay on solid ground or finished slabs while reaching over the freshly poured concrete.

- Automated Screeding Head: The screed head is a complex assembly that includes an auger to remove excess concrete, a vibrator to consolidate the material, and a finishing blade to smooth the surface. All these components work in harmony under the command of the onboard computer.

- Heavy Duty Stabilizers: To maintain precision during boom extension, these machines are equipped with robust outriggers. These stabilizers ensure that the machine remains level and vibration-free, even when the boom is fully extended to 6 or 9 meters.

Main Applications In The Industry

The versatility of the telescopic boom concrete laser screed machine makes it indispensable across various sectors.

- Industrial Warehousing: Logistics hubs require floors that can support heavy loads and allow high-speed forklift operation. Any minor deviation in floor levelness can cause a forklift to tilt or sway at high heights. This machine ensures the precision required for such environments.

- Commercial Parking Garages: Multi-story parking structures benefit from the speed of laser leveling. The machine can handle large pours quickly, reducing the number of cold joints and improving the structural integrity of the deck.

- Airport Runways And Hangars: Aviation surfaces require extreme durability and flatness. The telescopic boom allows consistent leveling over wide strips, which is essential for aircraft safety during takeoffs and landings.

- Exhibition Centers and Sports Arenas: Large public spaces require aesthetic and functional perfection. The laser screed provides a finish that minimizes the need for extensive secondary grinding or polishing.

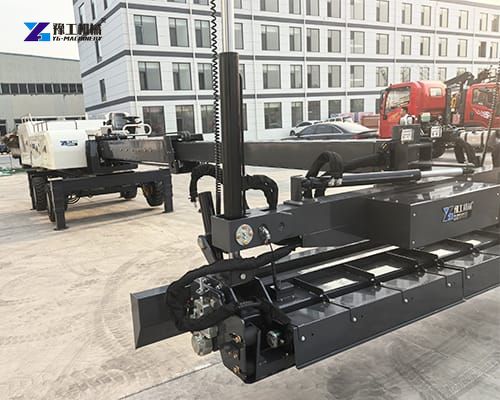

Structure Telescopic Boom Concrete Laser Leveling Machine

- The Chassis and Drive System: Usually powered by a high-torque diesel engine. The chassis features four-wheel drive and four-wheel steering. This allows the telescopic boom concrete laser screed machine to move through muddy or cluttered jobsites with ease.

- The Telescopic Boom: Constructed from high-strength alloy steel, the boom is the primary reach mechanism. It uses hydraulic cylinders to extend and retract smoothly. The internal routing of hydraulic lines protects them from concrete splatter and physical damage.

- The Laser Control System: This includes the laser transmitter (set up on a tripod away from the machine), two laser receivers mounted on the screed head, and a control console in the operator’s cabin.

- The Screed Head Assembly: This is where the work happens. It consists of:

The Plow: Pushes the initial pile of concrete.

The Auger: Moves excess concrete to the side to prevent buildup.

The Vibrator: Operates at high frequencies to eliminate air pockets.

The Leveling Blade: The final contact point that creates the smooth surface.

Working Principle and Operational Workflow

The telescopic boom concrete laser screed machine operates through a systematic workflow that integrates technology and mechanical action:

- Setup and Calibration: Operators position the machine over the work area and calibrate the laser system to establish the reference plane. This step ensures alignment with the project’s elevation requirements.

- Laser Projection and Sensing: The laser transmitter projects a horizontal or sloped plane, depending on project specifications. Sensors mounted on the machine detect the concrete surface’s position relative to this plane.

- Automatic Adjustment and Leveling: Based on sensor feedback, the control system adjusts the screed blade’s height to maintain the desired elevation. The telescopic boom’s movement is coordinated to ensure consistent coverage across the entire area.

- Continuous Monitoring and Optimization: Throughout the operation, the system continuously monitors performance, making real-time adjustments to compensate for variables such as concrete consistency, slope changes, or uneven terrain.